Automatic stocktaking device for wires and cables

A wire and cable, automatic technology, applied in the field of wire and cable automatic disk storage device, can solve the problems of low operation efficiency, low degree of automation, labor intensity of personnel, etc., and achieve small space occupation, high degree of automation and large storage capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

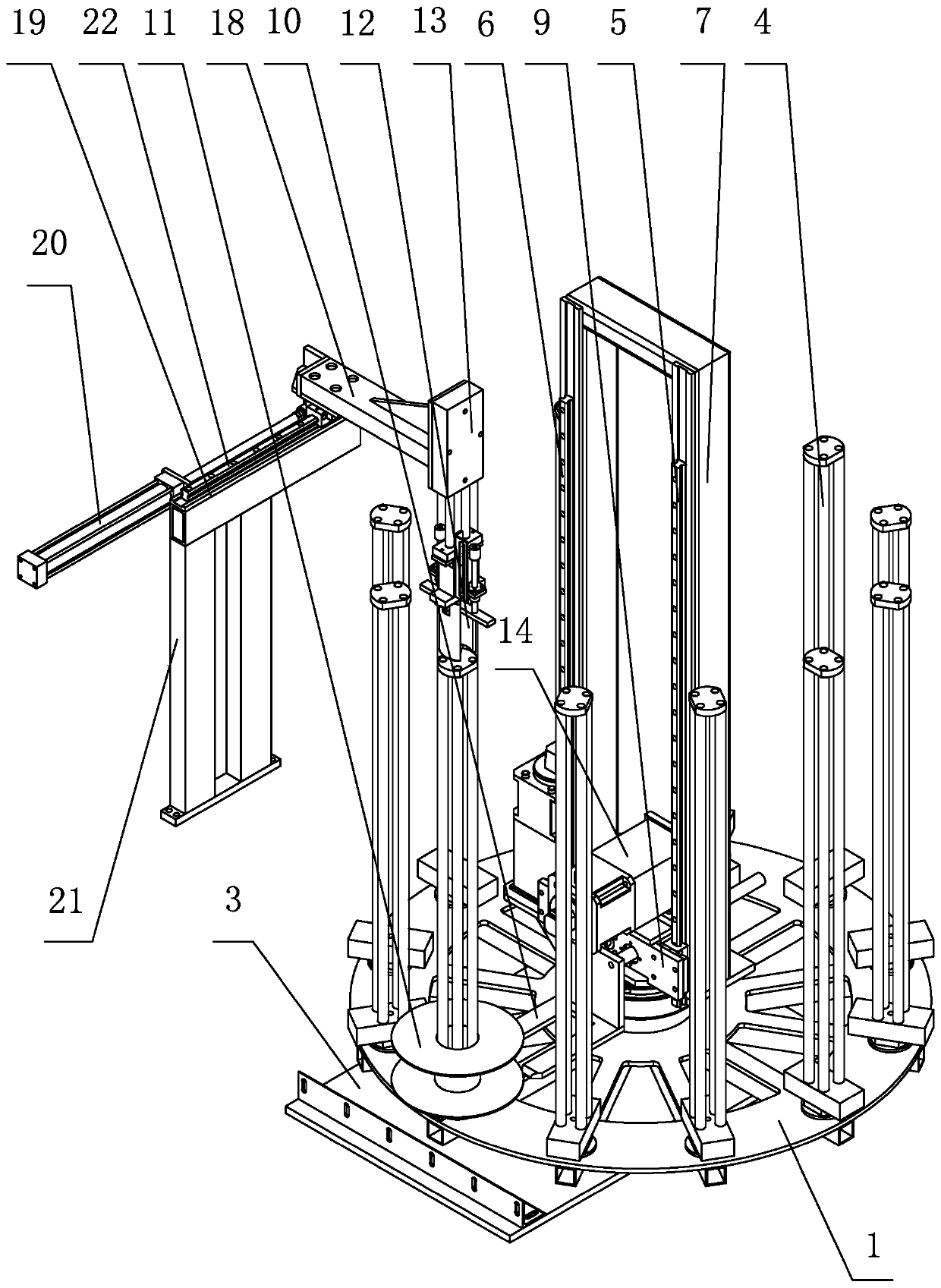

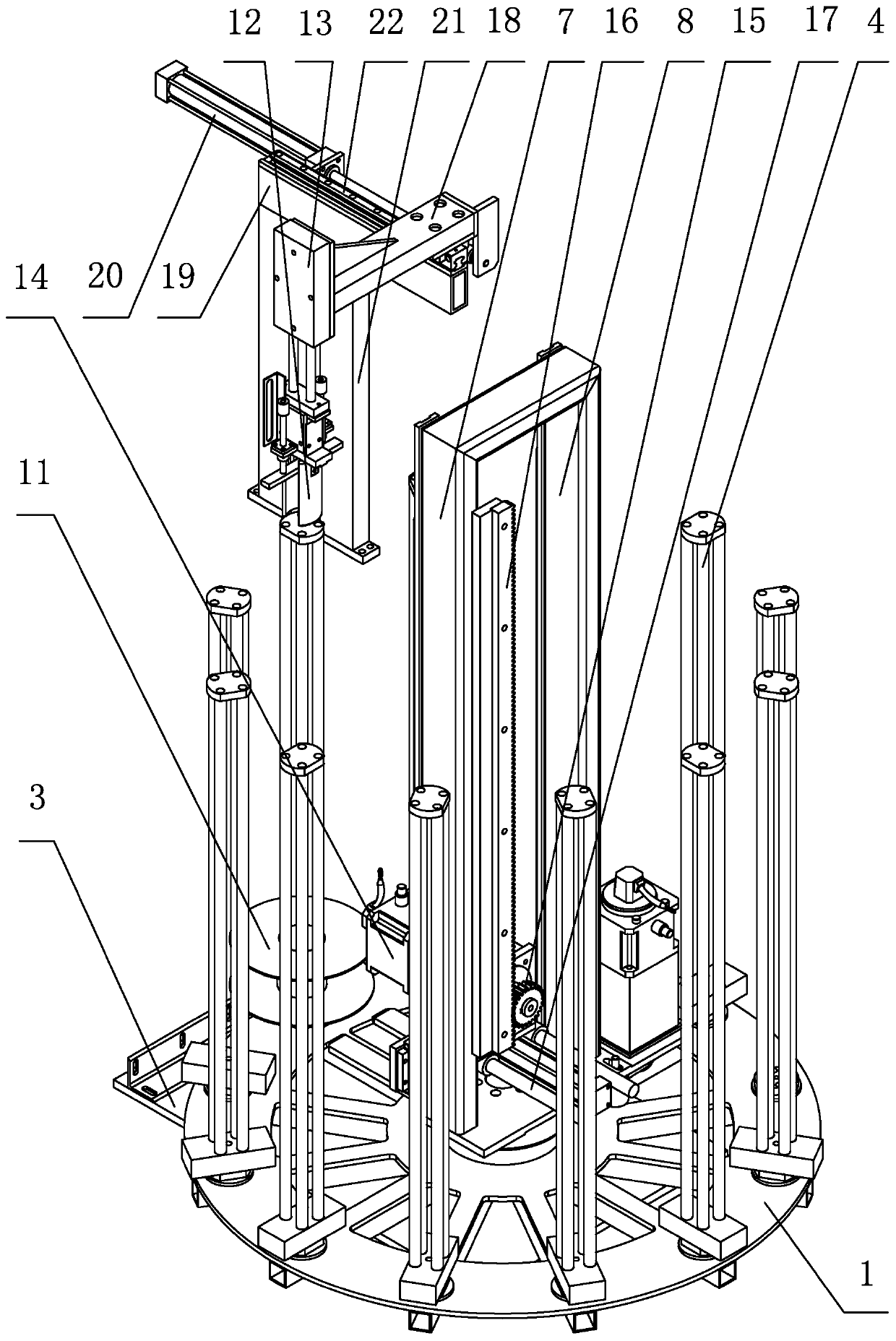

