Exhaust gas recirculation (EGR) engine waste heat recovery system and control method thereof

A technology of engine waste heat and recovery system, applied in engine components, combustion engines, machines/engines, etc., can solve problems such as complex layout, and achieve the effect of improving recovery efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

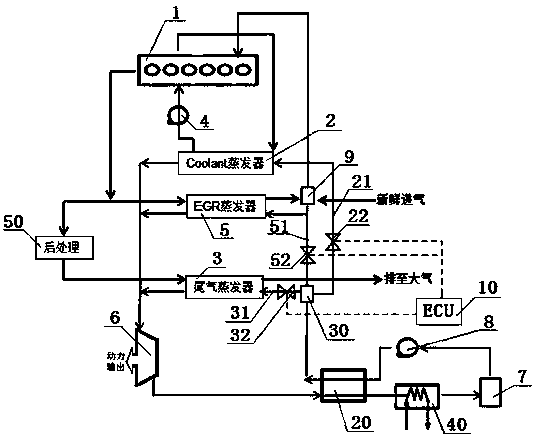

[0038] see figure 1 , a waste heat recovery system for an EGR engine, comprising an engine 1, a cooling water evaporator 2, an exhaust gas evaporator 3, an EGR evaporator 5, a liquid storage tank 7, a working medium pump 8, an EGR mixer 9, and a regenerator 20. The cooling water inlet of the cooling water evaporator 2 is connected with the cooling water outlet of the engine 1, the cooling water outlet of the cooling water evaporator 2 is connected with the cooling water inlet of the engine 1 through the cooling water pump 4, and the exhaust gas evaporator 3 The tail gas inlet is connected with the exhaust port of the engine 1 through the post-processing device 50, the tail gas outlet of the tail gas evaporator 3 is connected with the atmosphere, the EGR inlet of the EGR evaporator 5 is connected with the exhaust port of the engine 1, and the EGR evaporates The EGR outlet of the device 5 is connected with the intake port of the engine 1 through the EGR mixer 9, and the working ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap