Centralized control system of adhesive tape machines

A centralized control system and belt conveyor technology, applied in conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problem that the mine belt conveyor control system cannot be applied to large equipment sites, high construction and operating costs, and poor operation stability. and other problems, to achieve the effect of reducing fault processing time, low operating cost and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

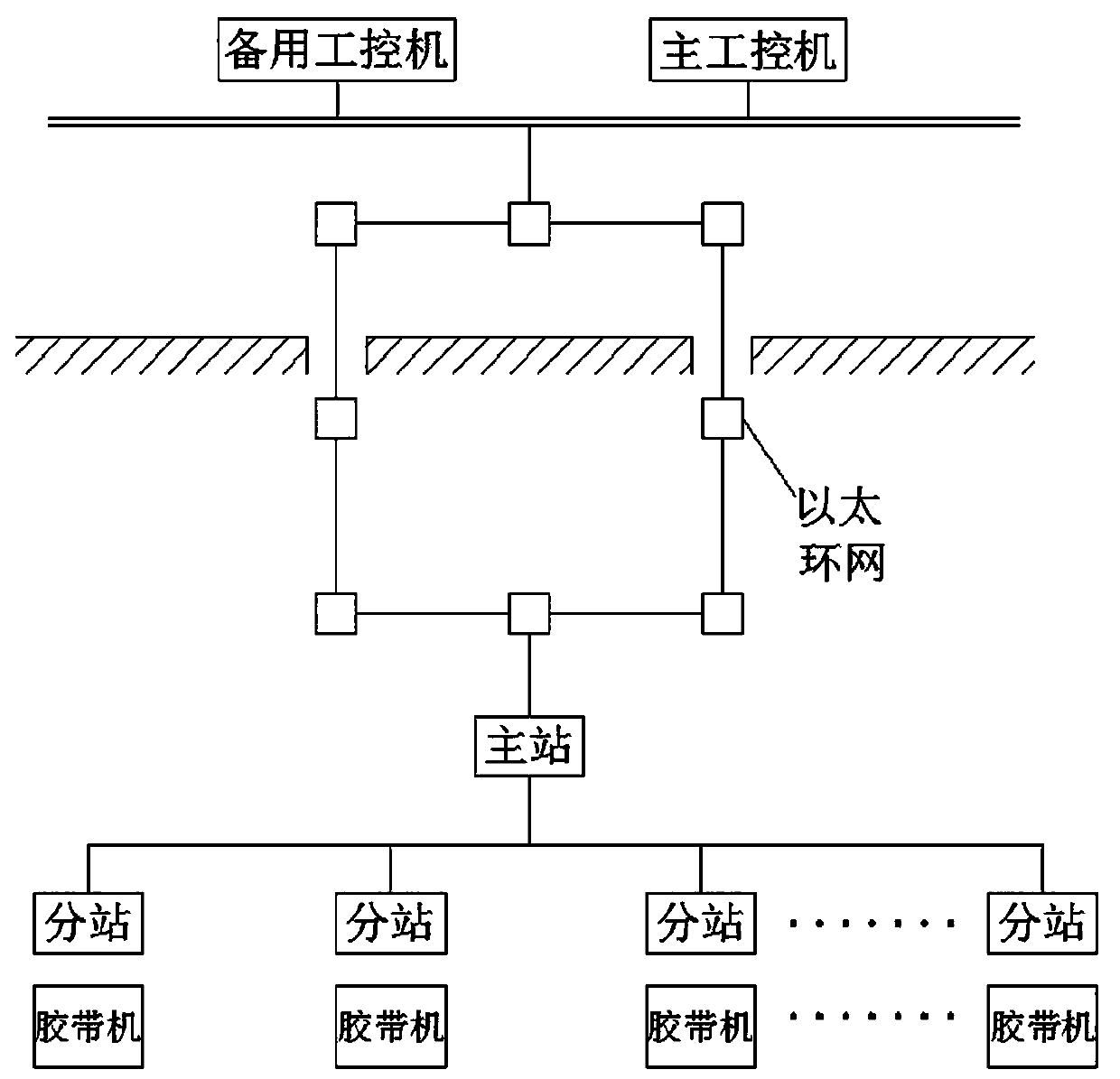

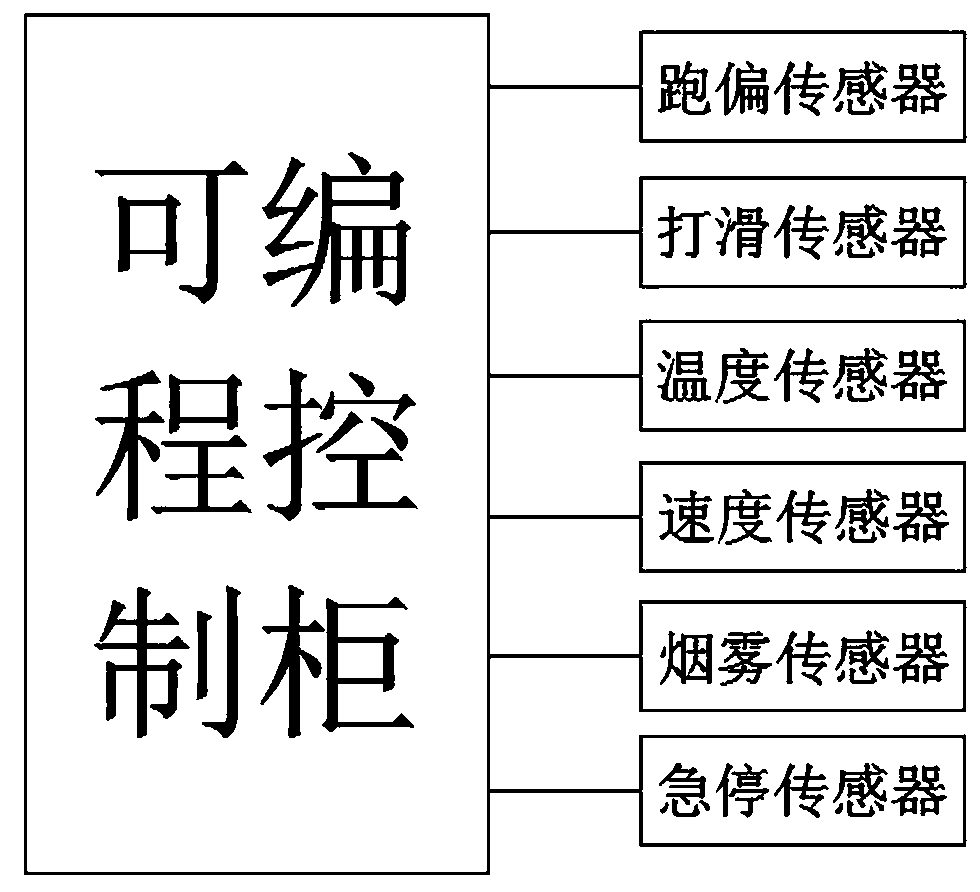

[0013] A centralized control system for tape conveyors, including a central control room on the ground and several tape conveyors installed under the mine. The central control room is equipped with a main industrial computer for remote centralized control, a backup industrial computer and a UPS backup power supply. A printer is connected, and the main industrial computer and the standby industrial computer are connected to the main station installed in the underground through the Ethernet ring network. The main station is connected to substations distributed next to each tape machine, and each substation is equipped with A programmable control cabinet for local control of the tape machine, each of the tape machines is equipped with a deviation sensor, a slip sensor, a temperature sensor, a speed sensor, a smoke sensor and an emergency stop sensor, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com