Multi-tab coiled lithium ion battery pole piece and preparation method thereof

A lithium-ion battery, wound-type technology, applied in the field of lithium-ion batteries, can solve the problems of punctured diaphragm battery short circuit, battery cost increase, etc., to achieve the effect of reducing cumulative tolerance, reducing battery cost, and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

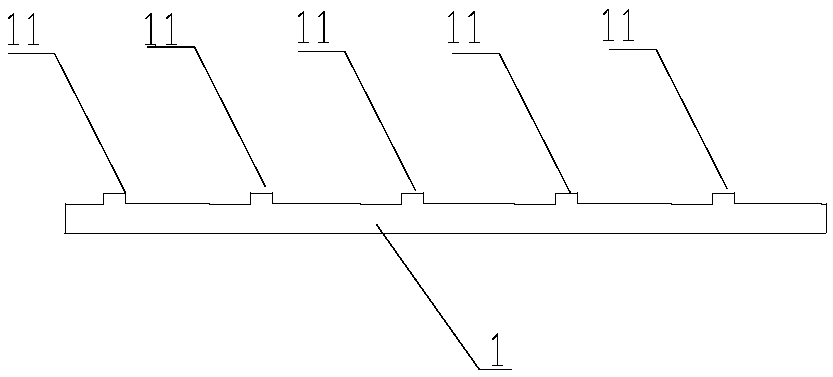

[0026] Such as figure 2 As shown, this embodiment adopts a knife die, and die-cuts five tabs 11 on the pole piece body 1, the width of adjacent tabs 11 increases by 1.7mm in turn, and the distance between two adjacent tabs 11 Both are 67.73mm.

Embodiment 2

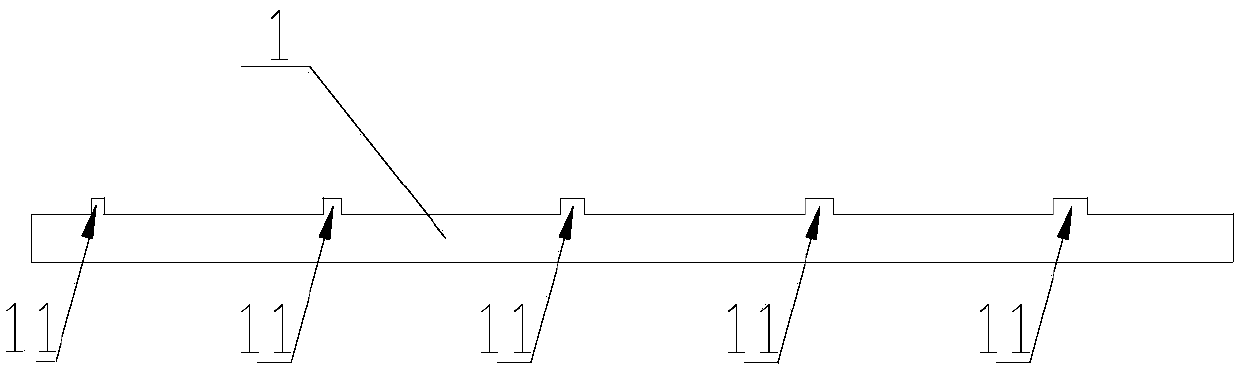

[0028] Such as image 3 As shown, this embodiment adopts 2 cutting dies, and die-cuts 10 pole lugs 11 on the pole piece body 1, wherein the first to fifth pole lugs 11 from left to right are the first group, and the first Die-cutting, the width of adjacent tabs 11 increases by 1.7mm in turn, and the distance between adjacent tabs 11 is 67.73mm; the 6th to 10th tabs 11 are the second group, and the adjacent tabs 11 The width increases by 1.7mm in turn, and the distance between adjacent tabs is 76.26mm. The distance between the fifth and sixth tabs can be the length of the first die or the length of the second die.

Embodiment 3

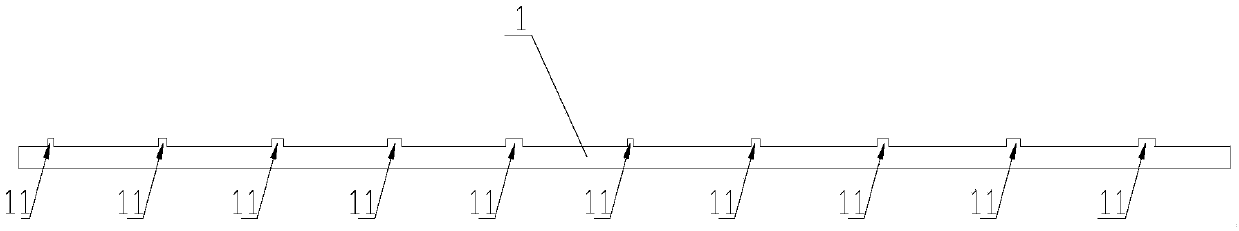

[0030] Such as Figure 4 As shown, in this embodiment, 3 cutting dies are used to die-cut 15 tabs, among which, the first to fifth tabs 11 from left to right are the first group, which are die-cut with the first die-cutting die, adjacent to each other. The width of tabs 11 increases by 1.7mm in turn, and the distance between adjacent tabs 11 is 67.73mm; the 6th to 10th tabs 11 are the second group, which are die-cut with the second knife, and the adjacent tabs The width of 11 increases by 1.7mm in turn, and the distance between adjacent tabs is 76.26mm. The distance between the fifth and sixth tabs can be the length of the first die or the length of the second die; The 11th to 15th tabs 11 are the third group, die-cut with the third knife, the width of adjacent tabs 11 increases by 1.7mm, the distance between adjacent tabs is 84.80mm, the 10th The distance from the 11th tab can be the length of the second die or the length of the third die.

[0031] Since the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com