A conveyor wireless accumulation drive control system and method

A drive control and conveyor technology, applied in the direction of conveyor objects, transportation and packaging, electrical testing/monitoring, etc., can solve the problems of high price of logistics equipment, high labor and material costs, cumbersome on-site wiring, etc., and achieve network increase and decrease nodes. Easy, improve the conveying efficiency, the effect of short debugging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The terminology used herein is for the purpose of describing particular embodiments only and is not intended to be limiting of the invention. Unless otherwise defined, all terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs. It will be further understood that commonly used terms should be interpreted to have a meaning consistent with their meaning in the relevant art and this disclosure. This disclosure is to be considered as an example of the invention and is not intended to limit the invention to the particular embodiments.

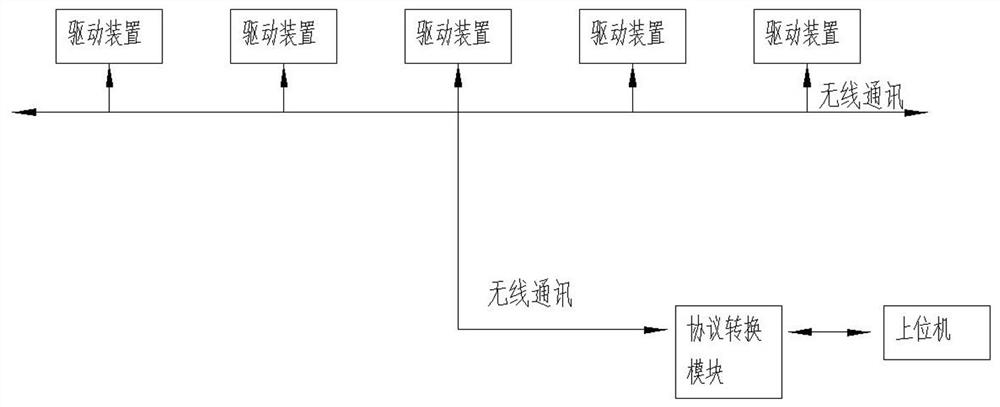

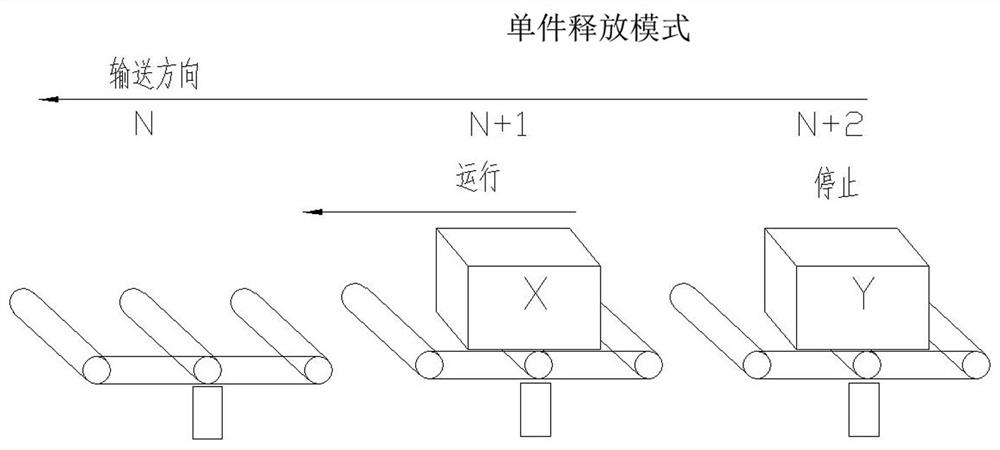

[0054] A wireless accumulation drive control system for an accumulation logistics transmission line of a conveyor. The logistics transmission line is divided into a plurality of stations sequentially along the material conveying direction. Each station includes a motor-driven electric roller and multiple slave rollers that can rotate under the drive of the movable rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com