Horizontal splicing and installation structure and installation method of fabricated floor finish surface

An installation structure and prefabricated technology, which is applied to floors, building structures, partial raised floors, etc., can solve the problems of pollution maintenance and low efficiency, and achieve the effect of neat and clean site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

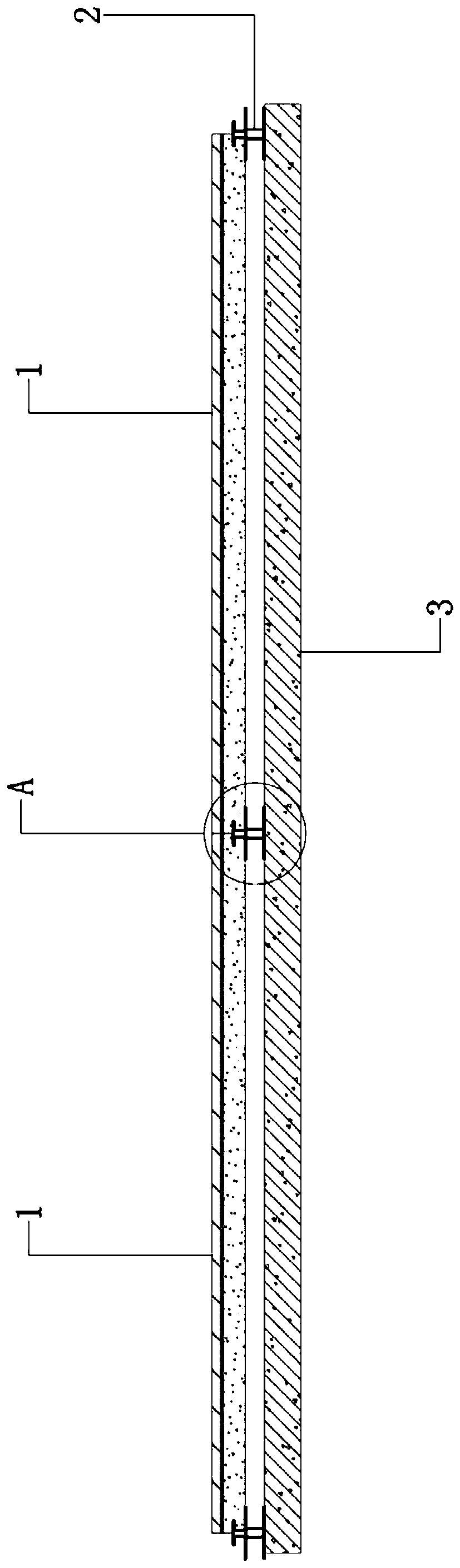

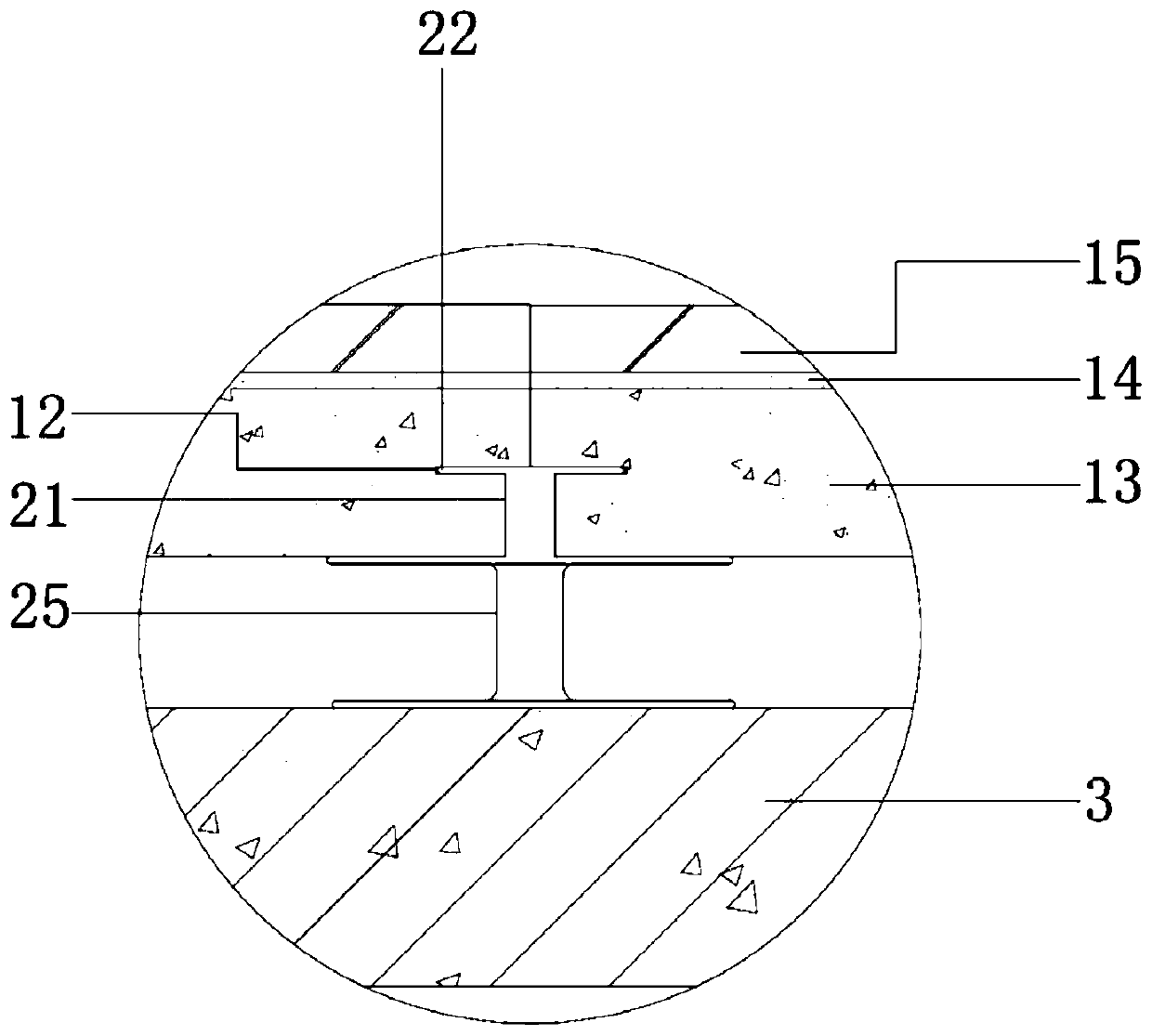

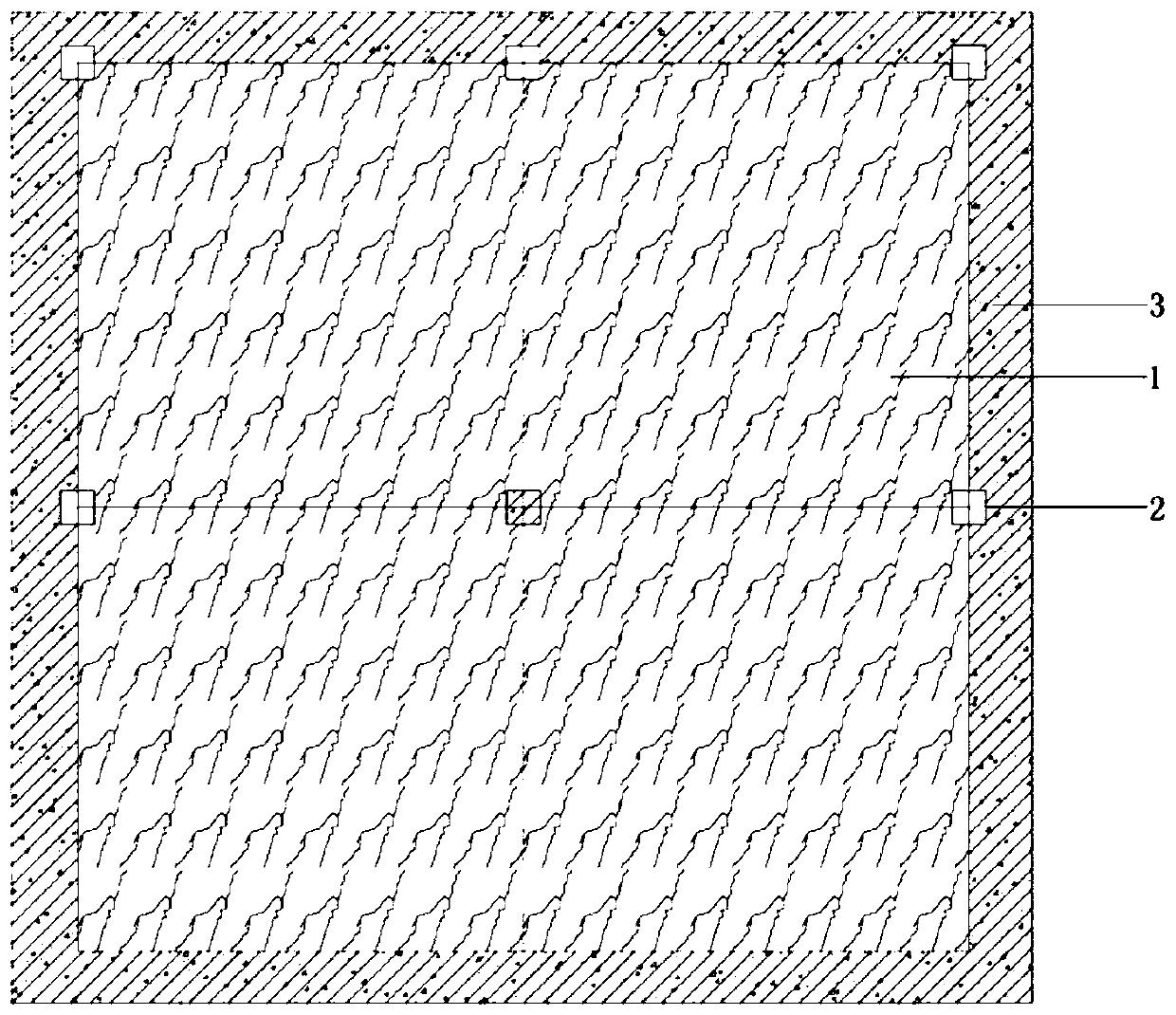

[0037] see Figure 1 to Figure 5 , the figure shows a horizontal splicing installation structure of an assembled floor finish provided by Embodiment 1 of the present invention, in which a plurality of floor finish components 1 and a plurality of bracket components 2 are mainly arranged, and the floor finish components 1 includes the cement board 13 at the bottom (i.e. the base board), the adhesive layer 14 in the middle and the tile layer 15 on the