Improved flour and preparation method thereof

A technology of flour and improver, which is applied in the direction of food ingredients as taste improver, grain milling, agriculture, etc. It can solve the problems of flour color, quality gluten and chewiness that cannot meet the requirements, and achieve good texture and taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] A preparation method for improved flour, comprising the steps of:

[0053] The first step is to wash and dry the wheat grains;

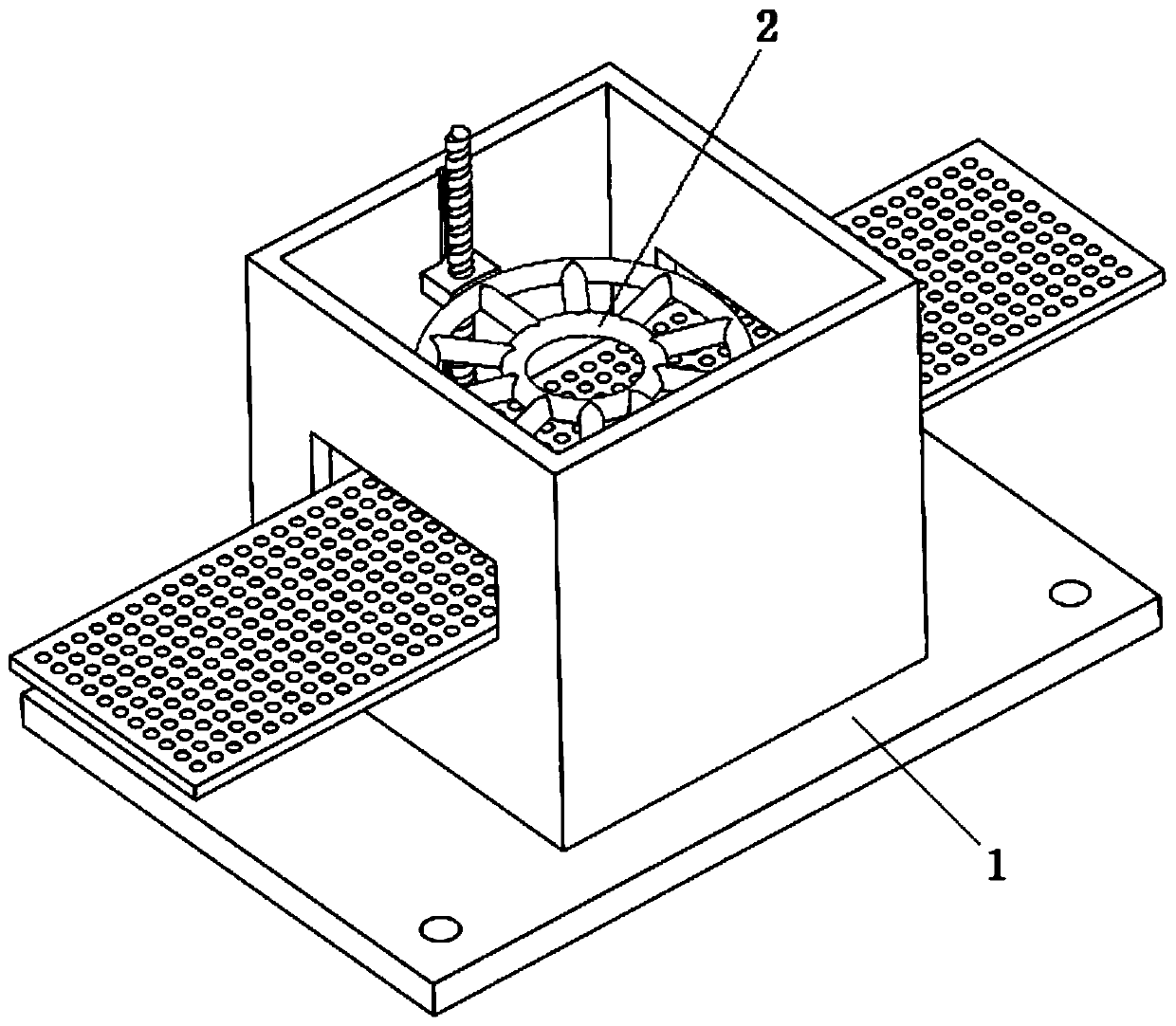

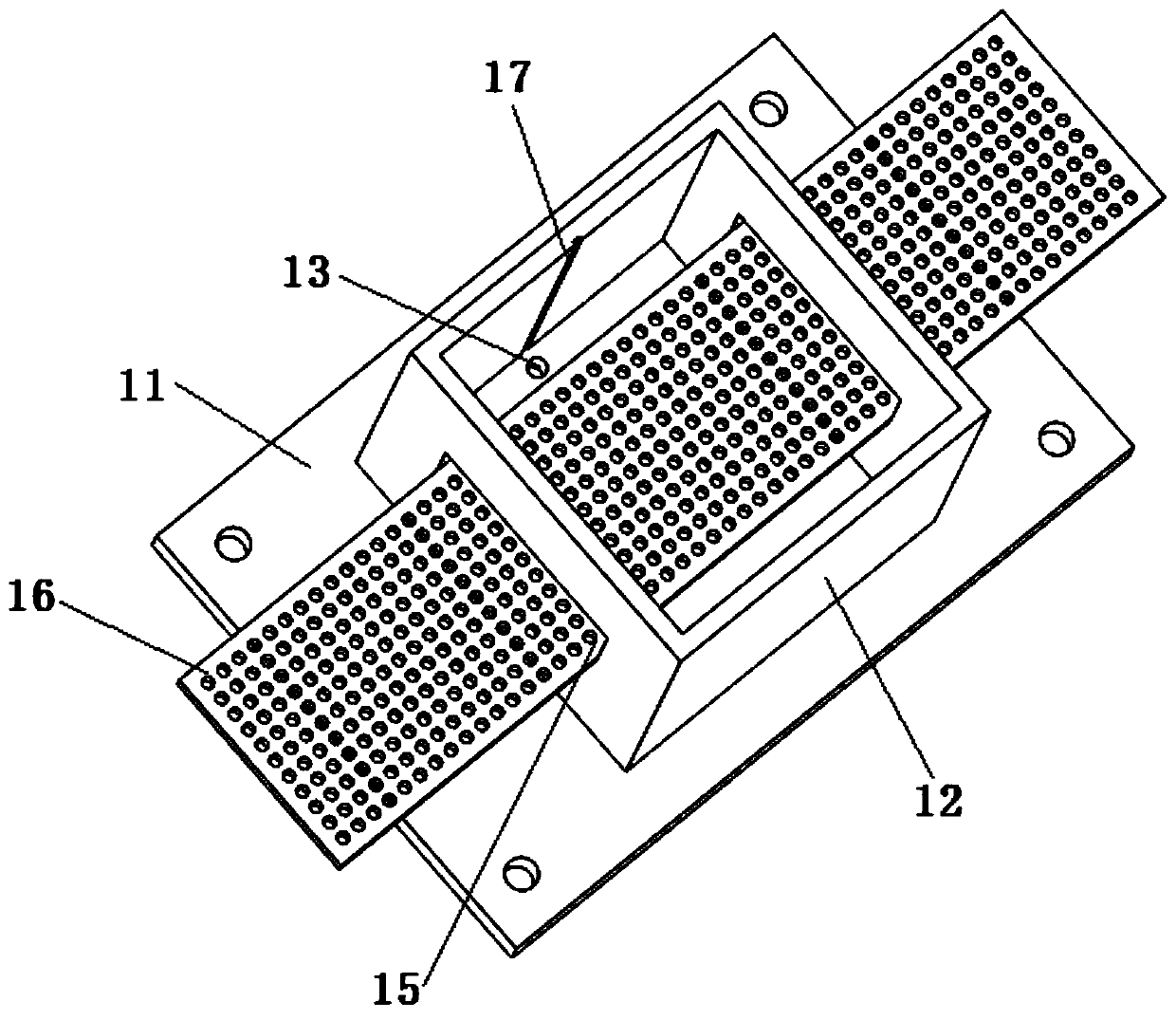

[0054] The second step is to use the wheat grain pretreatment device to pretreat the wheat grain, and the specific steps are as follows:

