Releasing impurities from calcium-based mineral

A mineral, calcium-based technology, used in calcium/strontium/barium compounds, calcium/strontium/barium oxides/hydroxides, ammonia compounds, etc., can solve the problems of expensive materials, increased maintenance costs, and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

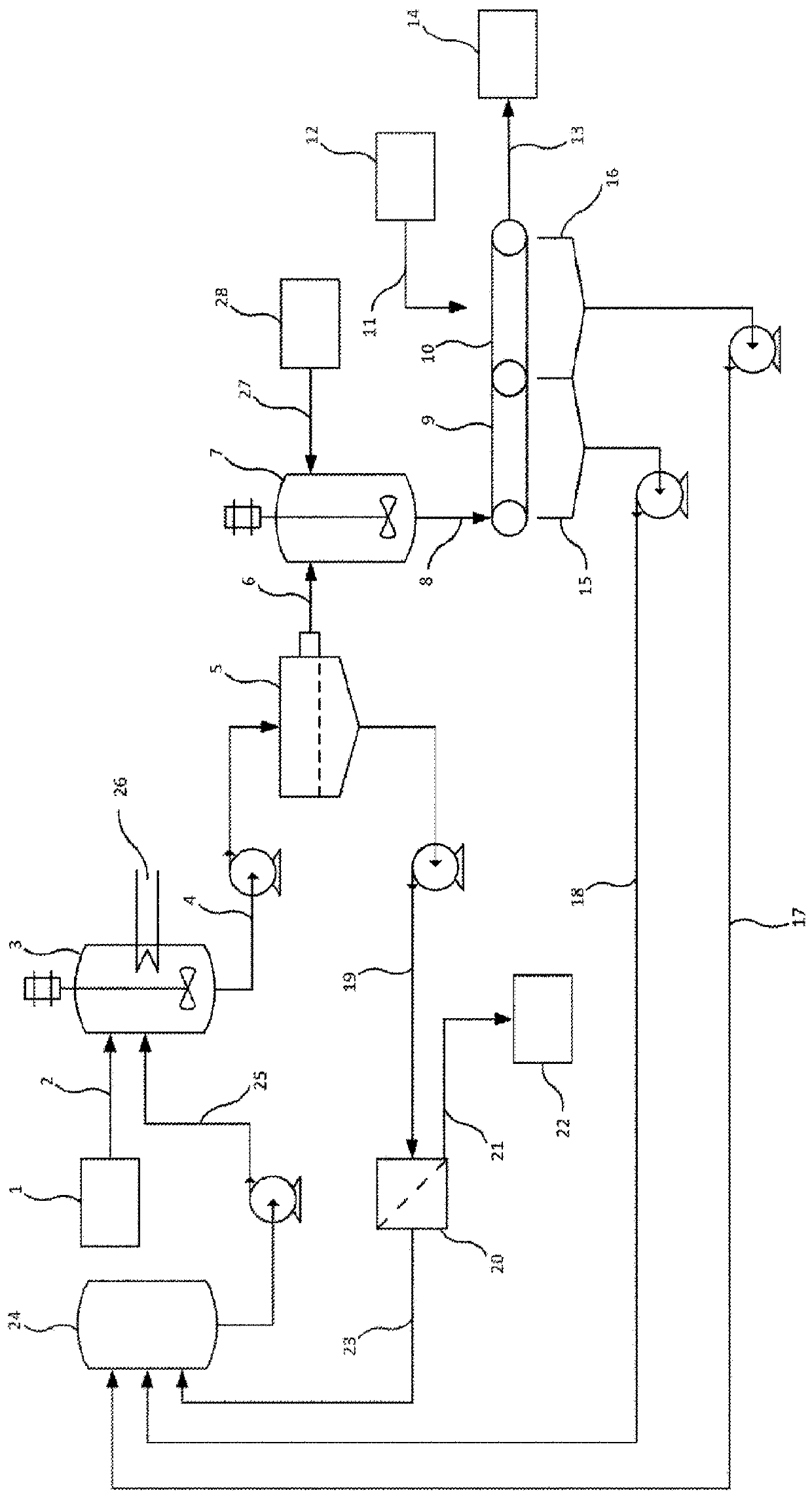

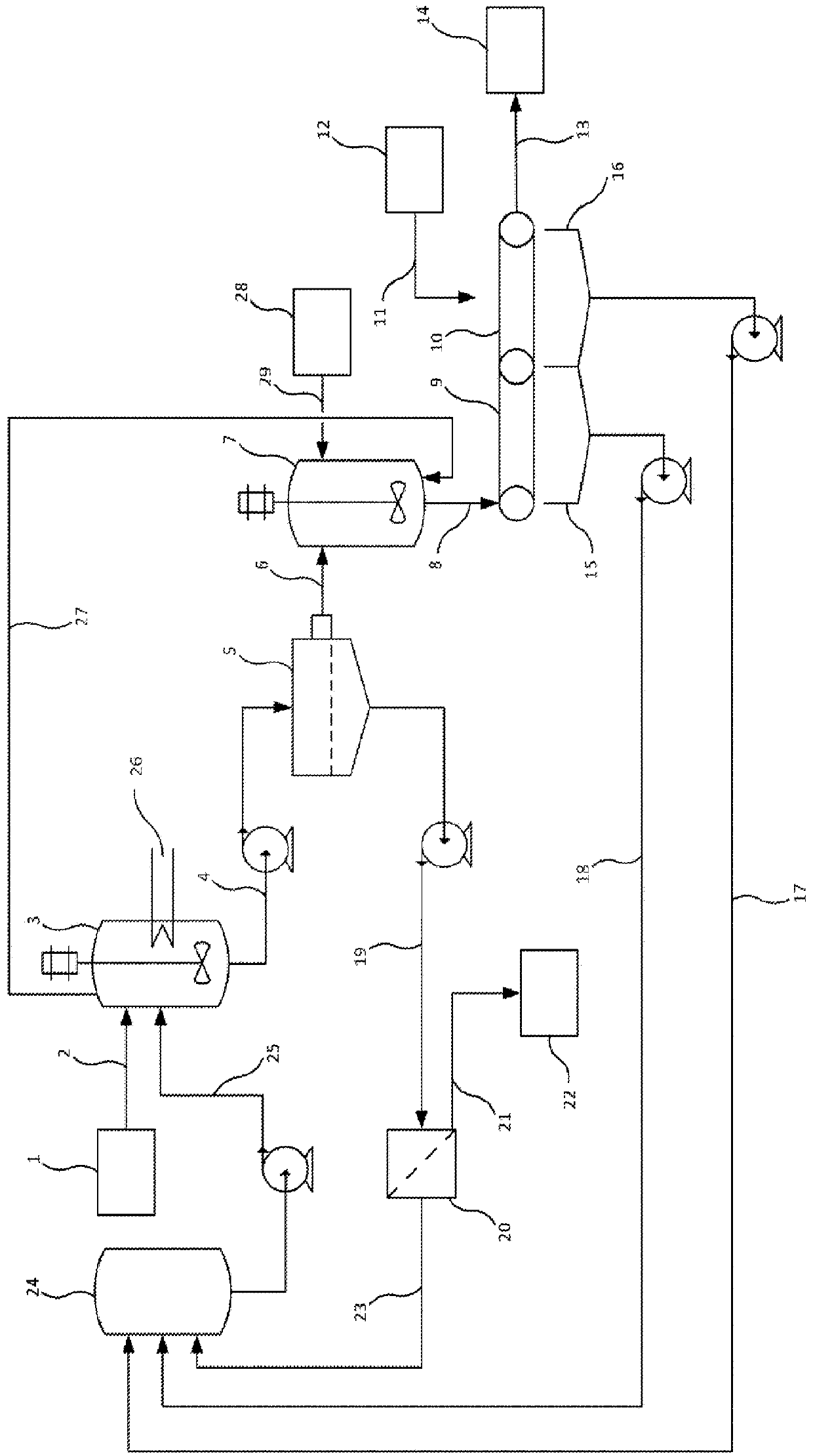

Image

Examples

Embodiment 1

[0117] Example 1: Effect of Salt Concentration.

[0118] The gypsum used in this example came from the mine and was ground to a particle size of less than 250 microns and an initial brightness value of 64.2%.

[0119] Tested under the following conditions:

[0120] The salt used in the ionic saline solution is ammonium sulfate.

[0121] Gypsum – 50g

[0122] Temperature – 102°C

[0123] Water Ratio – 1:10

[0124] Dwell time – 30 minutes

[0125]

[0126]

[0127] It is observed that the impurity layer is significantly darker from the concentration of 30% and higher.

[0128] It is believed that the resulting final brightness is optimized when the salt concentration is greater than 25%.

Embodiment 2

[0129] Example 2: Effect of temperature.

[0130] The gypsum used in this example came from the mine and was ground to a particle size of less than 250 microns and an initial brightness value of 64.2.

[0131] Tested under the following conditions:

[0132] Gypsum – 50g

[0133] Salt concentration – 40%

[0134] Water Ratio – 1:10

[0135] Dwell time – 30 minutes

[0136] temperature(℃) Final Brightness (%) 20 64.4 81 76.5 92 88.2 102 93.3

[0137] It is observed that the impurity layer is significantly darker from 92 °C and higher temperatures.

[0138] It is believed that the resulting final brightness is optimized at temperatures of 92°C and higher. However, it has been shown that a temperature of about 85°C will yield a brightness of about at least 80-85%, which may equate to a purity of about 90%, and thus may be sufficient for some uses.

Embodiment 3

[0139] Example 3: Effect of the ratio of gypsum to water.

[0140] The gypsum used in this example came from the mine and was ground to a particle size of less than 250 microns and an initial brightness value of 64.2.

[0141] Tested under the following conditions:

[0142] Gypsum – 50g

[0143] Salt concentration – 40%

[0144] Temperature – 102°C

[0145] Dwell time – 30 minutes

[0146] ratio Final Brightness (%) 1:2 89.2 1:5 90.1 1:10 93.3 1:20 97.4

[0147] It is believed that increasing the ratio of ammonium sulfate solution to gypsum improves the brightness of the resulting gypsum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com