System and method for tracing a product item

A product and project technology, applied in the system field of product projects, which can solve problems such as inaccurate tracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

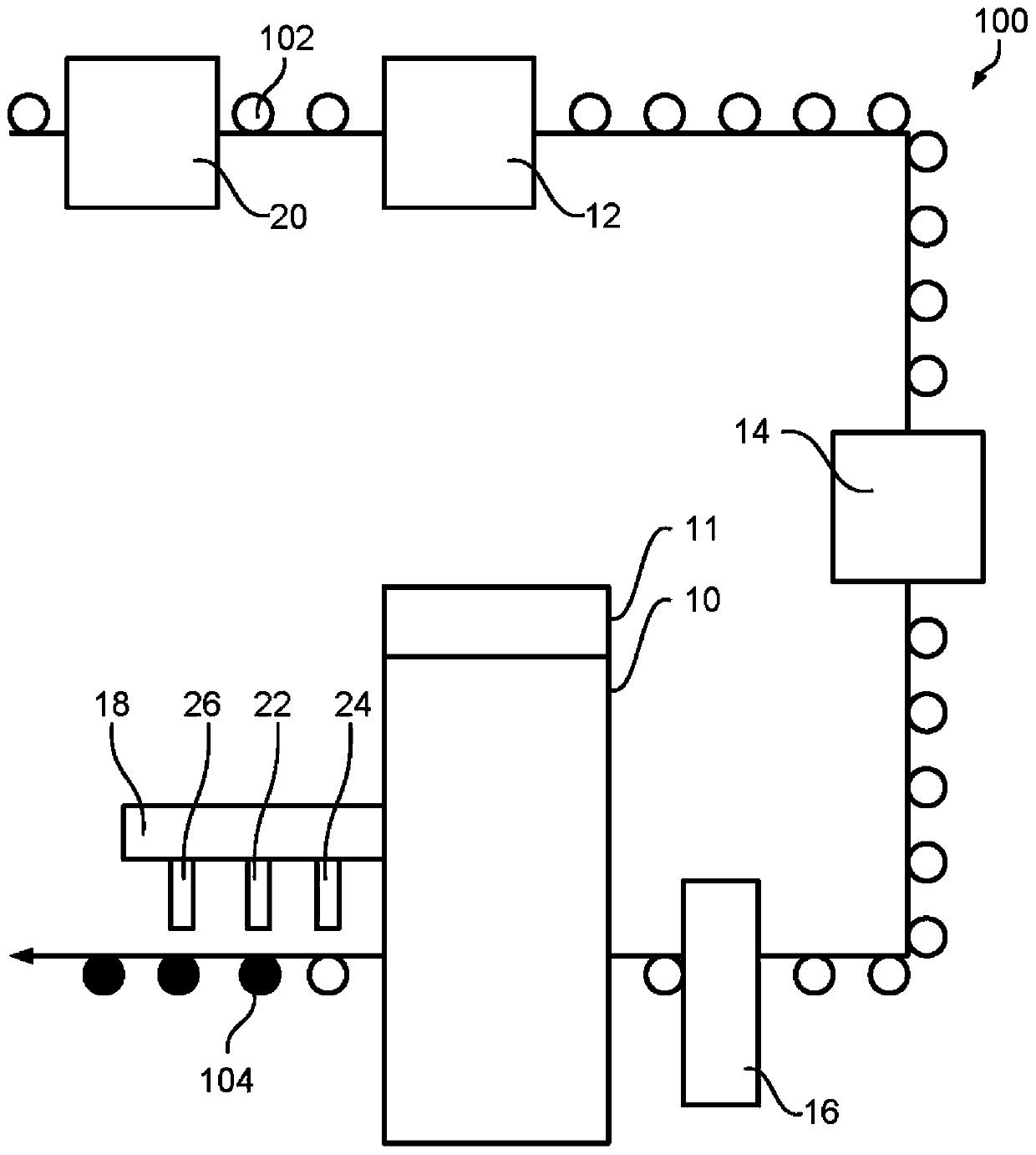

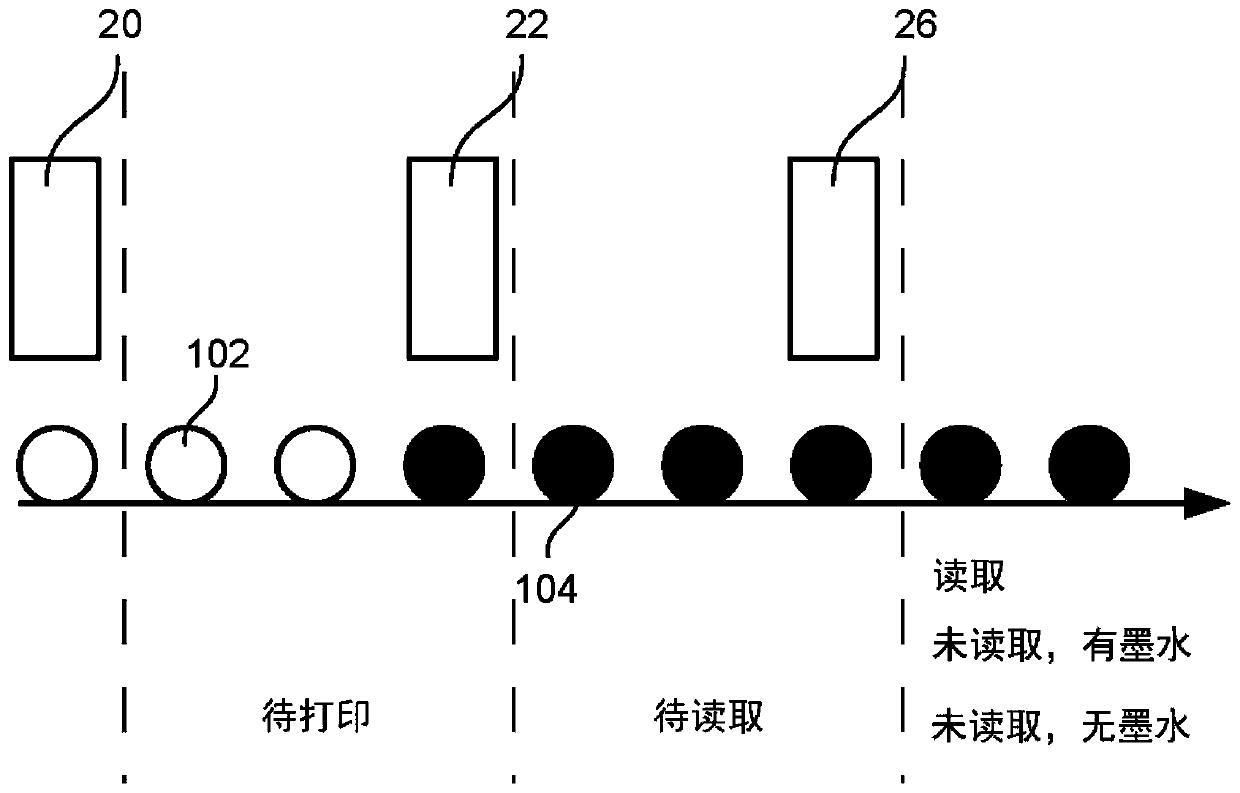

[0022] figure 1 A production line 100 comprising a control unit 10 and a time stamp counter 11 is shown. In this embodiment, the control unit 10 is a programmable logic controller (PLC) configured to receive product signals related to the product items 102, 104 from the peripheral devices 12, 14, 16, 18, 20, 22, 24, 26. ). exist figure 1 In the illustrated embodiment, the peripherals are a fill counter 12 , a brand identification system 14 , a mark static counter 16 , and a beam 18 equipped with a print head 22 , a movement count sensor 24 and a quality camera 26 .

[0023] The control unit 10 at least partially manages or at least partially controls all devices in the production line. It sends trigger signals to printers and cameras in particular.

[0024] The counting sensor 20 initially identifies the presence of a particular product item 102 on the production line and sends information related to the identification of the product item 102 to the control unit 10, where ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com