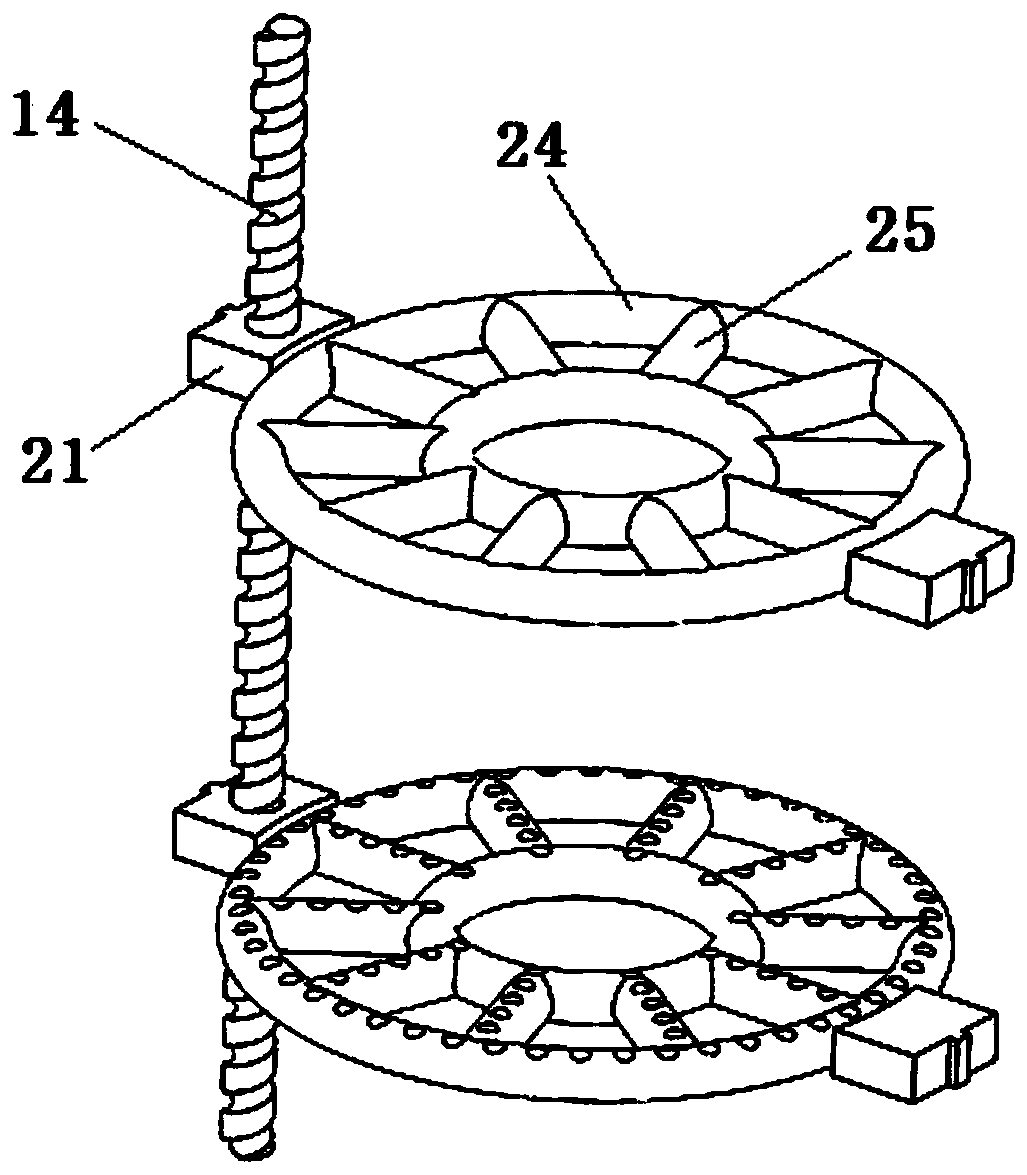

[0055] S1, the wheat is placed on the conveyer belt 16, the transmission speed of the conveyer belt 16 is set, so that the time for the wheat grain to stay in the processing chamber 12 is 3min;

[0056] S2. Turn on the motor connected to the threaded shaft 14, adjust the distance between the steam mechanism and the conveyor belt 16, and set the temperature of the steam in the steam box to 170°C;

[0057] S3, open the valve of the steam box and the first steam ring pipe 24, and set the flow rate of the steam out of the steam box to be 20m 3 / h, complete the pretreatment of the wheat grains in the processing bin 12 to obtain the pretreated wheat grains;

[0058] The third step is to place the pretreated wh...

Embodiment 1

[0071] An improved flour is made from the following raw materials in parts by weight: 80 parts of wheat grains, 16 parts of superfine wheat bran, and 0.6 parts of improver;

[0072] The improved flour is made by the following steps:

[0073] The first step is to wash and dry the wheat grains;

[0074] The second step is to use the wheat grain pretreatment device to pretreat the wheat grain, and the specific steps are as follows:

[0075] S1, the wheat is placed on the conveyer belt 16, the transmission speed of the conveyer belt 16 is set, so that the time for the wheat grain to stay in the processing chamber 12 is 3min;

[0076] S2. Turn on the motor connected to the threaded shaft 14, adjust the distance between the steam mechanism and the conveyor belt 16, and set the temperature of the steam in the steam box to 170°C;

[0077] S3, open the valve of the steam box and the first steam ring pipe 24, and set the flow rate of the steam out of the steam box to be 20m 3 / h, compl...

Embodiment 2

[0081] An improved flour is made from the following raw materials in parts by weight: 90 parts of wheat grains, 18 parts of superfine wheat bran, and 0.8 parts of improver;

[0082] The improved flour is made by the following steps:

[0083] The first step is to wash and dry the wheat grains;

[0084] The second step is to use the wheat grain pretreatment device to pretreat the wheat grain, and the specific steps are as follows:

[0085] S1, the wheat is placed on the conveyer belt 16, the transmission speed of the conveyer belt 16 is set, so that the time for the wheat grain to stay in the processing chamber 12 is 3min;

[0086] S2. Turn on the motor connected to the threaded shaft 14, adjust the distance between the steam mechanism and the conveyor belt 16, and set the temperature of the steam in the steam box to 170°C;

[0087] S3, open the valve of the steam box and the first steam ring pipe 24, and set the flow rate of the steam out of the steam box to be 20m 3 / h, com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com