High and cold frozen soil area concrete pile foundation

A technology for concrete piles and permafrost areas, applied in sheet pile walls, soil protection, infrastructure engineering and other directions, can solve the problems of reducing the strength and durability of concrete structures, affecting the overall performance of concrete structures, and affecting the stability of tower foundations. , to achieve the effect of reducing heat, significant social and economic benefits and environmental protection significance, and improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

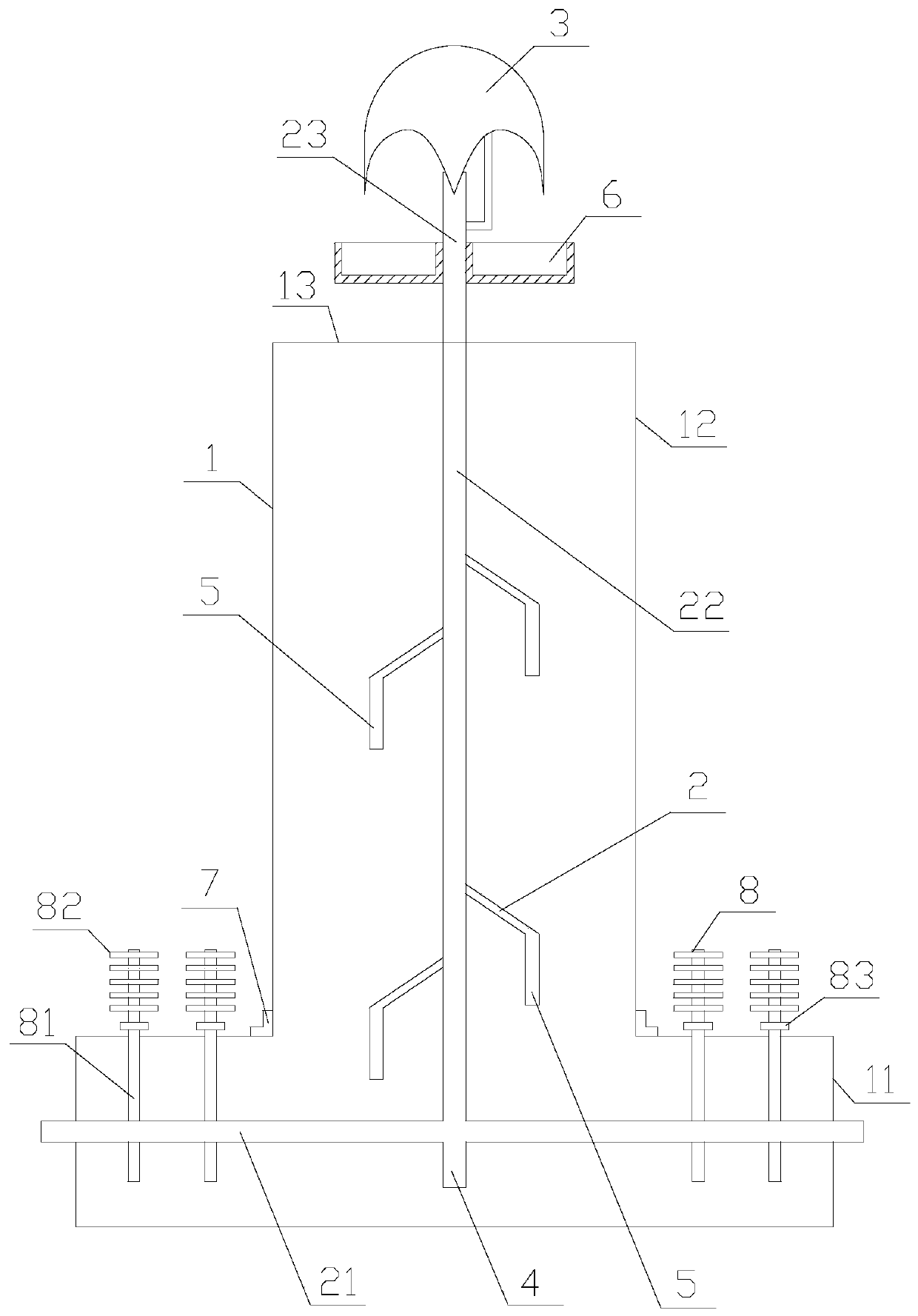

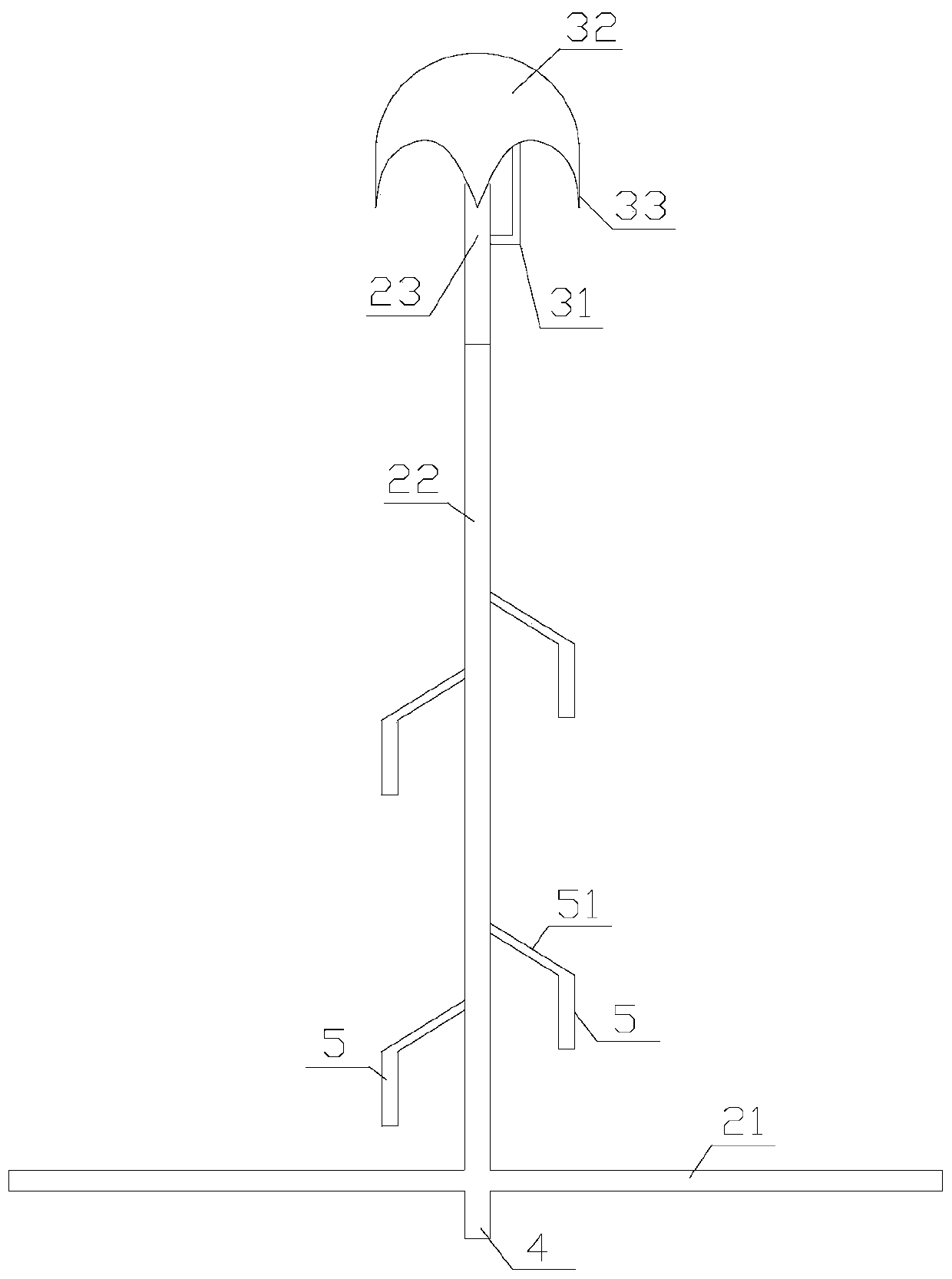

[0034] Such as figure 1 , 2As shown, a concrete pile foundation in the high-cold permafrost region of the present invention includes a formwork assembly 1 and a heat conduction assembly 2, the formwork assembly 1 includes a bottom form 11 and a side form 12, the bottom form 11 and the side form 12 are detachably connected, and the bottom form 11 communicates with the pouring cavity in the side form 12, the top surface of the side form 12 is provided with a pouring port 13, the heat conduction assembly 2 includes a horizontal pipe 21, a heat conduction main pipe 22, an extension pipe 23 and a flow guide 3, and the horizontal pipe 21 runs through Bottom mold 11, the middle part communicates with the bottom end of heat conduction mother pipe 22, heat conduction mother pipe 22 is vertically arranged in side mold 12 and its top is equal to the top surface of side mold 12, heat conduction mother pipe 22 is connected with the bottom of extension pipe 23, extends The top of the pipe ...

Embodiment 2

[0041] Such as figure 1 , 2 As shown, a concrete pile foundation in the high-cold permafrost region of the present invention includes a formwork assembly 1 and a heat conduction assembly 2, the formwork assembly 1 includes a bottom form 11 and a side form 12, the bottom form 11 and the side form 12 are detachably connected, and the bottom form 11 communicates with the pouring cavity in the side form 12, the top surface of the side form 12 is provided with a pouring port 13, the heat conduction assembly 2 includes a horizontal pipe 21, a heat conduction main pipe 22, an extension pipe 23 and a flow guide 3, and the horizontal pipe 21 runs through Bottom mold 11, the middle part communicates with the bottom end of heat conduction mother pipe 22, heat conduction mother pipe 22 is vertically arranged in side mold 12 and its top is equal to the top surface of side mold 12, heat conduction mother pipe 22 is connected with the bottom of extension pipe 23, extends The top of the pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com