Vision algorithm based blockage detecting method of mineral belt transferring machine head

A blockage detection, belt conveyor technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problem of easy alarm, mercury or kerosene switch cannot be detected with high precision, durability, sensitivity and reliability are not ideal, etc. problems, to achieve the effect of reducing labor costs, avoiding stagnation of coal production, and high accuracy of detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

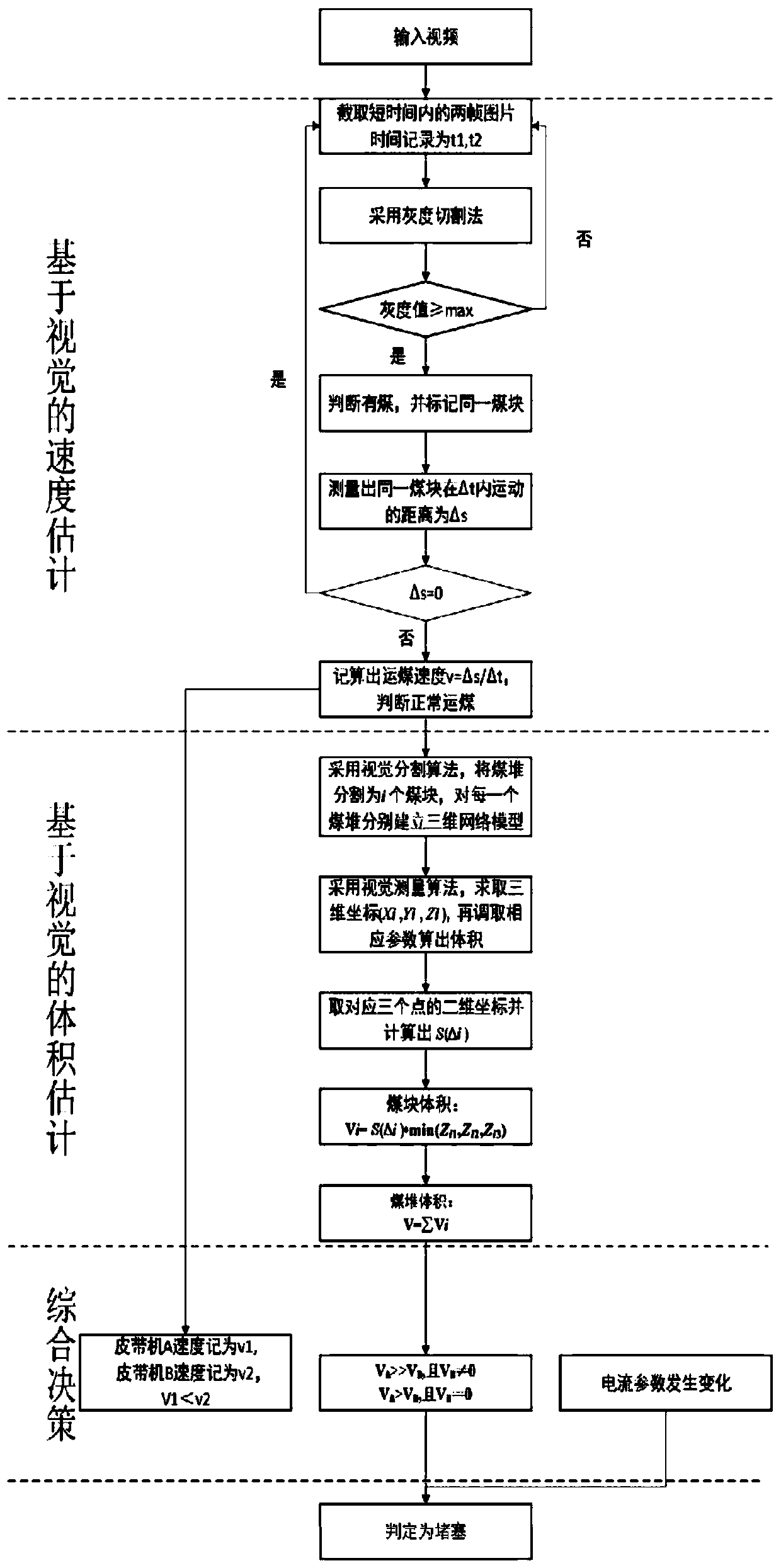

[0030] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

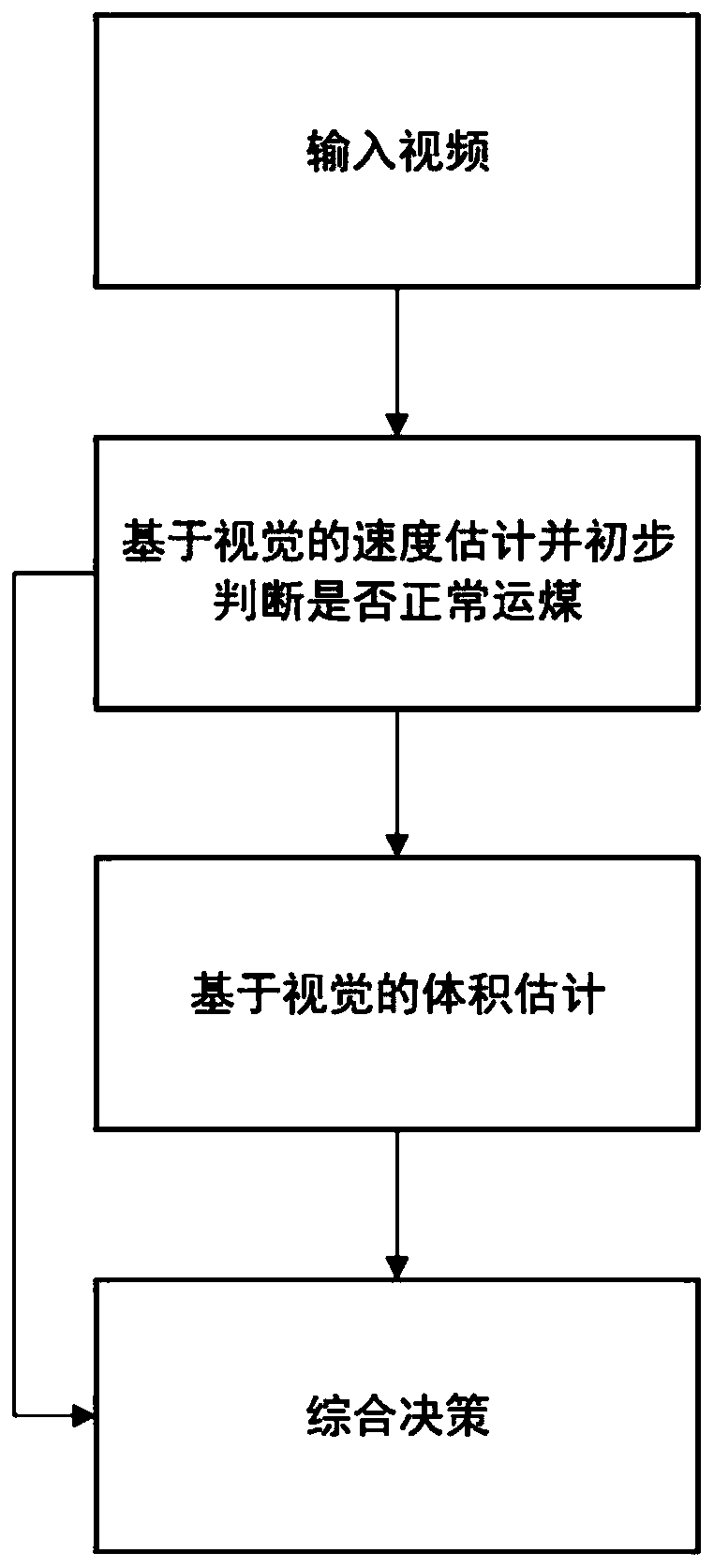

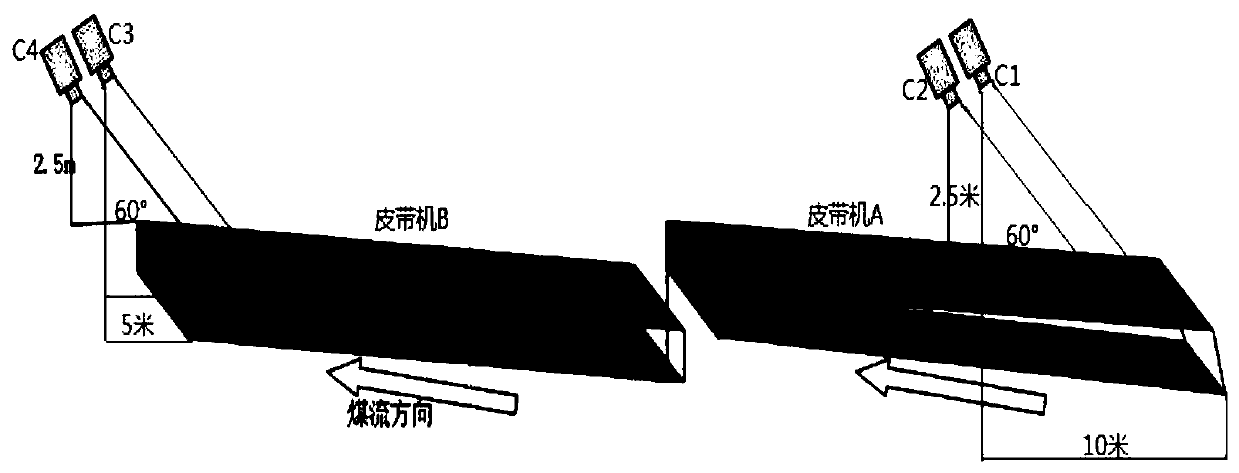

[0031] Such as figure 1 As shown, the coal mine belt transfer machine head blockage detection method based on vision algorithm of the present invention is based on the object tracking algorithm of vision, belt transport speed estimation: in the process of belt conveyor transporting coal, the reflectivity of coal block is obviously higher than that of belt conveyor and The coal block at the end is always at the brightest position of the video, and the coal block area is obtained by the grayscale cutting method based on vision. The received color video is processed and converted into a gray video, and when the gray value is greater than the fixed threshold max, it is determined as a coal block area.

[0032]

[0033] The video speed measurement method is:

[0034] v=Δs / Δt

[0035] Among them, Δs corresponds to the distance in the real world co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com