High-strength low-sulfur high-manganese inoculation gray cast iron material and smelting and pouring process thereof

A grey cast iron and high-strength technology, which is applied in the field of high-strength, low-sulfur and high-manganese inoculated grey cast iron materials and its smelting and pouring process, can solve the problem that the strength of thick and large core parts is difficult to meet the requirements, the graphite shape is not stable, and the strength of grey cast iron is not stable. Low problems, to achieve the effect of eliminating carbides and supercooled structures, improving mechanical properties and machining properties of castings, and improving machining properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

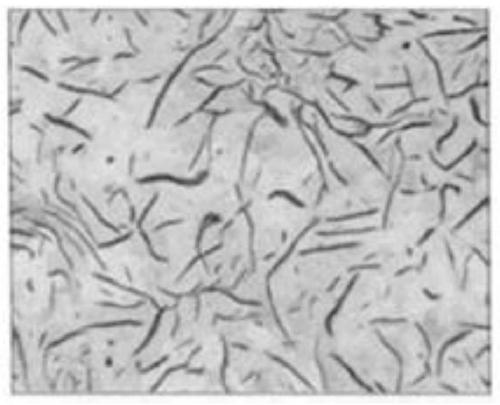

[0038] A high-strength, low-sulfur, high-manganese inoculated gray cast iron material, the composition of which is expressed in weight percent:

[0039] Carbon 3.18%, silicon 1.95%, manganese 0.9%, phosphorus 0.03%, sulfur 0.03%.

[0040] A smelting and pouring process for a high-strength, low-sulfur, high-manganese inoculated gray cast iron material comprises the following steps:

[0041] 1) Add crushed steel, pig iron, furnace charge, and recarburizer into an intermediate frequency induction furnace, and turn on the electric furnace for smelting; the recarburizer is silicon carbide.

[0042] 2) Control the temperature of the electric furnace within the range of 1500°C and continue heating for 10 minutes;

[0043] 3) Obtain molten iron from the electric furnace with a sampling spoon, and detect the content of each element in the molten iron through a metal element analyzer. If the composition is unqualified, keep heating and add missing elements to adjust. If the composition...

Embodiment 2

[0049] A high-strength, low-sulfur, high-manganese inoculated gray cast iron material, the components of which are represented by weight percent: 3.05% carbon, 1.85% silicon, 0.8% manganese, 0.05% phosphorus, and 0.049% sulfur.

[0050] A smelting and pouring process for a high-strength, low-sulfur, high-manganese inoculated gray cast iron material comprises the following steps:

[0051] 1) Add crushed steel, pig iron, furnace charge, and recarburizer into an intermediate frequency induction furnace, and turn on the electric furnace for smelting; the recarburizer is silicon carbide.

[0052] 2) Control the temperature of the electric furnace within the range of 1540°C and continue heating for 8 minutes;

[0053] 3) Obtain molten iron from the electric furnace with a sampling spoon, and detect the content of each element in the molten iron through a metal element analyzer. If the composition is unqualified, keep heating and add missing elements to adjust. If the composition is ...

Embodiment 3

[0058] Embodiment 3: A high-strength, low-sulfur, high-manganese inoculated gray cast iron material, the components of which are represented by weight percent: 3.2% carbon, 2.05% silicon, 1.4% manganese, 0.01% phosphorus, and 0.01% sulfur.

[0059] The components of the gray cast iron material are represented by weight percent: 3.12% carbon, 1.96% silicon, 1.2% manganese, 0.05% phosphorus, and 0.01% sulfur. In the final casting, its components and the weight percentage of each component are: 3.18% carbon, 1.95% silicon, 0.9% manganese, 0.03% phosphorus, and 0.03% sulfur.

[0060] A smelting and pouring process for a high-strength, low-sulfur, high-manganese inoculated gray cast iron material comprises the following steps:

[0061] 1) Add crushed steel, pig iron, furnace charge, and recarburizer into an intermediate frequency induction furnace, and turn on the electric furnace for smelting; the recarburizer is silicon carbide.

[0062] 2) Control the temperature of the electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com