Weathering-resistant steel for high-strength low-yield-strength-ratio weathering-resistant carriage and preparation method thereof

A low-yield-strength, high-strength technology, applied in the field of weathering steel for high-strength low-yield-ratio weathering carriages and its preparation, can solve the problem of not considering the need for hot rolling, building slow cooling pits, and not reserving construction delays. Cold pit site space and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

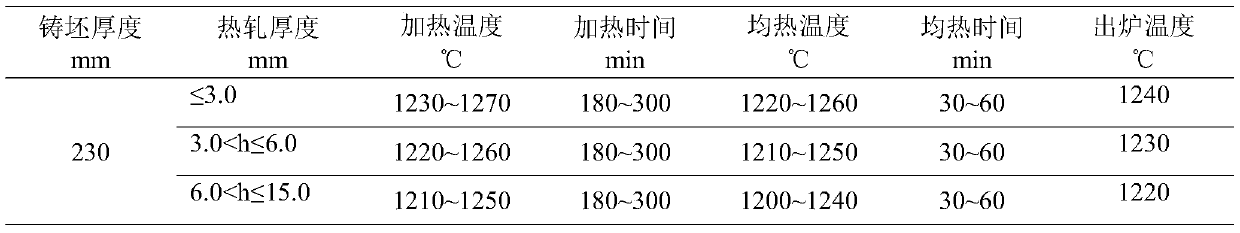

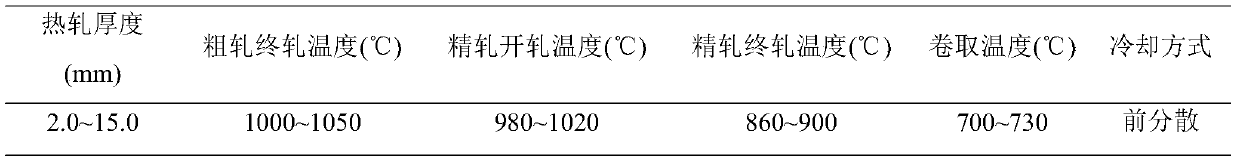

[0015] 1. Product production process route

[0016] Hot metal pretreatment—converter top and bottom combined blowing smelting—LF refining outside furnace—slab continuous casting—slow cooling

[0017] Slab heating—high pressure water descaling—fixed width press—E1R1 roughing mill rolling—E2R2 roughing mill rolling—flying shear—high pressure water descaling—F1~F7 finishing mill rolling—intensive laminar cooling—coiling - Pallet transportation system - Warehouse - Slow cooling under the insulation cover - Sampling and inspection after 48 hours - Weighing and packaging.

[0018] 2. Steelmaking process

[0019] 2.1 Smelting process

[0020] 2.1.1 Converter smelting: molten iron is pretreated and desulfurized for converter smelting, oxygen is blown to decarburize and the temperature is raised, ferrosilicon and ferromanganese are added for deoxidation and alloying in the later stage of smelting, P and S components are controlled, and molten steel is prevented from overoxidation. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com