surface (i.e. the decorative panel). The bottom of the bracket part 2 is fixed or placed on the ground base layer 3, and the top of the bracket part 2 is also fixedly provided with a clamping part 21.

[0038] join figure 2 and Figure 4 , the clamping portion 21 is specifically a T-shaped structure, which includes a first support column 211 and a clamping plate 212, the bottom of the first support column 211 is fixedly connected to the bracket component 2, and the top of the first support column 211 is fixedly connected and clam...

Embodiment 2

[0048] see figure 2 and Figure 4, the figure shows a horizontal splicing and installation structure of a prefabricated floor finish provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: The bracket part 2 is an I-shaped bracket, which specifically includes a top plate 23 and a bottom plate 24 parallel to each other. The top plate 23 and the bottom plate 24 are connected by a second support column 25, and the clamping part 21 is fixedly arranged on the top plate 23, and the top plate 23 and base plate 24 are all rectangular plates. Through the setting of the above structure, the support stability of the support part to the floor tiles and the like can be ensured, and can cooperate with the clamping part to form a supporting and clamping integrated component.

Embodiment 3

[0050] see figure 2 and Figure 4 , the figure shows a horizontal splicing and installation structure of a prefabricated floor finish provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: The surface of the top plate 23 is evenly distributed with multiple ribs 231. Taking the rectangular top plate as an example, it is better to set a plurality of ribs that intersect each other, so that when four base plates are spliced together, the corners of the base plates can be just right. Positioning is realized through the convex ribs, making the seams more orderly and beautiful.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap