Flexible OLED device thin film packaging method

A thin-film packaging and device technology, which is applied in the manufacture of electrical solid devices, semiconductor devices, semiconductor/solid devices, etc., can solve the problems of poor water and oxygen barrier performance, easy cracks and falling off, serious stress mismatch, etc., to achieve Improve water and oxygen barrier performance, reduce stress, and have good packaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A thin-film packaging method for a flexible OLED device, using an inorganic / organic overlapping packaging layer, modifying the surface of the organic barrier layer of the packaging layer, and setting a sacrificial layer in the packaging structure, and the packaging structure is periodically repeated;

[0035] The packaging method comprises the steps of:

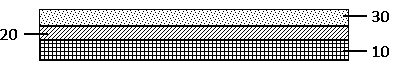

[0036] (1) As attached figure 1 As shown, a pre-prepared OLED device 10 is provided, and an inorganic barrier layer 20 is prepared on the surface of the pre-prepared OLED device 10 by atomic layer deposition;

[0037] (2) As attached figure 2 As shown, an organic barrier layer 30 is prepared on the surface of the inorganic barrier layer 20 in step (1);

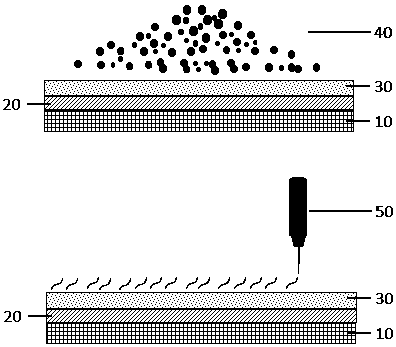

[0038] (3) As attached image 3 As shown, the surface of the organic barrier layer 20 is treated with plasma 40;

[0039] (4) As attached Figure 4 As shown, repeat steps (1) to (3) once, and then sequentially prepare the inorganic barrier layer 21 and the organi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com