A kind of high-strength anti-corrosion stainless steel, oil casing and manufacturing method thereof

A manufacturing method and anti-corrosion technology, applied in the direction of casing, manufacturing tools, drill pipes, etc., can solve problems such as unsatisfactory service safety, and achieve good anti-acidification liquid corrosion performance, excellent anti-corrosion performance, excellent anti-corrosion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

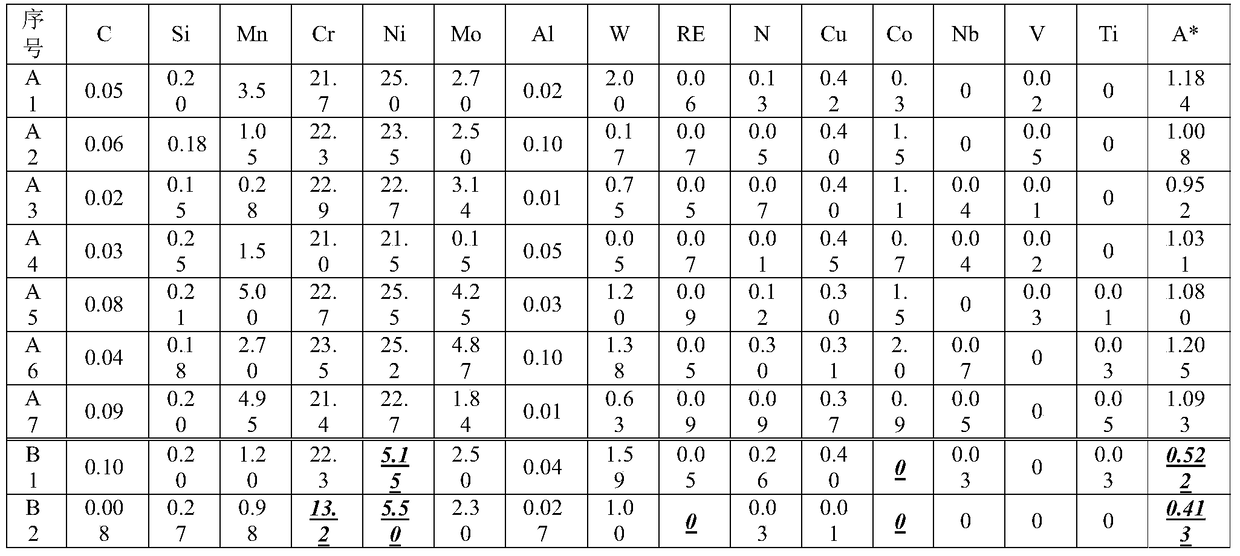

Embodiment A1-A7 and comparative example B1-B2

[0064] The oil-casing pipes in the above-mentioned embodiments and comparative examples are manufactured through the following steps (Table 2 shows the specific process parameters of each embodiment and comparative examples):

[0065] (1) Smelting and preparing the tube billet: In the smelting process, the electric arc furnace or converter + secondary refining process is used to control the mass percentage of each chemical element as shown in Table 1; then, continuous casting or die casting + forging is adopted The tube blank is made by the way;

[0066] (2) Heating the tube billet: the tube billet is heated above the austenitizing temperature by using a ring heating furnace;

[0067] (3) Tube making: tube making by perforation + hot rolling or hot extrusion;

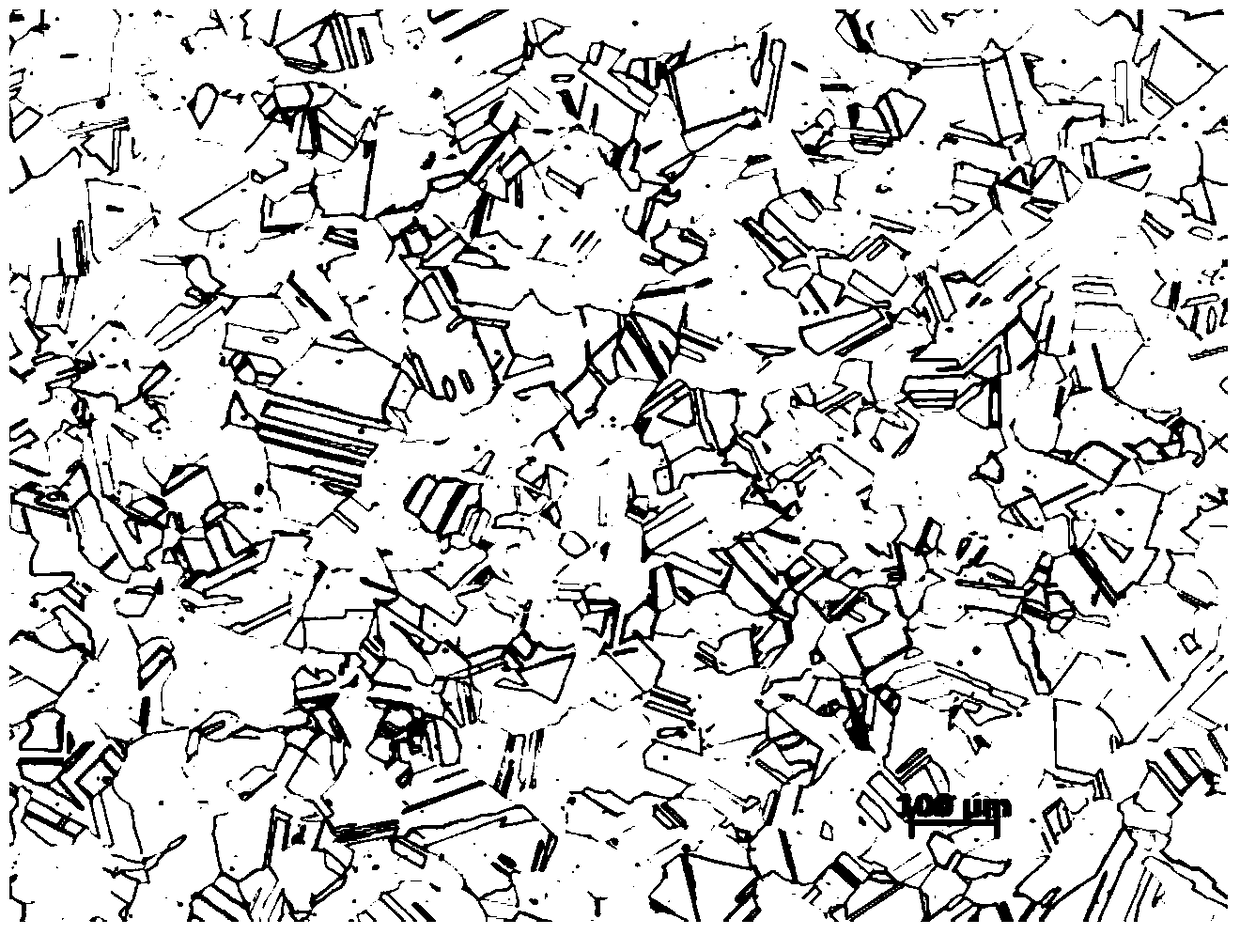

[0068] (4) Solution heat treatment: the solution temperature is 980-1200°C, and then cooled to below 300°C at a rate of 15-25°C / S, so that the microstructure in the oil casing can be transformed into a single solid sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com