Shimming coil optimization design and manufacturing method and structure thereof

A shimming coil and optimized design technology, which is applied in coil manufacturing, coils, steering induction equipment, etc., can solve the problems of coil magnetic field uniformity requirements and coil volume constraints that are difficult to meet at the same time, and the volume of shimming coils is large, so as to reduce the Effect of stray magnetic field and guarantee of magnetic field accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

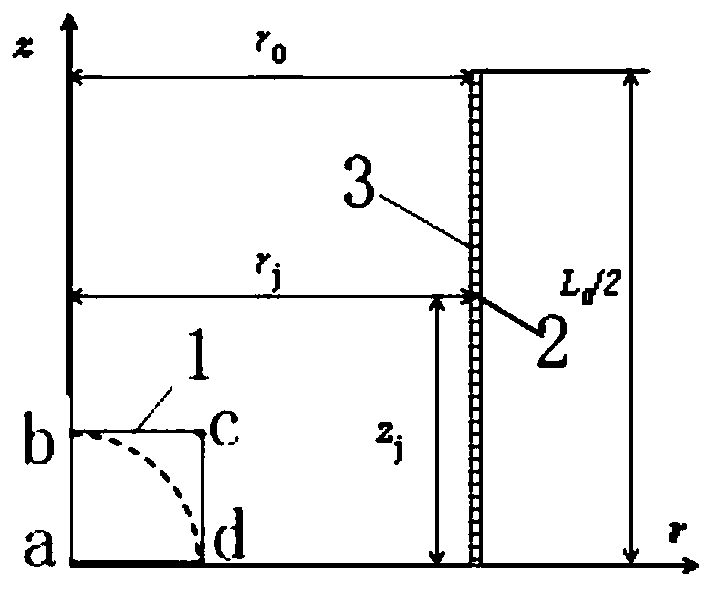

[0050] Example 1, as figure 1 , figure 2 shown;

[0051] The optimal design of the shim coil includes the following steps:

[0052] S1. Determine the parameters to be optimized related to the uniformity δ of the magnetic field of the coil and the size of the volume. The parameter to be optimized is the radial size r of the coil 0 , Axial dimension L 0 , the wire diameter D, the number of coil turns m, and the state variable e that characterizes the existence of the energized winding j;

[0053] S2. Determine the optimization process, establish an optimization model, use the optimization model to obtain the optimal solution that satisfies the constraints, and determine r 0 , L 0 , D, m and e values;

[0054] S3. According to r in the optimal solution 0 , L 0 , D, m and e, design and manufacture the shim coil with the smallest volume that satisfies the constraints of magnetic field amplitude and uniformity δ.

