Rotary glass hot bending molding furnace

A molding furnace and rotary technology, applied in glass molding, glass re-molding, glass manufacturing equipment, etc., can solve the problems of low production efficiency and low thermal insulation efficiency, and achieve improved efficiency, improved thermal insulation effect, and improved finished products. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further elaborated below in conjunction with the accompanying drawings.

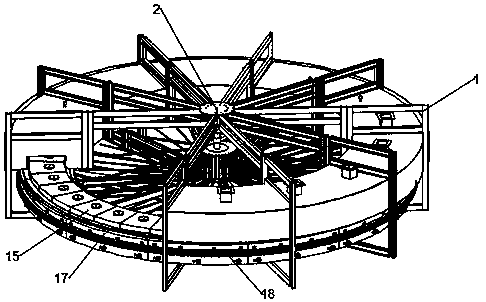

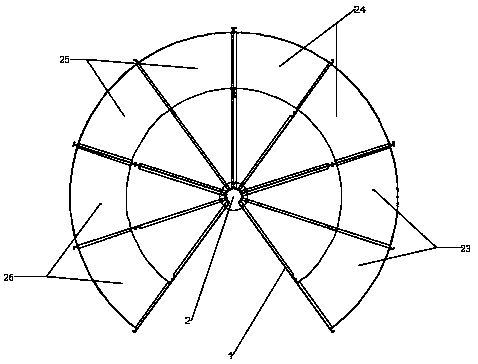

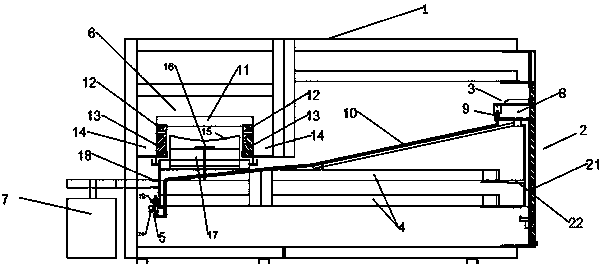

[0020] refer to figure 1 , figure 2 , image 3 As shown, one embodiment of the present invention is a rotary glass hot-bending forming furnace, which includes a furnace frame 1, and a spindle mechanism 2 is installed in the furnace frame 1, which is used to make the hot-bending glass pass through the spindle mechanism 2 during the forming process. Drive the hot-bending glass to the corresponding production area, and install a vacuum adsorption device 3 on the upper part of the spindle mechanism 2 to adjust the air pressure in the vacuum tube, so that the stainless steel suction cup 16 absorbs the glass, so that the glass is hot-bent and shaped, and passes through the spindle Rotating brackets 4 are installed at intervals on the bottom of the mechanism 2, which are used to support the hot bending mold 15 through the rotating bracket 4 during the rotation of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com