Metallographic corrosive agent for advanced high-strength steel residual austenite dyeing and using method of metallographic corrosive agent

A technology of residual austenite and etchant, applied in metallographic etchant for advanced high-strength steel residual austenite staining and its application field, can solve the problem of small contrast difference between residual austenite and martensite and the stability of etchant Insufficient, unable to effectively distinguish and other problems, to achieve the effect of good stability, convenient configuration, and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0044] Table 1 lists the ratio of each component of the metallographic etchant of Examples 1-6.

[0045] Table 1.

[0046]

[0047] Table 2 lists the mass percentage proportions of metallographic samples corroded by the metallographic etchant of Examples 1-6.

[0048] Table 2.

[0049]

[0050] The using method of the metallographic etchant of embodiment 1-6 adopts the following steps:

[0051] The metallographic sample in Table 2 is polished, and the metallographic sample obtained after polishing is immersed in the metallographic etchant listed in Table 1 for 5-20 seconds, then the surface of the metallographic sample is cleaned and dried, and the surface of the metallographic sample is examined under a color microscope. Observation.

[0052] It should be noted that, in some other embodiments, when cleaning the surface of the metallographic sample, it is first cleaned with distilled water, and then cleaned with absolute alcohol.

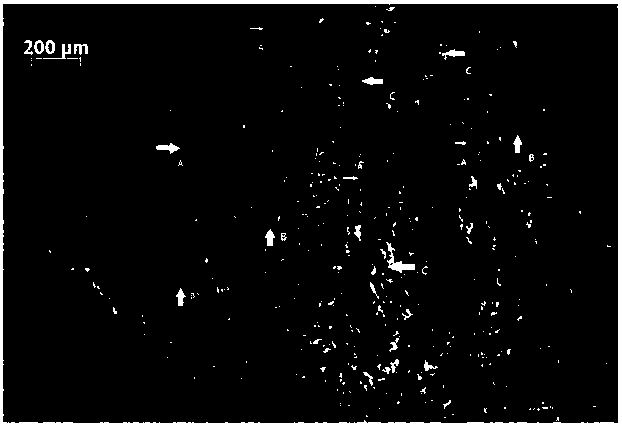

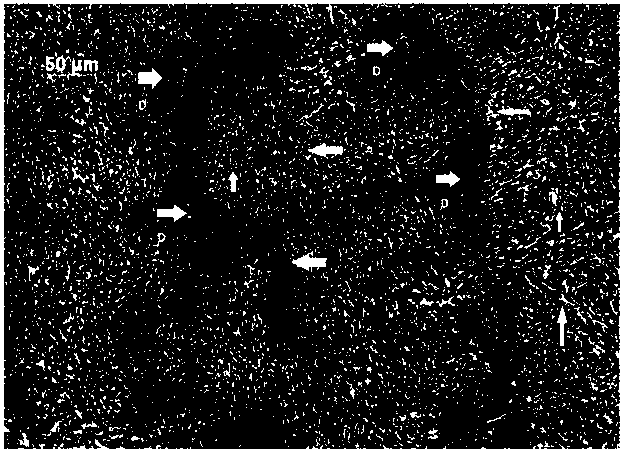

[0053] See the results observed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com