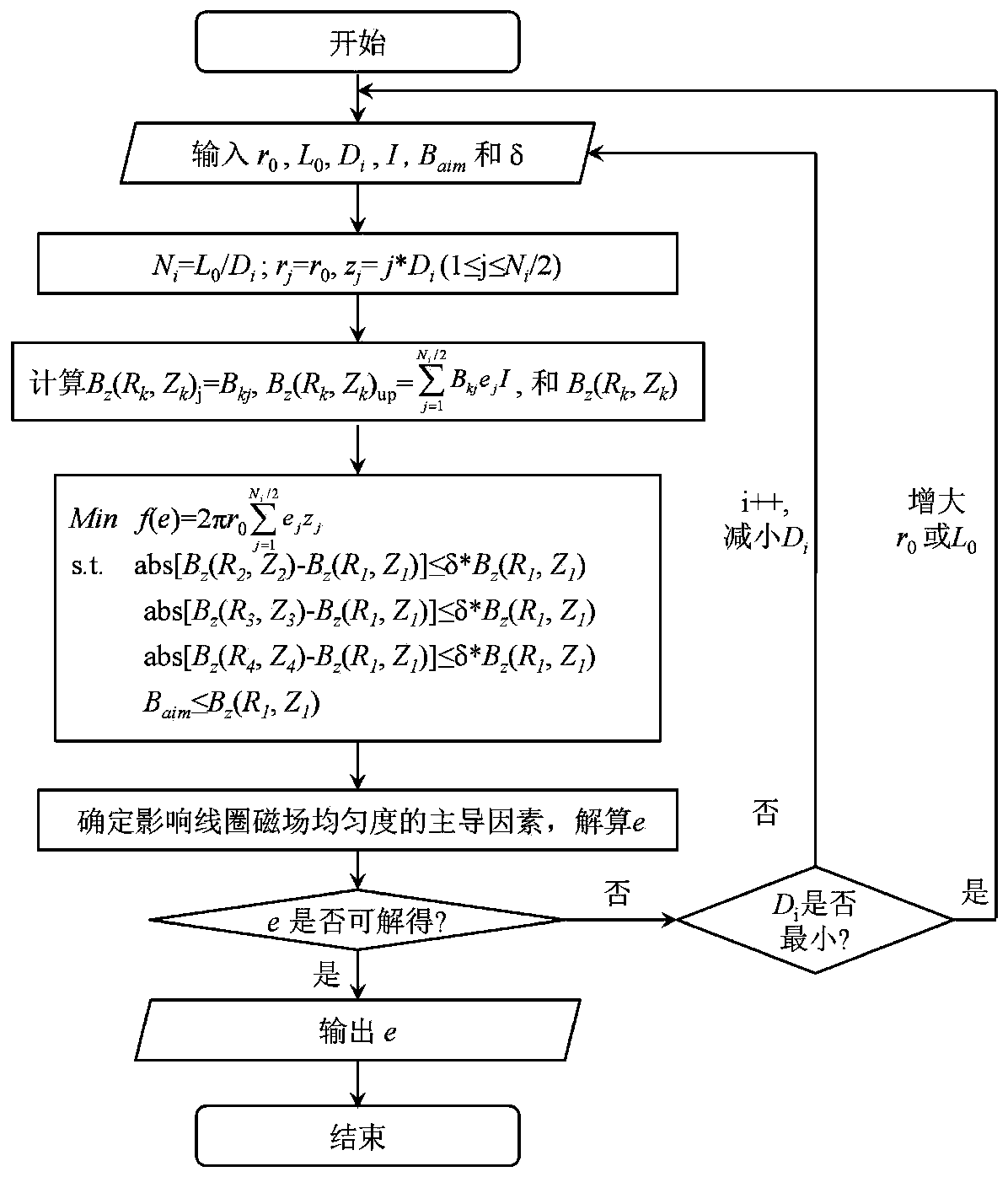

[0055] The following steps are included in S2:

[0056] S...

Embodiment 2

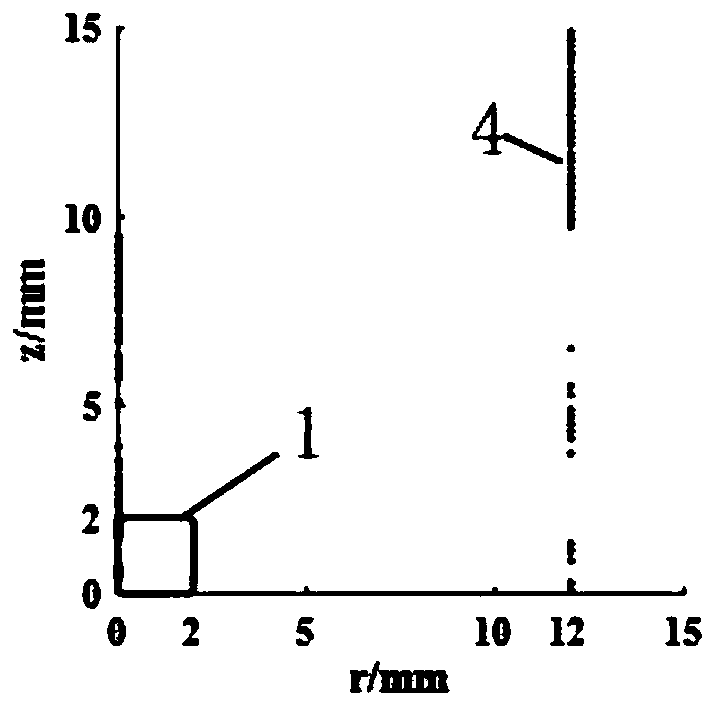

[0064] Example 2, figure 1 , figure 2 , image 3 , Figure 4 shown,

[0065] According to the overall design layout of the NMRG, the radial and axial dimensions r of the initial feasible current-carrying domain 3 are preliminarily determined 0 and L 0 They are 12mm and 30mm respectively, and the target shimming area 1 is a cylindrical area with a diameter of 4mm in the center of the coil and a length of 4mm. Determine the target shimming area 1 magnetic field B z The minimum amplitude B required to be reached aim is 50 amplitude, the coil current I is 100mA, and the magnetic field uniformity δ of the target shimming area 1 is 1 / 10 5 , the initial wire diameter D of the coil i is 1mm, the number of turns and wire diameter of the optimized coil are 82 turns and 0.2mm, respectively. The number of turns distribution of the optimized cylindrical coil (1 / 4 axisymmetric area) is as follows image 3 shown. The axial magnetic field uniformity δ of the optimized cylindrical c...

Embodiment 3

[0066] Example 3, as Figure 5 , Image 6 , Figure 7 shown,

[0067] A method for making a shim coil, comprising the following steps;

[0068] S1, according to r in the optimal solution 0 and L 0 The value of , determines the length and width of the flexible substrate 7;

[0069] S2. According to the value of D in the optimal solution, select the energized wire 9 of the corresponding diameter;

[0070] S3, install the energized wire 9 on the flexible substrate 7, and determine the number of turns and the installation position of the energized wire 9 on the substrate 7 according to the values of m and e in the optimal solution;

[0071] S4. The input wire 11 is communicated with the input end of the first row of energized wires 9, a plurality of connection wires are arranged in the middle of the substrate 7, and the plurality of connection wires are arranged in a row, and the output end of the nth row of energized wires 9 is connected to the The input end of the energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com