Alcohol-based fuel heating furnace

An alcohol-based fuel and a heating stove technology, applied in the field of heating stoves, can solve the problems of high fuel cost of kerosene heating stoves, unsuitable for outdoor heating, insufficient fuel combustion, etc., and achieve the effects of good heating effect, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

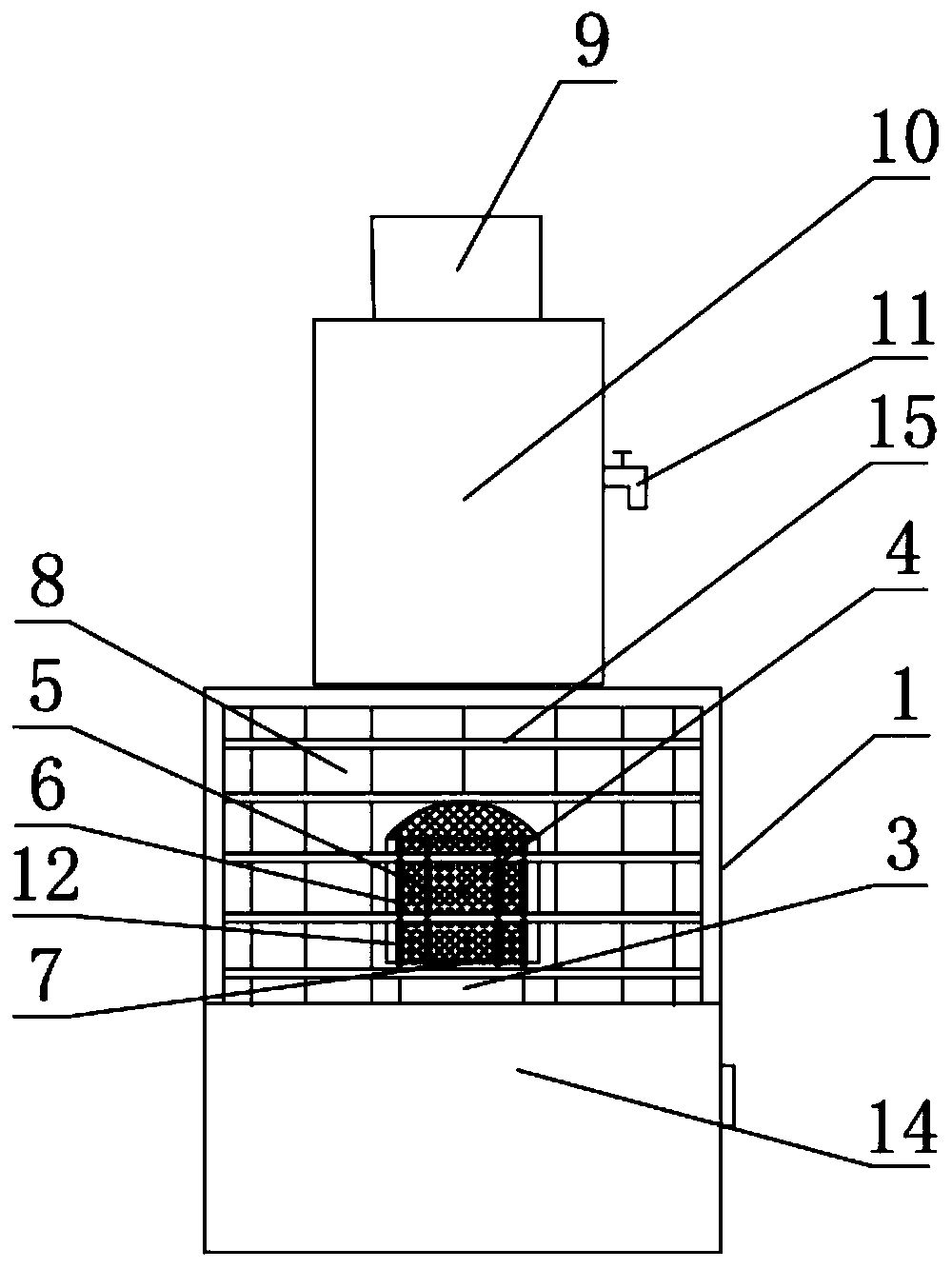

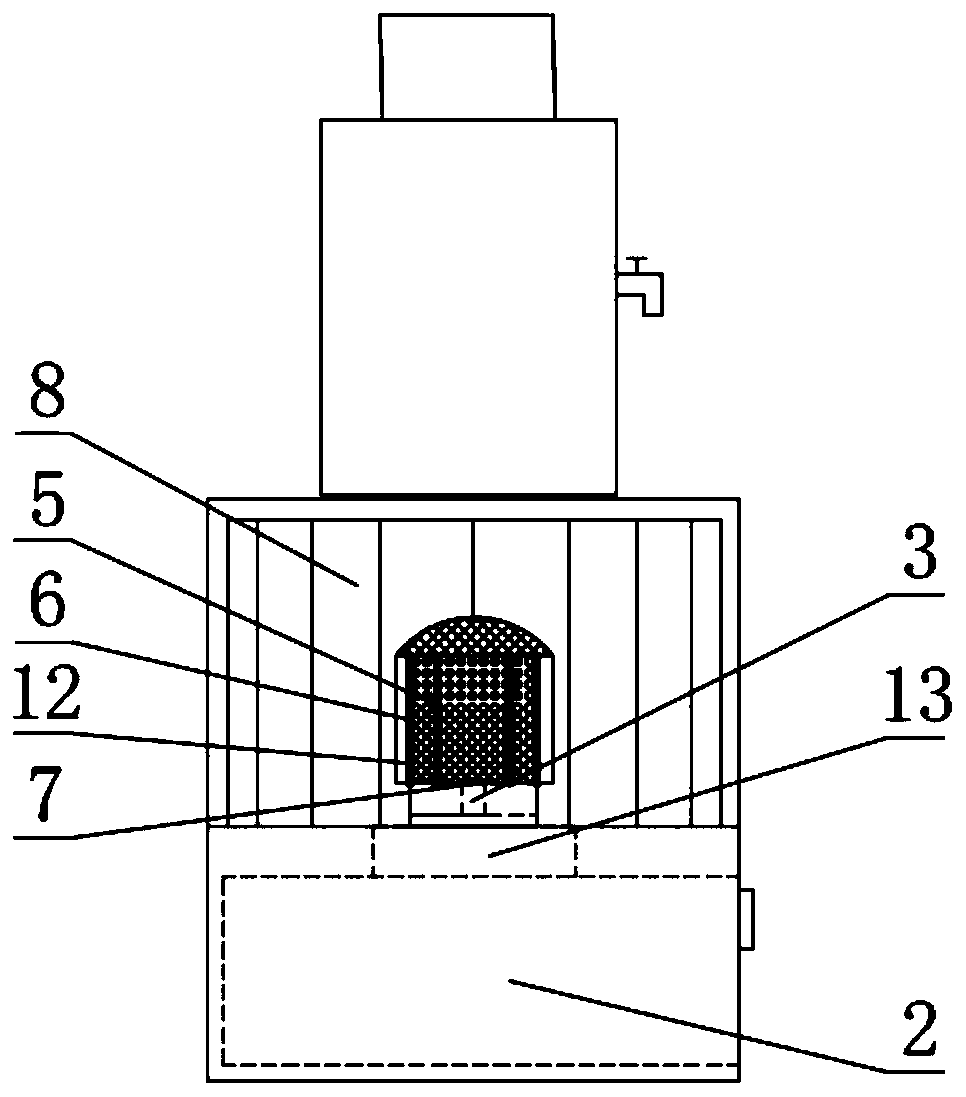

[0022] Such as figure 1 and figure 2 As shown, an alcohol-based fuel heating furnace of the present invention includes a furnace body 1, a fuel tank 2 is arranged at the bottom of the furnace cavity of the furnace body 1, and the upper part is an open structure, and the feed port of the fuel tank 2 is located in the furnace body 1 side wall, a combustion furnace is arranged above the fuel tank 2, and the combustion furnace includes a primary combustion furnace head 3 and a combustion chamber 4 above the primary combustion furnace head 3, and the discharge port of the fuel tank 2 is connected to the primary combustion furnace The feed port of the head 3 is connected, the fuel tank 2 is filled with alcohol-based fuel, the combustion chamber 4 is connected with the burner 3, and the combustion chamber 4 includes an internal combustion cylinder 5 and an external combustion cylinder 6 coaxially arranged A secondary combustion net 7 is arranged below the internal combustion cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com