In-situ sample rod for transmission electron microscopy

An electron microscope and sample rod technology, applied in circuits, discharge tubes, electrical components, etc., can solve problems such as inapplicability, inability to achieve accurate temperature control in low temperature areas, and inability to achieve accurate temperature control in full temperature areas, and achieve a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

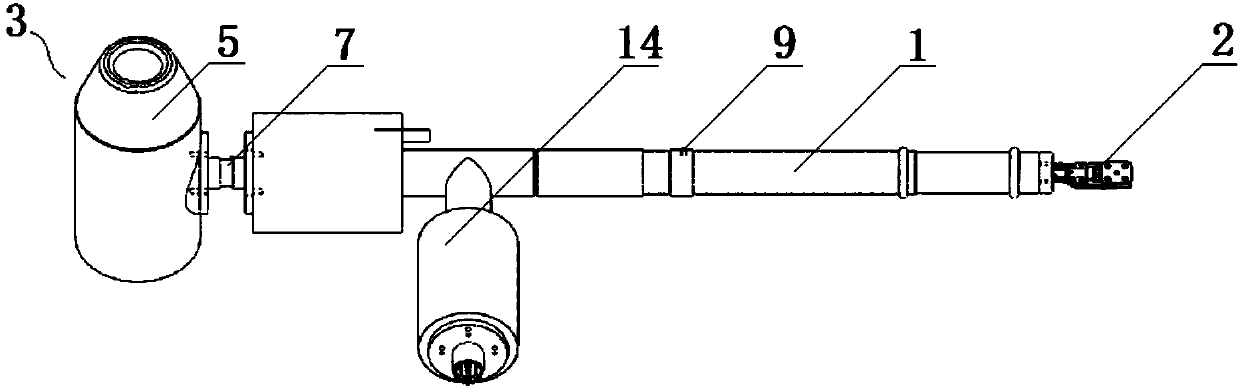

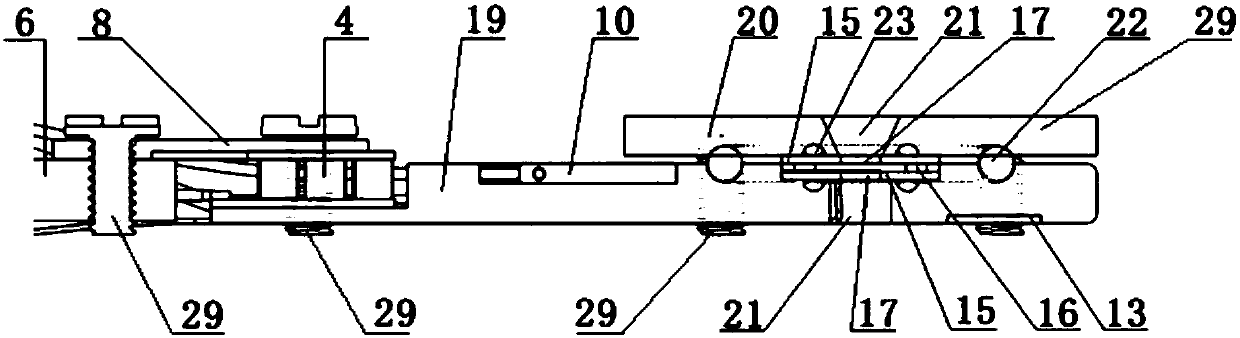

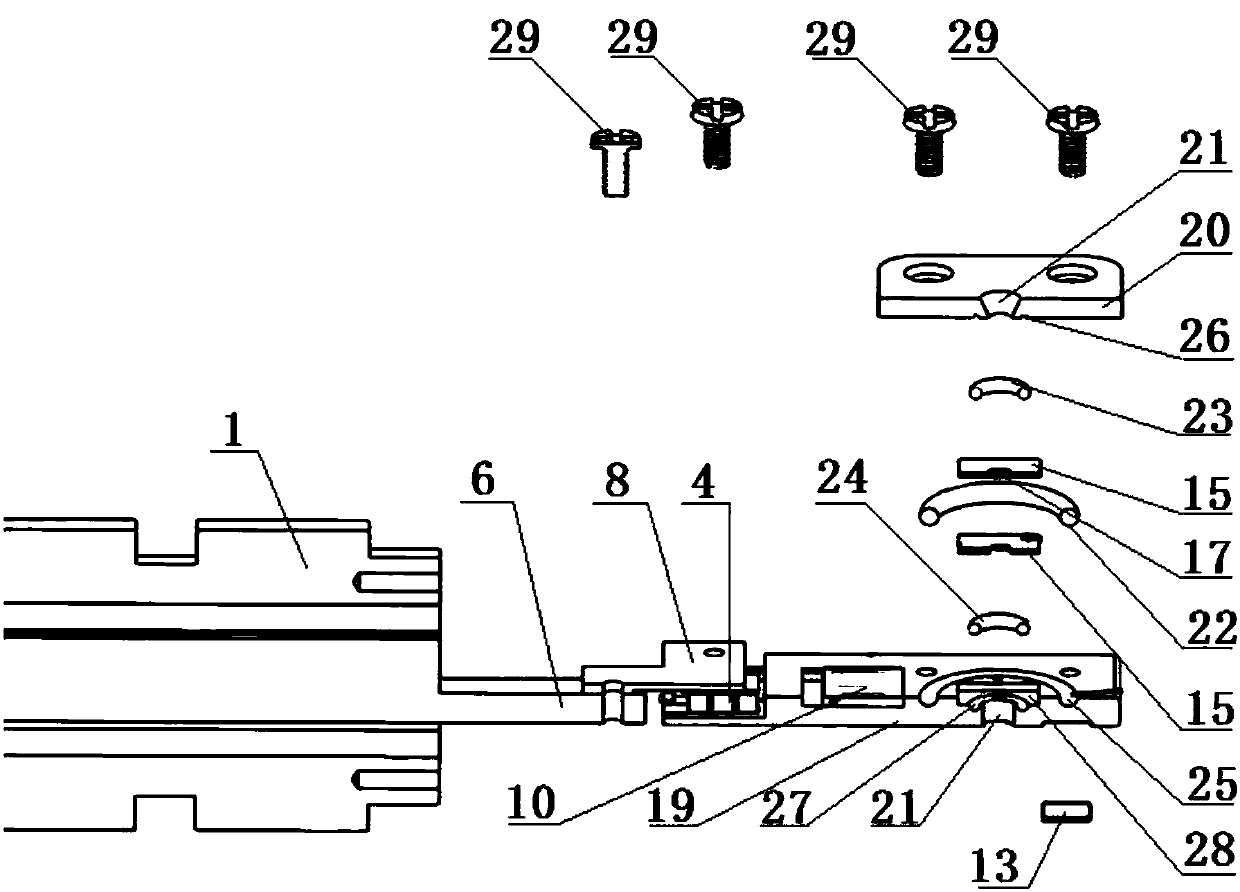

[0035] refer to figure 1 , the present embodiment provides an in-situ sample rod for a transmission electron microscope (hereinafter referred to as the sample rod). The sample rod includes a sample rod shaft 1, a sealed test chamber 2, a passive refrigerator 3, an active refrigerator 4, a temperature detector and a temperature controller.

[0036] Wherein, the sample rod shaft 1 is a revolving body with a circular cross section, which itself is composed of a plurality of rod segments connected in series. Positioning pins 9 are provided on the outer peripheral surface of the sample rod shaft 1, so that the sample rod can be positioned by the positioning pins 9 after being inserted into the transmission electron microscope so that it can rotate ±30° around its o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com