PHC material recycling technology, and sheet material prepared from recycled PHC material

A technology of recycled materials and crafts, applied in the field of boards, can solve problems such as cost waste and environmental pollution, and achieve the effects of reducing pollution, cost-effective, and solving the problem of whereabouts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The application will be further described below in conjunction with specific embodiments, so that those skilled in the art can better understand the application and implement it, but the examples given are not intended to limit the application.

[0011] The application provides a recovery process for PHC materials. The recovery process is as follows: crush the recovered PHC material into powder, mix the powdered PHC material with the liquid polyurethane material, spread it into the mold, and press it through the mold. Combined to form a sheet. The temperature of mold pressing is 130°C to 150°C. The mass ratio of the powdered PHC material to the commercial polyurethane material is 1:1-9:1. The pressing pressure of the mold is 100t~500t. The present application also provides a board made of recycled PHC material, which is manufactured by the above-mentioned recycling process.

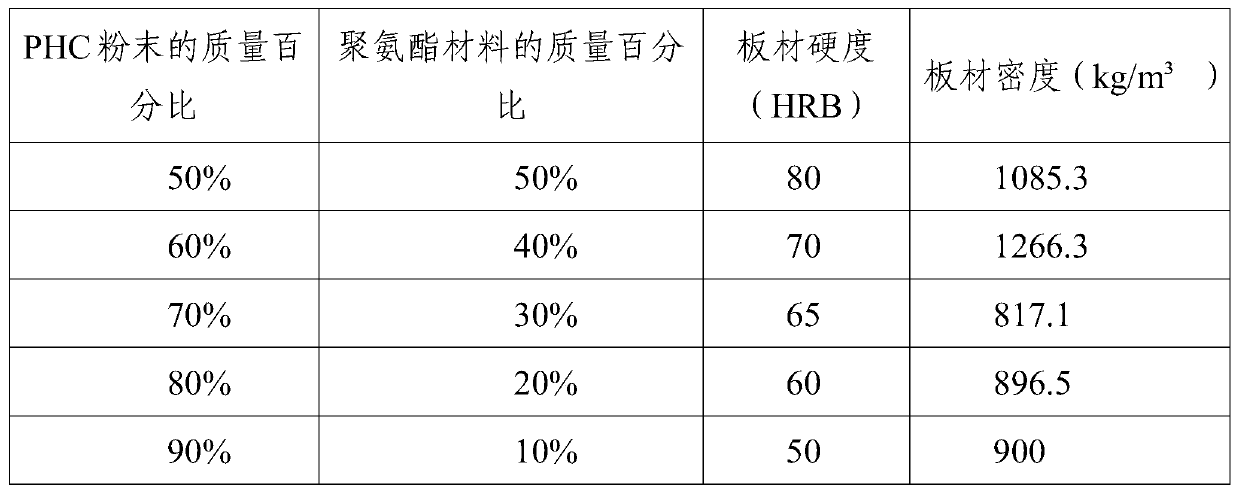

[0012] The mixing mass percentage of PHC powder and polyurethane material is different, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com