Dirt discharge structure on tooth rake type bar screen machine

A technology of decontamination machine and grille, which is applied in the fields of water/sludge/sewage treatment, water/sewage treatment, chemical instruments and methods, etc. It can solve the problem that if there is sewage, floating and suspended matter need to be reprocessed through other equipment. In addition to sewage treatment, sewage will flow to the grille decontamination machine and other problems to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

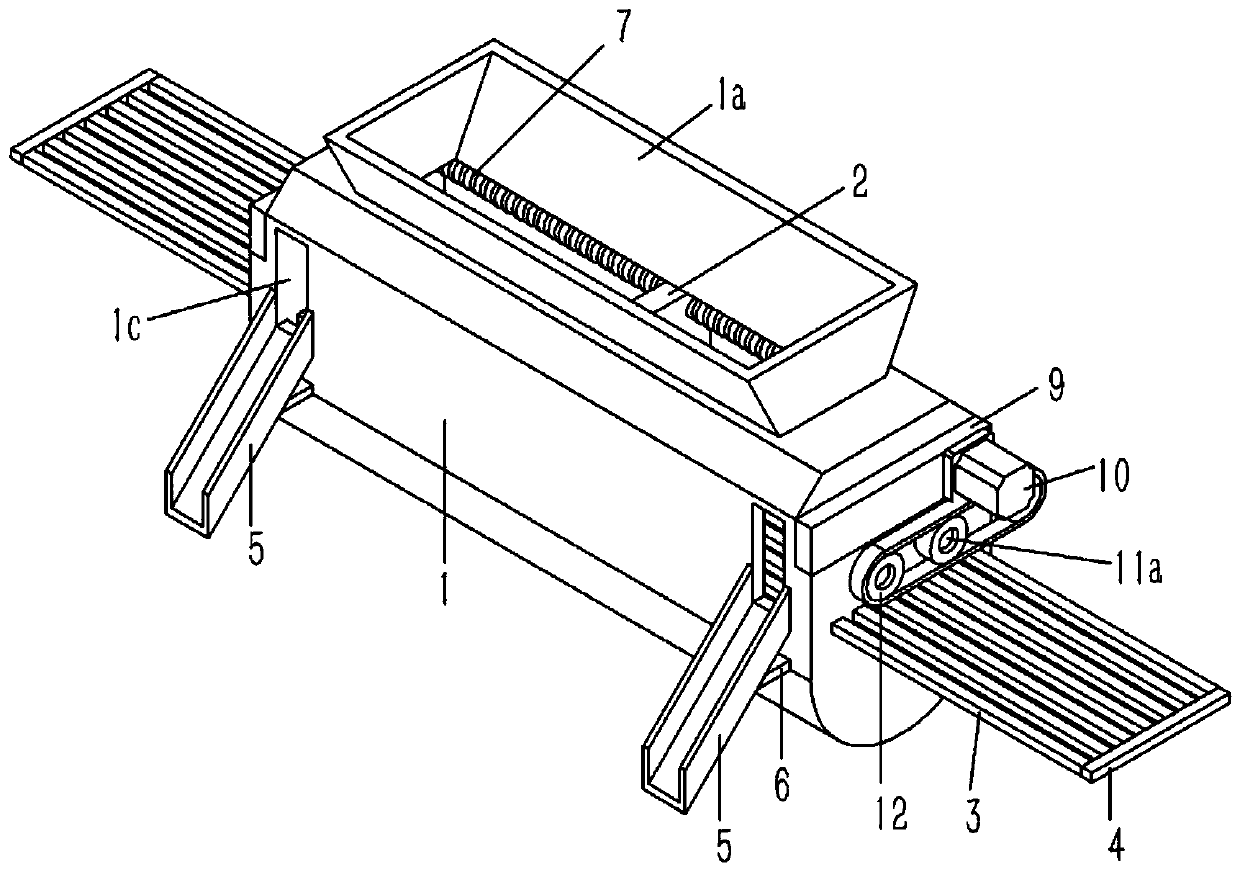

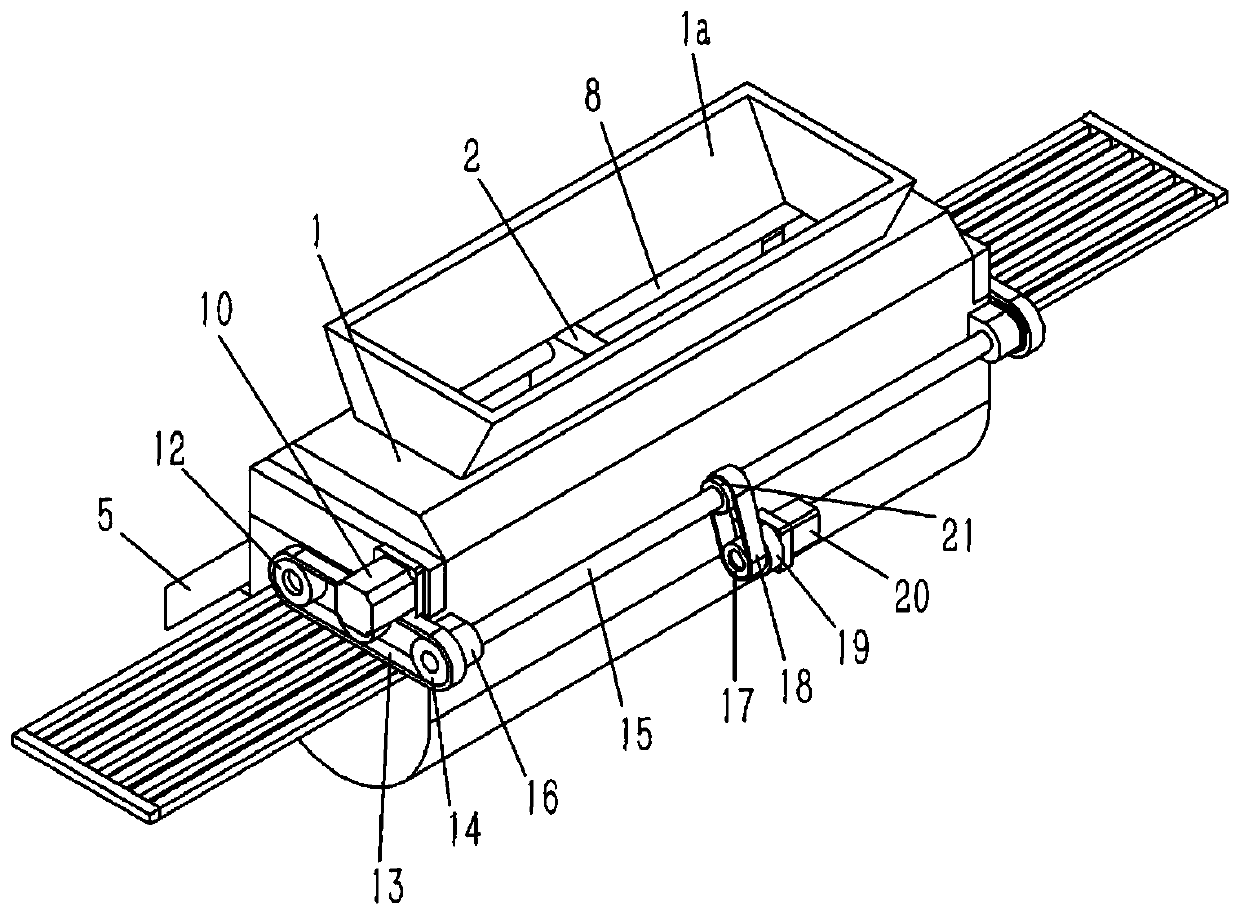

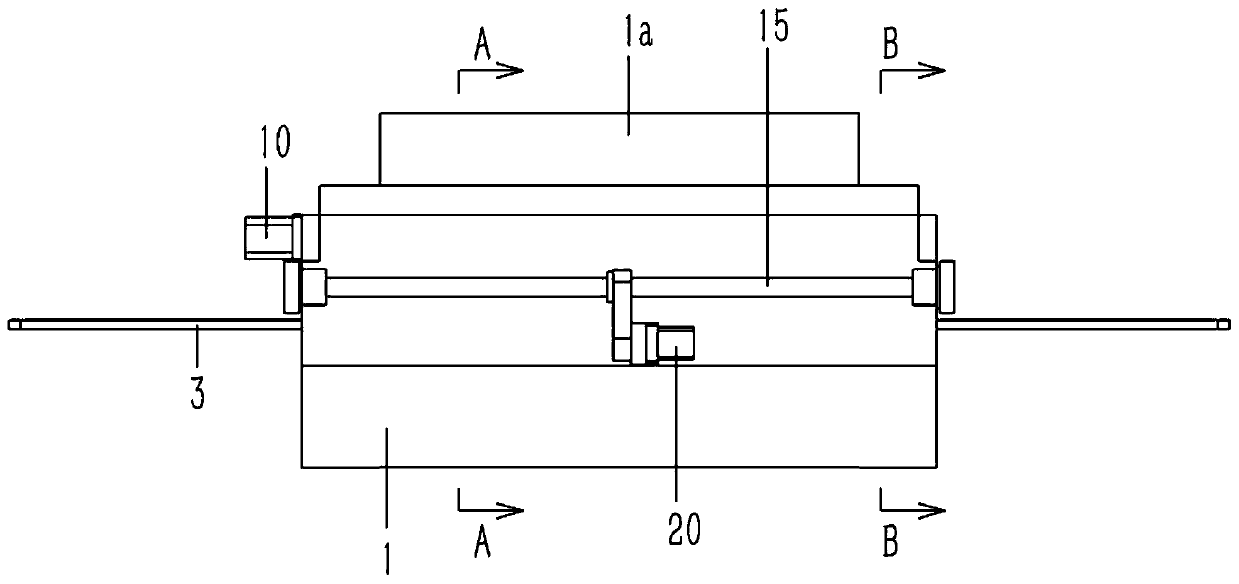

[0021] Example: see Figures 1 to 5 As described above, a dirt discharge structure on a rake-type grille decontamination machine includes a horizontal waste treatment box 1, the top of the waste treatment box 1 is formed with a conical feeding hopper 1a, and the bottom of the waste treatment box 1 The end is formed with a horizontal drainage groove 1b. The waste disposal box 1 is provided with a vertical extruding plate 2. The lower end of the extruding plate 2 is plugged and fixed with several horizontal retaining rods 3. The two ends of the retaining rod 3 The end passes through the left and right sides of the waste treatment box 1 and is fixedly connected to the limit rod 4; the front side of the upper end of the extrusion plate 2 is screwed with a horizontal lead screw 7, and the two ends of the lead screw 7 are inserted into the waste treatment The left and right side walls of the box 1 are against the limit baffle 9, and the limit baffle 9 is fixed on the left and right ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap