A multi-stage telescopic hydraulic cylinder with staged independent extension and synchronous retraction

A telescopic hydraulic cylinder and cylinder barrel technology, which is applied in the field of hydraulic cylinders, can solve the problems of synchronous stability fluctuations, large space occupation, and stagnation, and achieve effective synchronous retraction, good stability, and weight reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

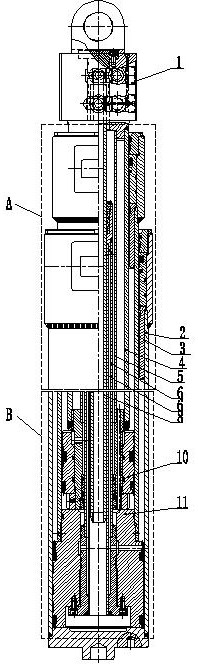

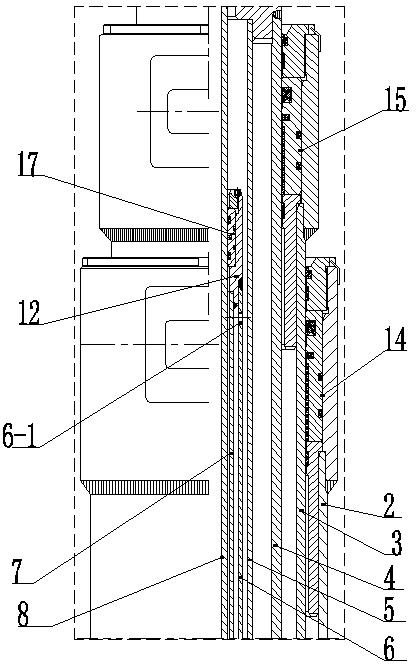

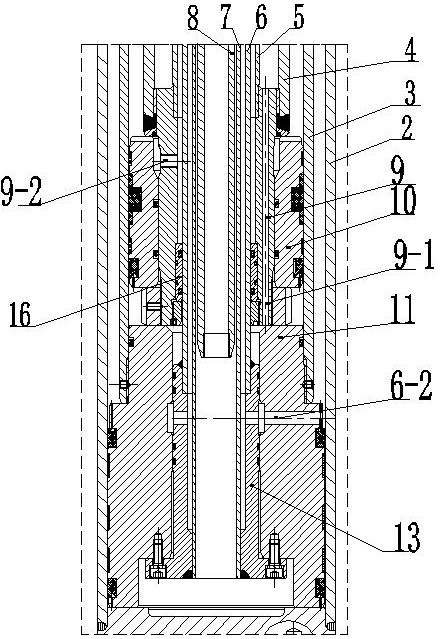

[0022] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

[0023] combine Figure 1 to Figure 3 As shown, a multi-stage telescopic hydraulic cylinder with staged independent extension and synchronous retraction, cylinder barrel 2, first-stage hollow piston rod 3, second-stage hollow piston rod 4, first-stage core tube 5, second-stage core tube 6. The third-stage core tube 7 and the fourth-stage core tube 8 are assembled sequentially from outside to inside, leaving gaps between adjacent parts.

[0024] The outer end of the first-stage core pipe 5, the outer end of the fourth-stage core pipe 8, and the outer end of the second-stage hollow piston rod 4 are connected to the earring body 1. The second-stage hollow piston rod 4 and the inner end of the first-stage core tube 5 are sealed and fixedly connected to the first rod head 9 , and the outer ends of the second-sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com