Non-contact monitoring defect identification method for a contact network

A defect identification, non-contact technology, applied in character and pattern recognition, special data processing applications, instruments, etc., can solve the problem of few patent achievements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

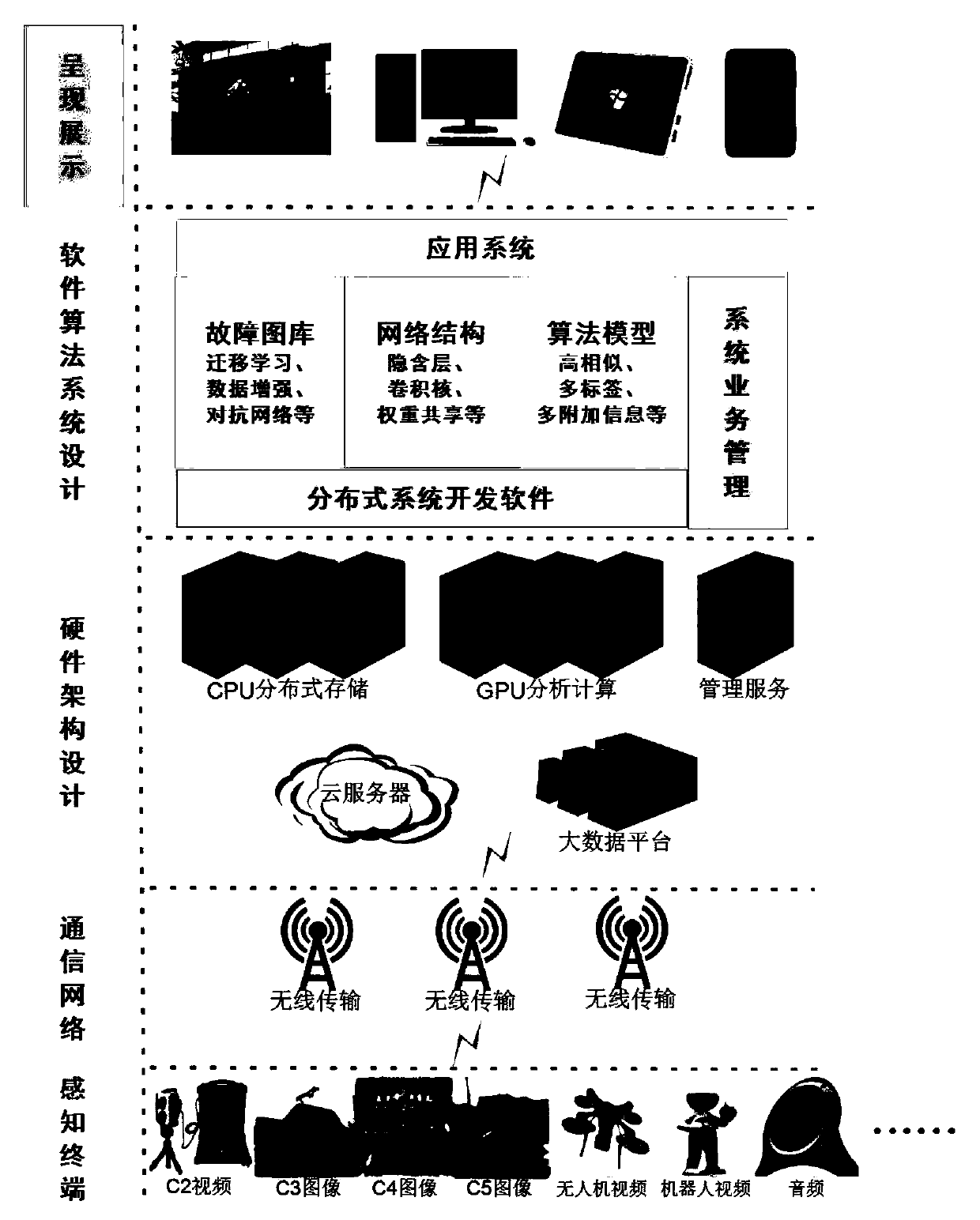

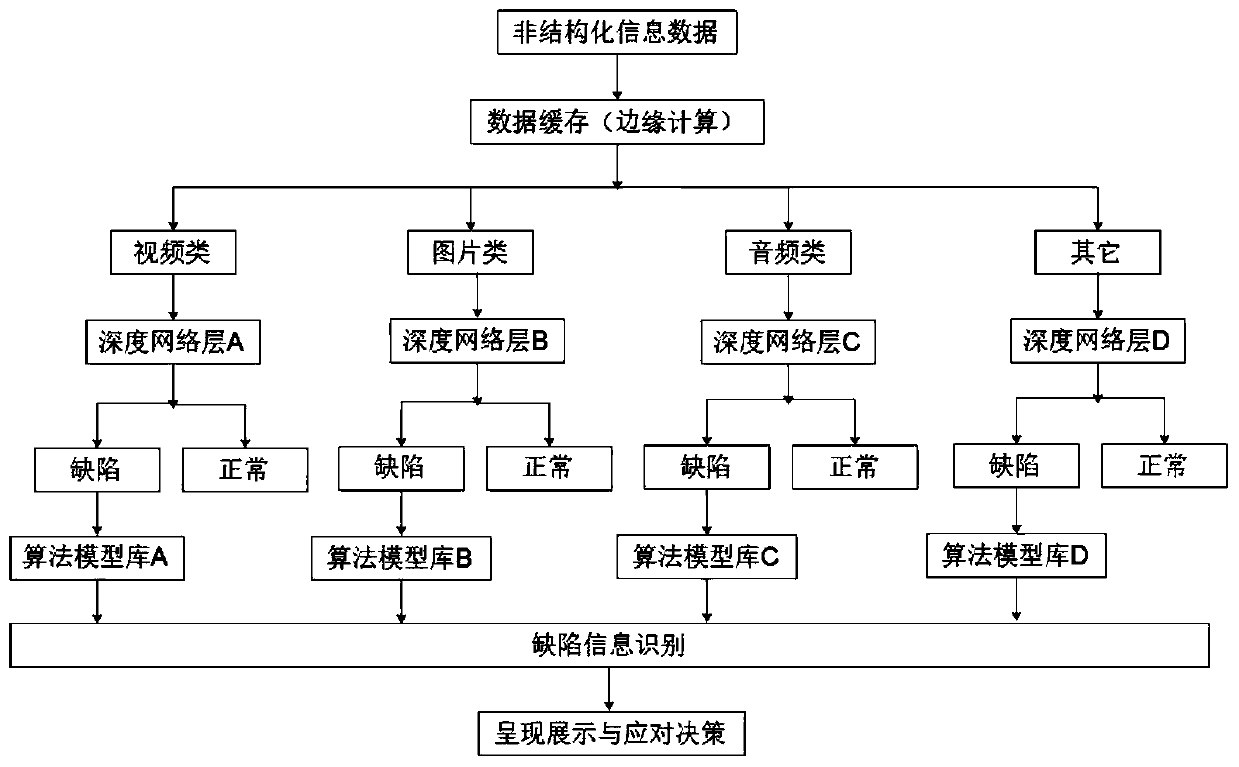

[0090] Based on the comprehensive monitoring and detection video image information data of the railway power supply 6C system, a big data analysis platform based on the GPU hardware architecture is built, and through video image processing technology and deep learning methods, the abnormal phenomena in the catenary video image data are identified and formed. A set of distributed catenary video image intelligent monitoring system.

[0091] The system includes:

[0092] (1) Sensing terminal: Cameras or cameras on operating trains or catenary operation vehicles capture catenary panoramas and partial video screens or images of components, and upload them to the local big data analysis platform or cloud based on GPU hardware architecture through advanced wireless communication technology The data processing center is stored in databases such as HBase.

[0093] (2) Communication network: The collected video or image information data along the catenary line, using the current advanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com