Stone carving machine

A technology of engraving machine and stone, which is applied in the direction of decorative art and processing models, etc., can solve the problems of unsatisfactory use effect of stone engraving machine, and achieve the effect of reducing the cost of consumables, convenient use and keeping clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

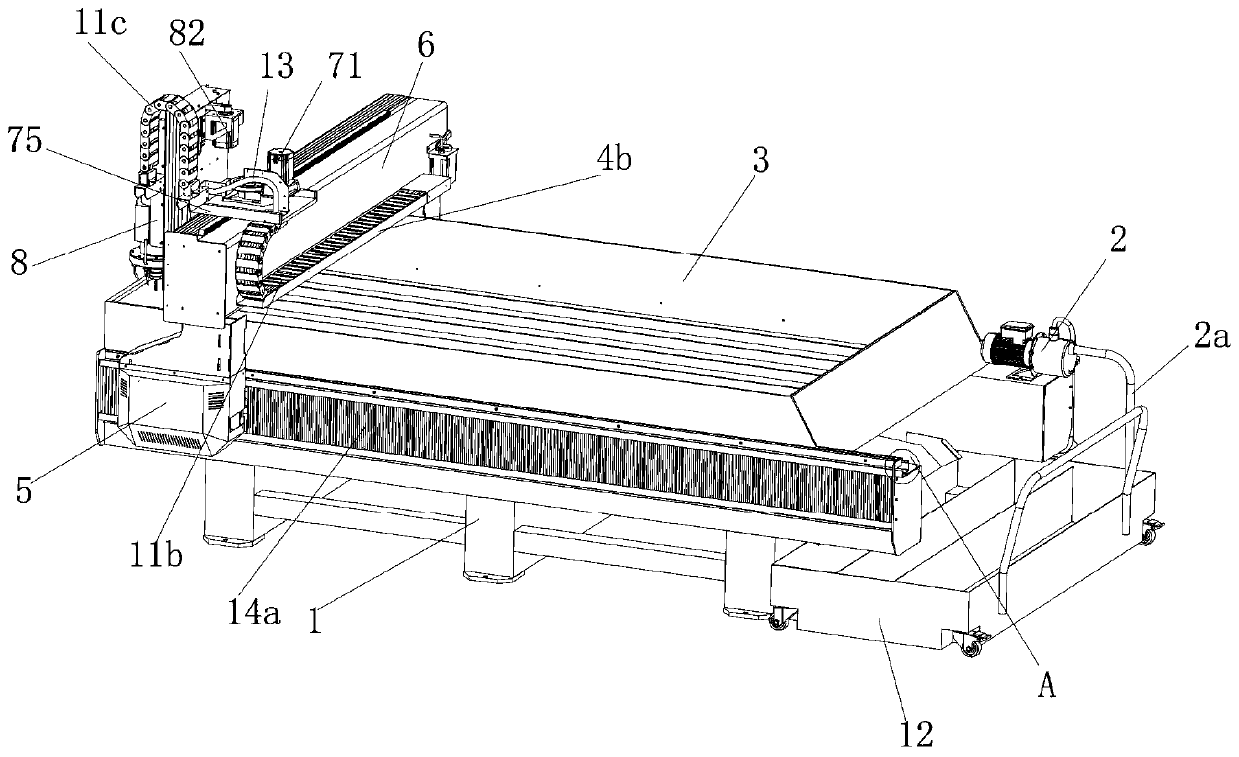

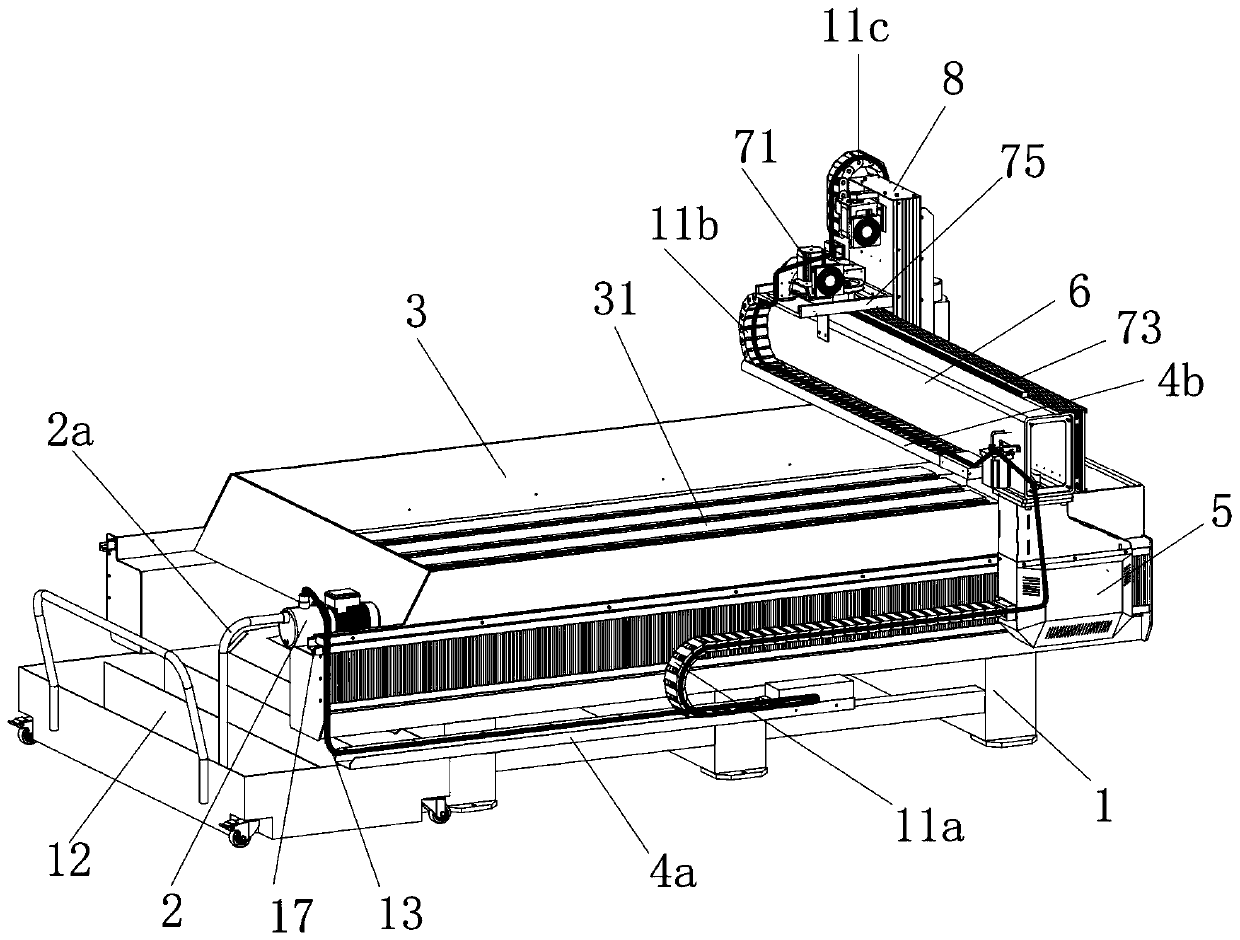

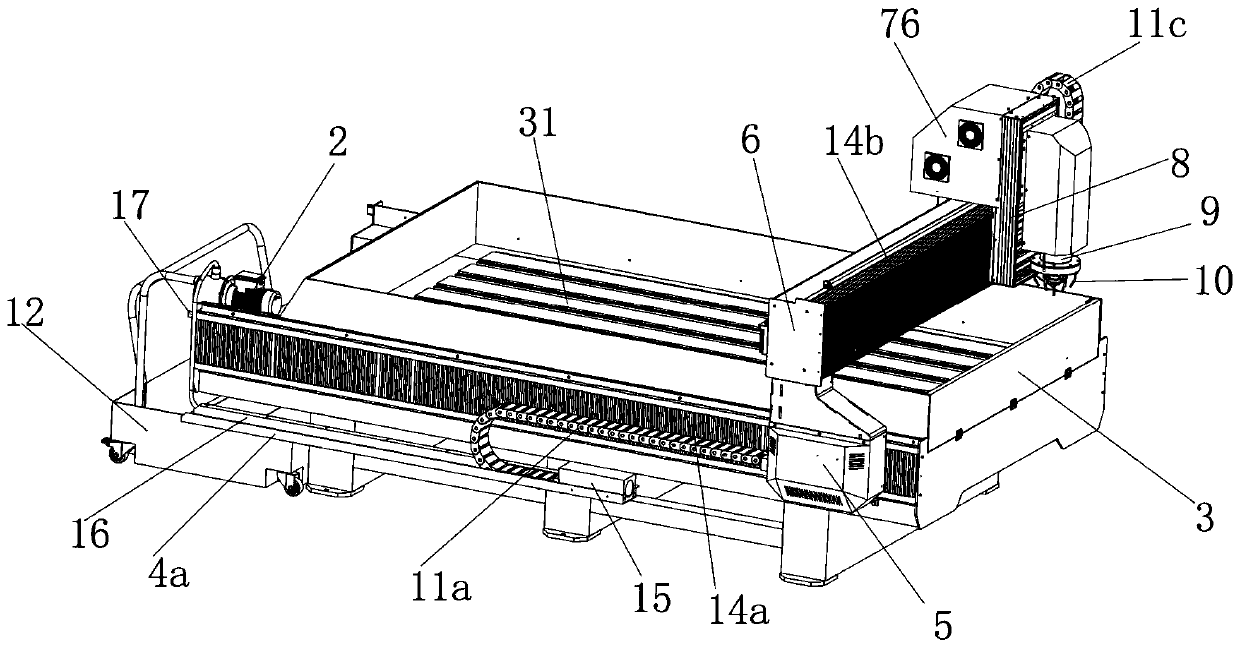

[0030] Depend on Figure 1-15 Given, the present invention comprises base 1, and base 1 top is provided with stone material fixed platform 3, and stone material fixed platform 3 is provided with crossbeam 6 sliding and fixing along its length direction, and crossbeam 6 is provided with along its length direction sliding and fixing. Lifting platform 8, vertically sliding and fixed engraving drill 9 is arranged on the lifting platform 8, and the drill bit of engraving drill 9 is provided with nozzles 10 that are uniformly distributed around the circumference;

[0031] The bottoms of both ends of the beam 6 are fixedly connected with sliding bearings 5, the sliding bearings include support plates 58, the outer walls of both sides of the stone fixed platform 3 are provided with transverse rails 54 arranged along the length d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com