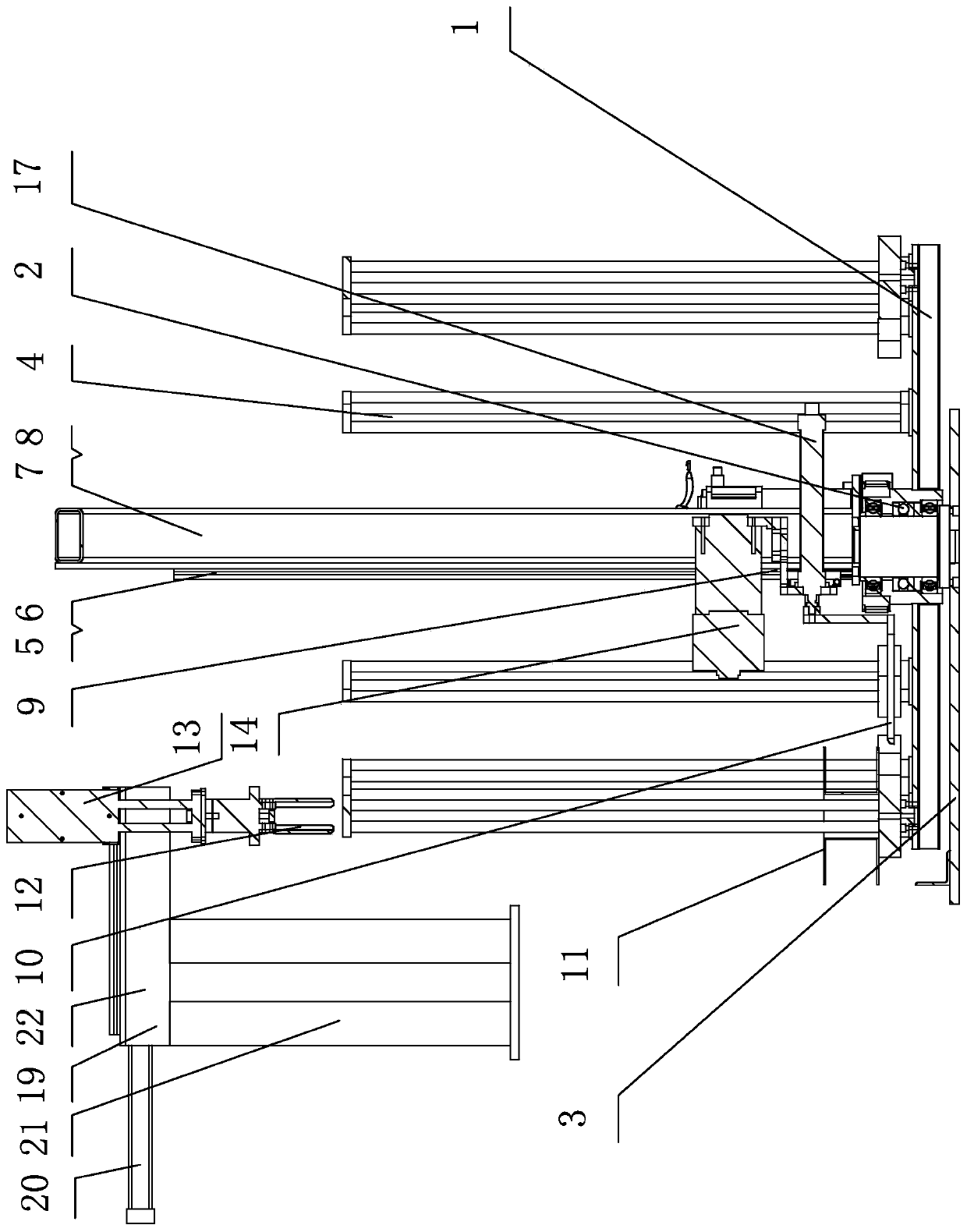

[0024] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0025] The automatic wire and cable disk storage device of the present invention includes an indexing part, a disk storage part and a disk lifting part arranged on the indexing part, and a disk fetching part arranged corresponding to the disk storage part.

[0026] The indexing component includes a turntable 1, and the turntable 1 is horizontally installed on the rear portion of the chassis 3 through a bearing mechanism 2, and the chassis 3 is provided with a transmission mechanism that drives the turntable 1 to rotate and index, such as figure 1 , figure 2 , image 3 , Figure 4 shown.

[0027] The storage disc member includes 12 storage rods 4 that are uniformly distributed around the circumference and vertically arranged on the edge of the turntable 1. Each storage rod 4 includes a group of 4 round rods, and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap