Device and method for automatically suppressing milling vibration of thin-walled rotating body

A technology of thin-wall rotation and automatic suppression, which is applied in positioning devices, manufacturing tools, clamping, etc., can solve problems such as large cutting vibrations, and achieve the effect of achieving processing quality requirements and fixture self-adaptation process easily and quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

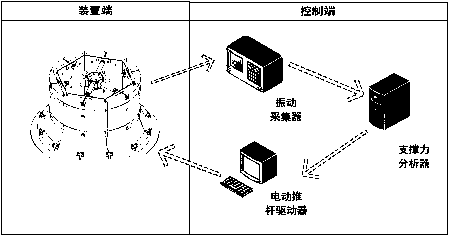

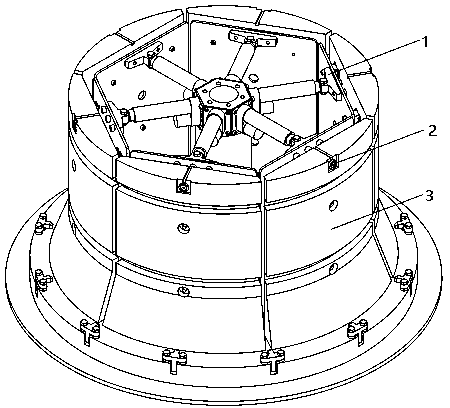

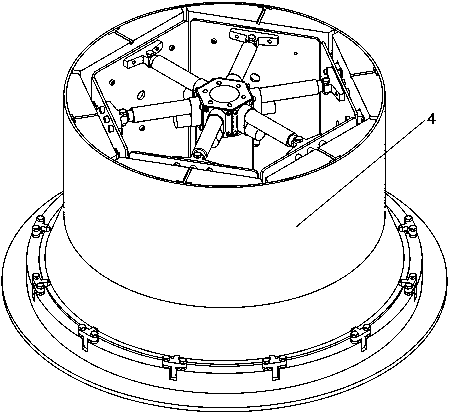

[0052] first as figure 2 As shown in the figure, assemble the fixture, install the fixture vertically on the base of the five-axis vertical machining center, connect the push rod motor 13, vibration sensor 15, and force sensor 2 to the electric control system, and then push The front end 5 of the rod is retracted to drive the support plate 19 and the damping block 3 back, and the workpiece 4 is placed from top to bottom; by controlling the start and stop of the motor 13, the gear and the ball screw are driven to rotate to realize the front end 5 of the push rod and the damping block 3 After fully fitting with the workpiece 4, rotate the quick-release pressure plate 17 and use bolts to connect with the base 18 to compress the workpiece 4 and start processing; the vibration sensor 15 continuously monitors the vibration during processing and transmits data to the computer, and the system processes the data to obtain After the current required supporting force is obtained, the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com