Intermediate-speed grabbing type box filling machine

The technology of one-type case packing machine and grabbing mechanism is applied in the direction of packaging to achieve the effect of easy operation, strong integration function and flexible grabbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the drawings and embodiments.

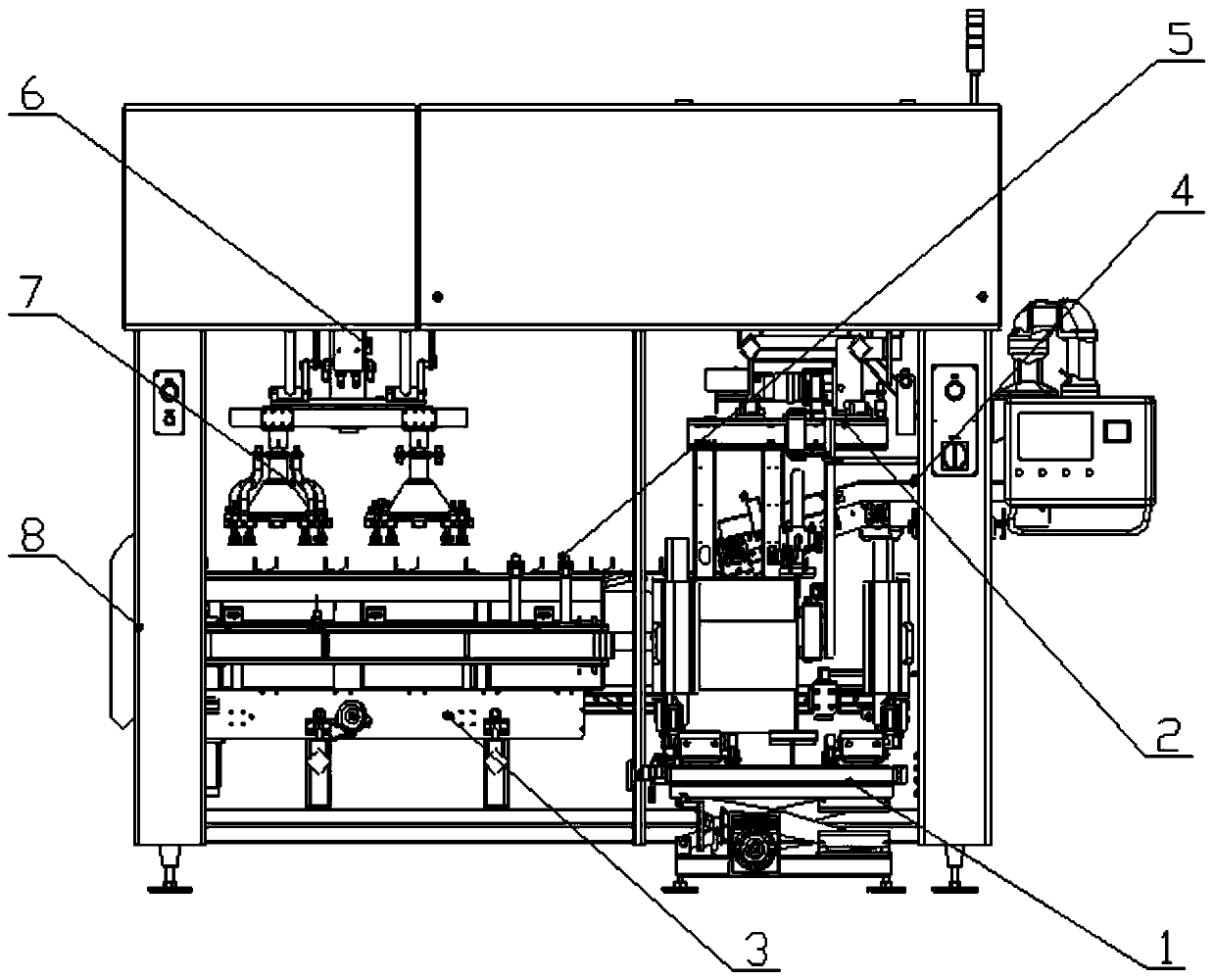

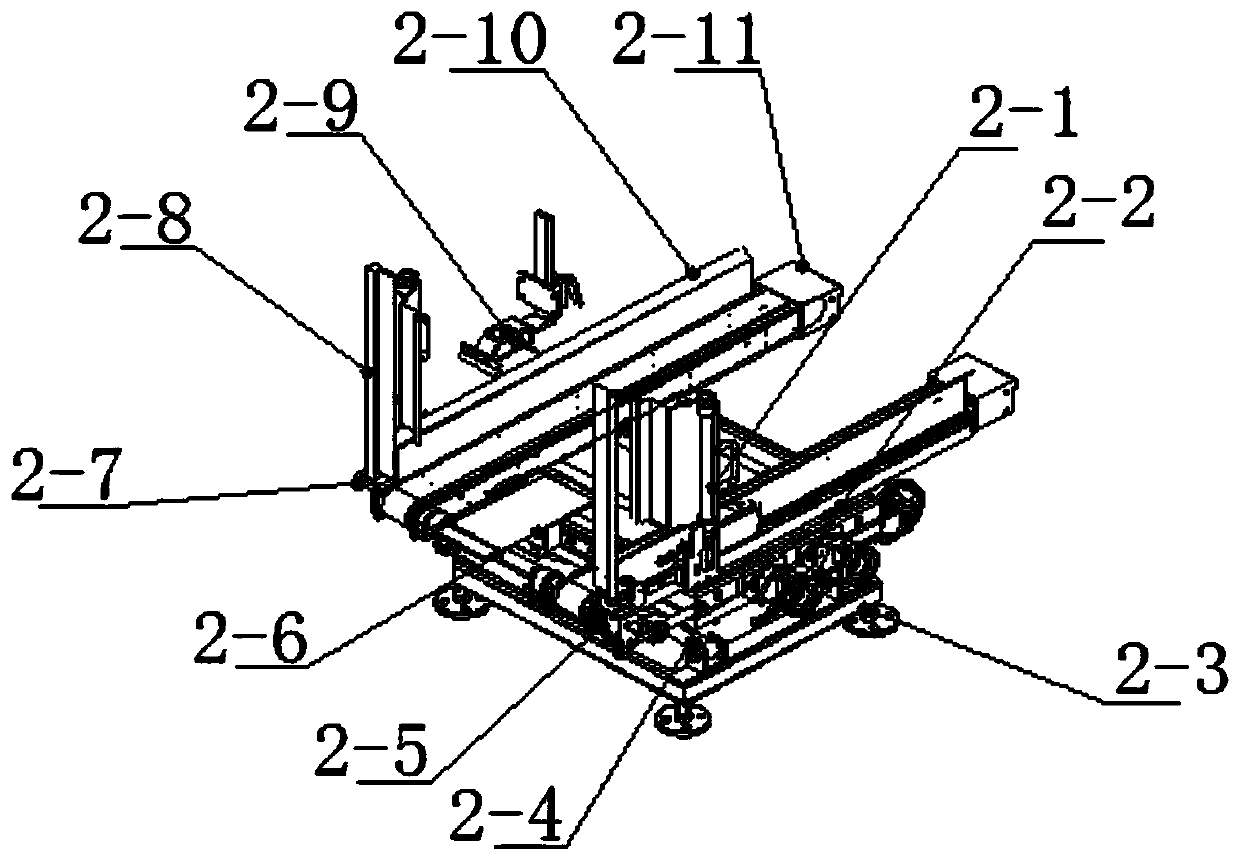

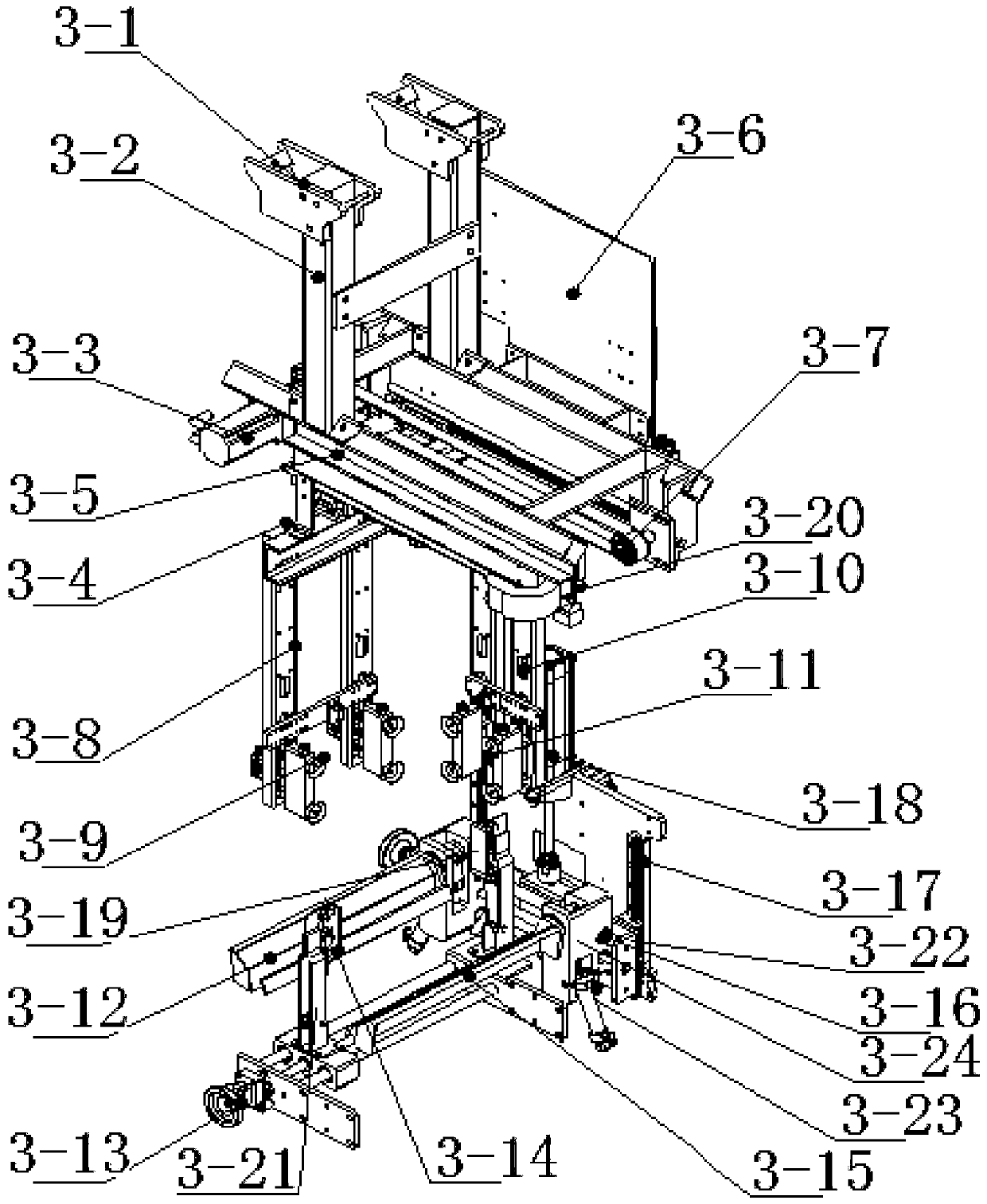

[0045] Reference Figure 1 ~ Figure 7 As shown, the medium-speed grabbing cartoning machine in an embodiment provided by the present invention includes a carton forming device, a material conveying and counting mechanism, a material arrangement double-loop chain, a Delta2 grabbing mechanism, a suction telescopic gripper and frame components , The output end of the material conveying counting mechanism is docked with the input end of the material arrangement double-ring chain, the carton forming device is arranged on one side of the material arrangement double-ring chain, the Delta2 grabbing mechanism is arranged above the material arrangement double-ring chain and the carton forming device, suction type The telescopic gripper is arranged on the Delta 2 grasping mechanism, and the Delta 2 grasping mechanism is arranged on the frame part.

[0046] Further, the material ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap