Processing production line of gas meter housing

A gas meter and assembly line technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, liquid spraying equipment, etc., can solve the problems of difficult product quality control, high labor intensity, low production efficiency, etc., to reduce processing equipment and improve processing Efficiency, effect of reducing processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

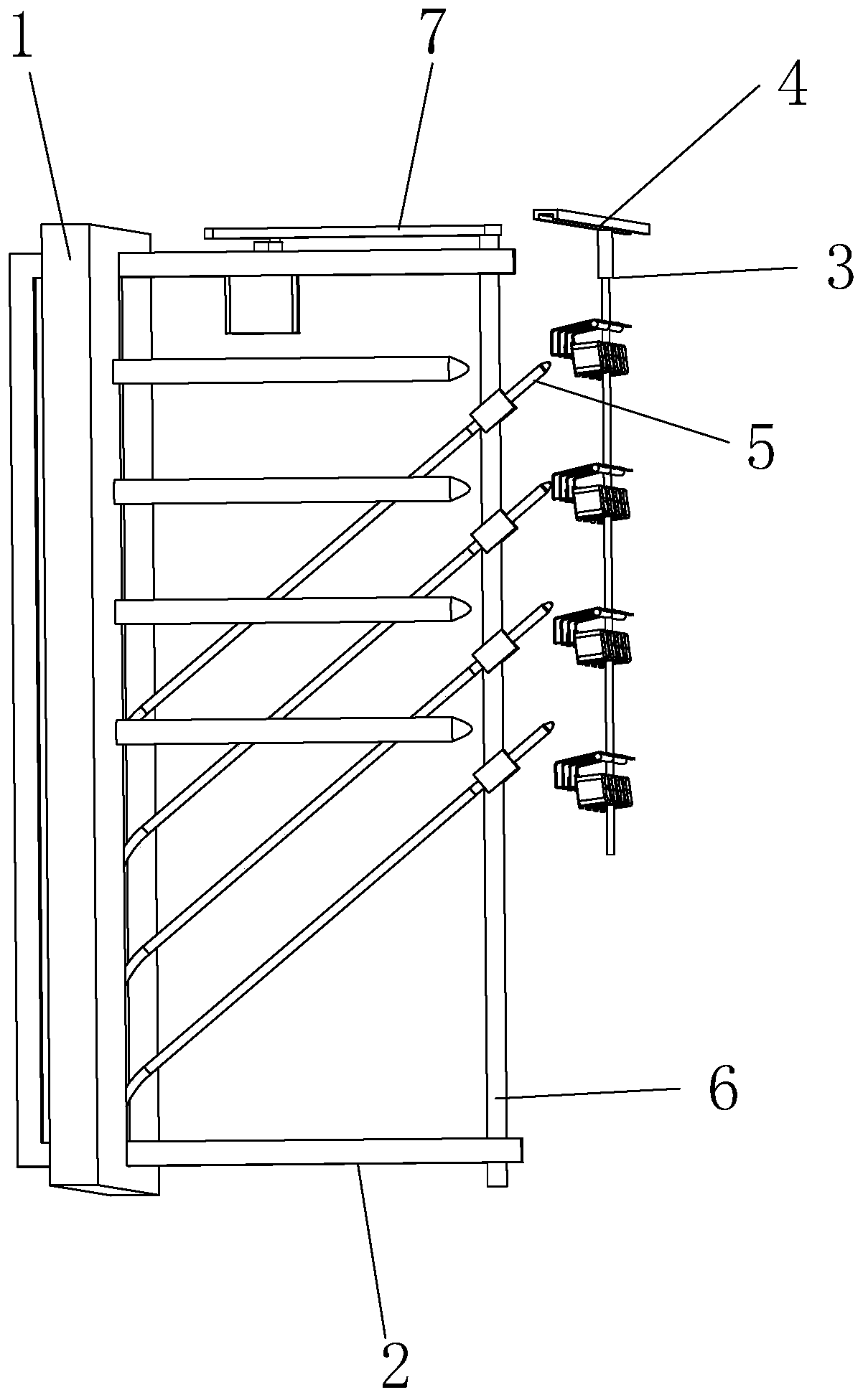

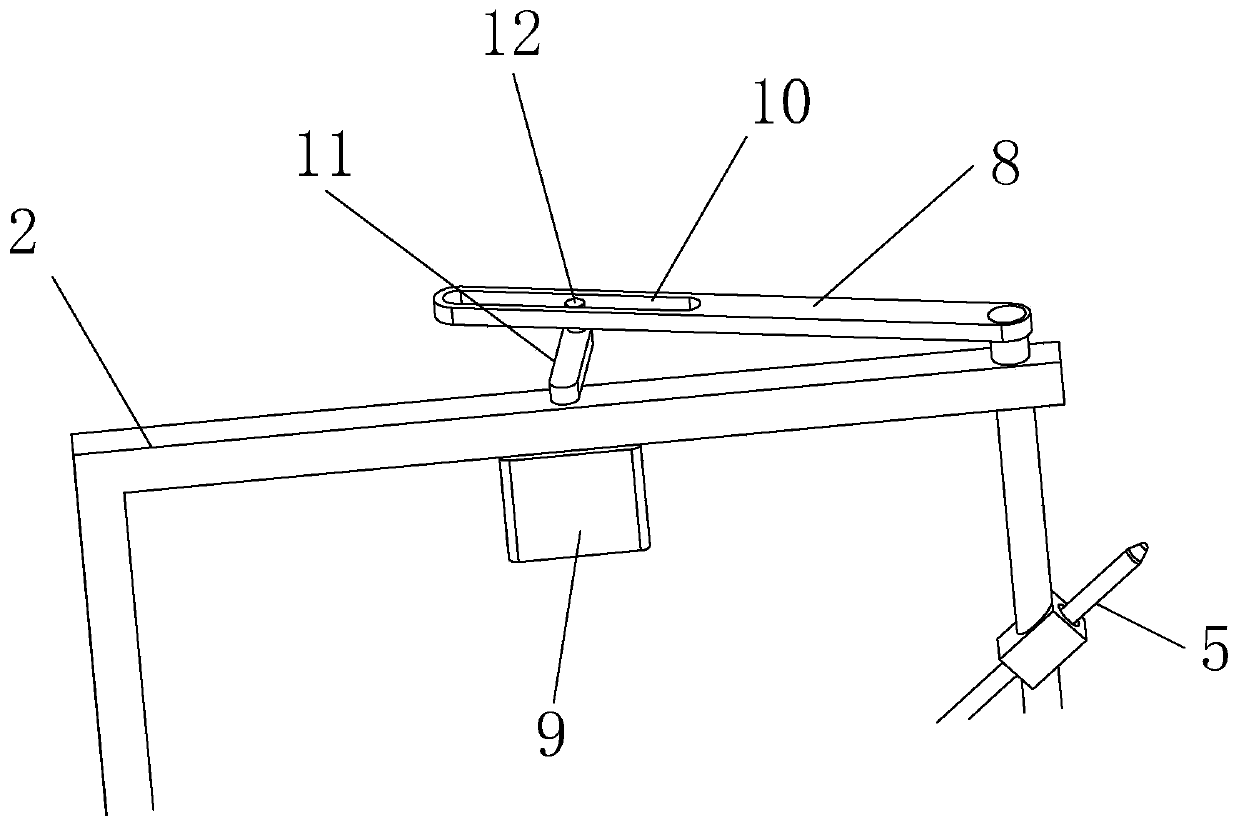

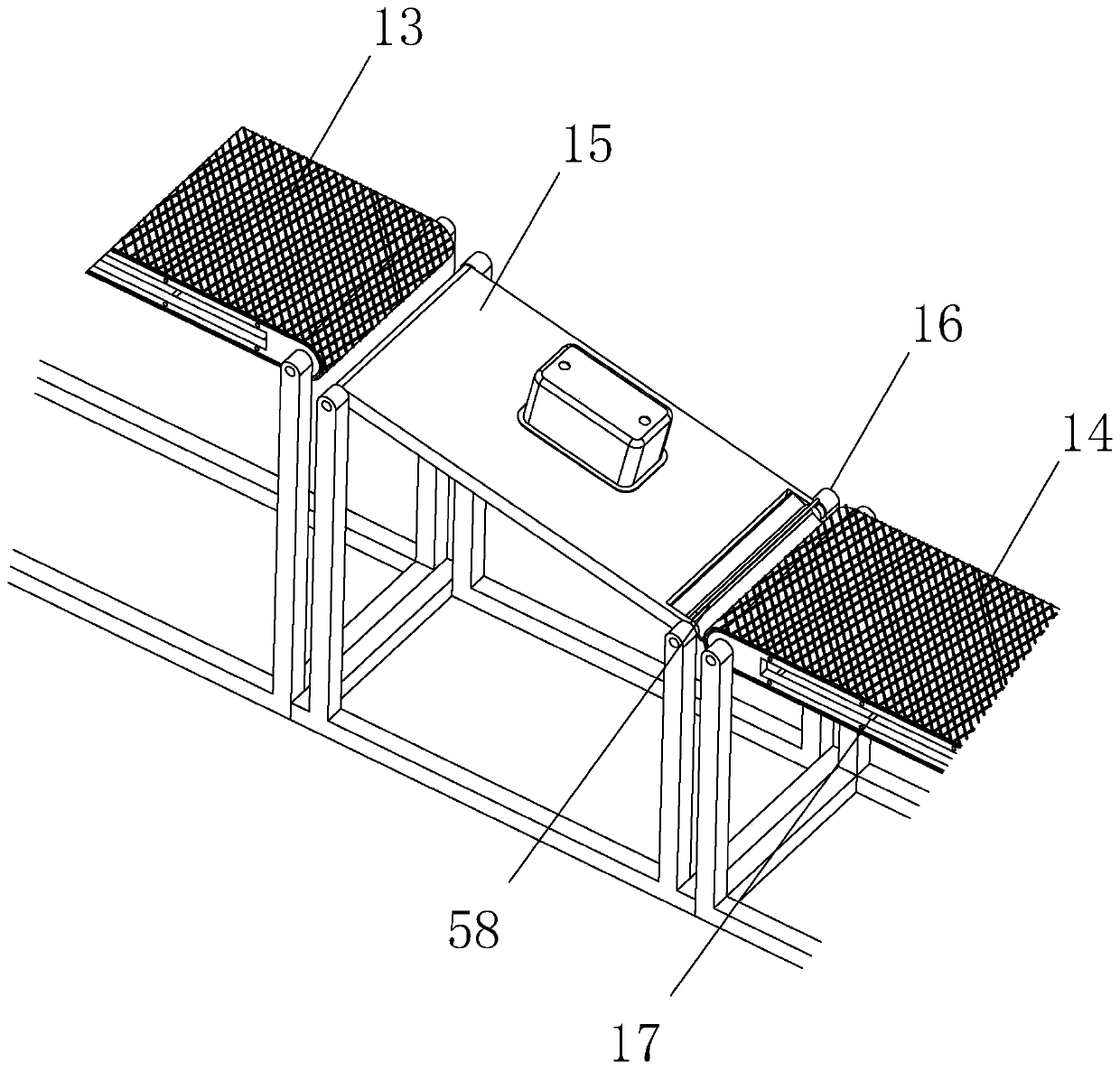

[0045] like figure 1 As shown, a device for repairing plastic injection guns for gas watch cases includes a fixed plate 1, a mobile bracket 2, a plastic spray gun 5, a transmission belt 4, and a suspension bracket 3. A plurality of suspension brackets 3 are hung on the conveyor belt at intervals, and fixed The board 1 is located on one side of the suspension bracket 3 queue, and the fixed board 1 is fixedly provided with a plurality of suction guns, the muzzle of the suction gun is located on the side of the plastic spray gun 5 facing the suction gun, and the mobile bracket 2 is slidably arranged on the fixed On the plate 1, a rotating shaft 6 is arranged on the movable support 2, the plastic spraying gun 5 is fixedly arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com