A sensor structure and its preparation method, strain monitoring method and device

A sensor and wave structure technology, applied in the field of sensors, can solve the problems of inability to monitor small-sized objects, limit the application of strain sensors, and large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

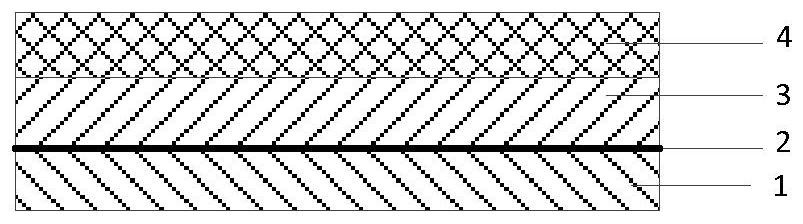

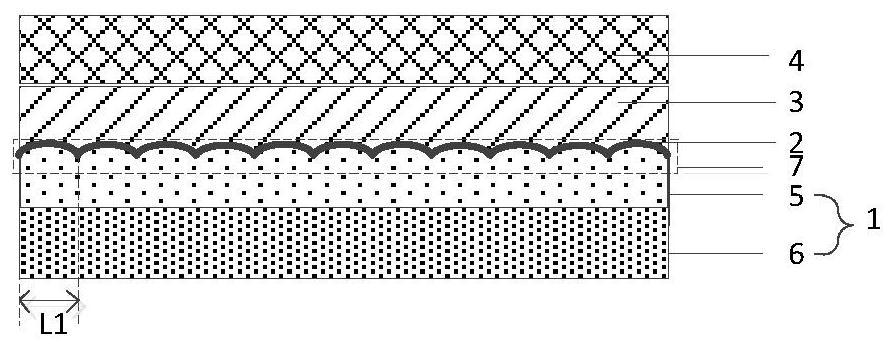

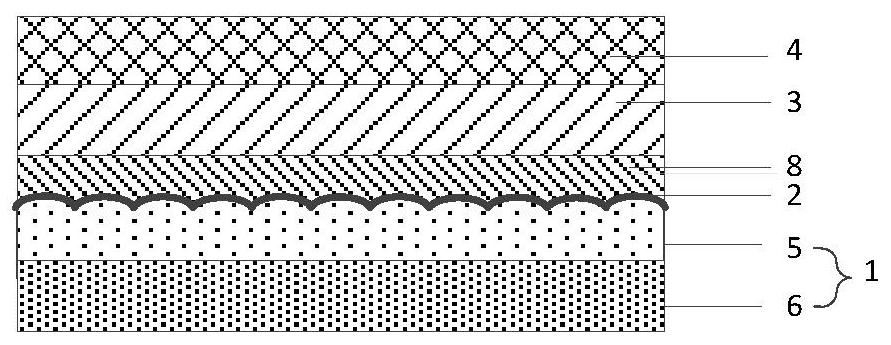

[0039] The embodiment of the present application provides a sensor structure, such as figure 1 As shown, the sensor structure includes: a conductive elastic layer 1, a nanowire electrode 2 attached to the conductive elastic layer 1, a luminescent functional layer 3 located on the nanowire electrode 2, and a luminescent functional layer 3 located on the luminescent functional layer. Flexible electrode 4 on top of layer 3.

[0040] The sensor structure provided by the embodiment of the present application includes an OLED device composed of a nanowire electrode attached to the conductive elastic layer, a light-emitting functional layer, and a flexible electrode. Since the nanowire electrode is attached to the conductive elastic layer, the tensile strain Under the action, the spreading degree and arrangement of the nanowires will change, and then the surface resistance of the electrode will change, and the current of the sensor structure will change accordingly. The parameters o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com