A kind of high chromium corrosion-resistant steel and its preparation method and application

A corrosion-resistant steel and high-chromium technology, applied in the field of high-chromium corrosion-resistant steel and its preparation, can solve the problems of high price, difficulty in popularizing construction steel, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

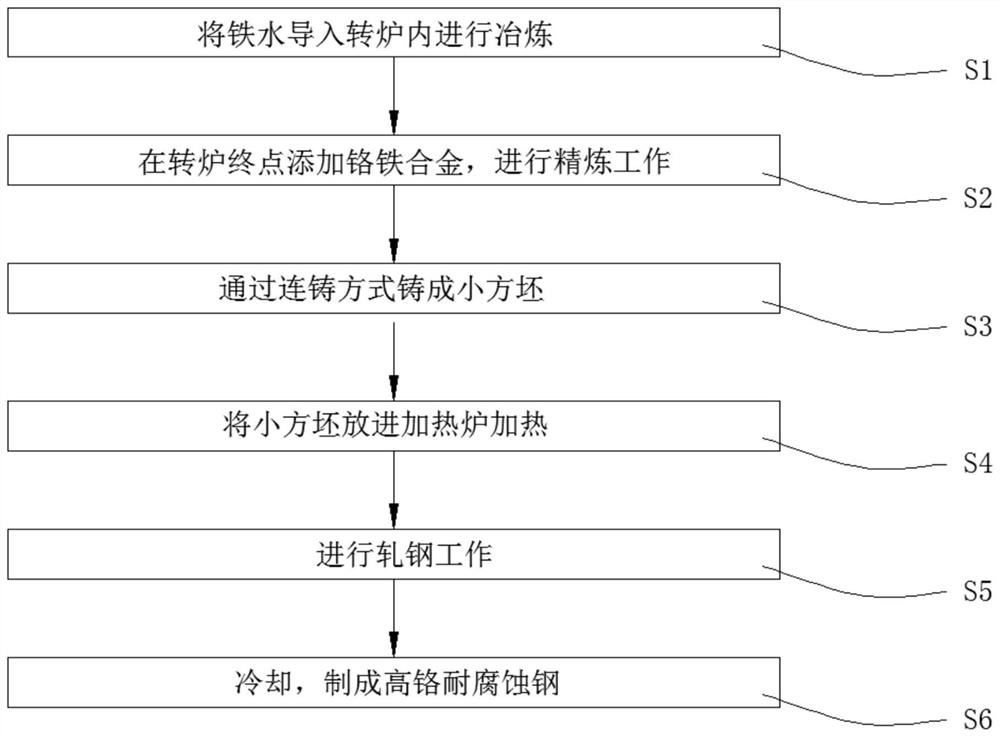

[0032] The embodiment of the present invention also provides a method for preparing high-chromium corrosion-resistant steel, which is used to prepare the above-mentioned high-chromium corrosion-resistant steel. The method includes:

[0033] The molten steel is adjusted according to the chemical composition of the mass fraction, and the adjusted molten steel is subjected to smelting, refining, continuous casting, billet heating, rough rolling, finish rolling and cooling to obtain high chromium corrosion-resistant steel.

[0034] Specifically, in the continuous casting, full-protection casting is adopted, and the inclusion control level is ≤1.5.

[0035] Specifically, during the heating of the slab, the heating temperature is 1185-1215°C.

[0036] Specifically, in the rough rolling, the rolling start temperature is 1035-1065°C.

[0037] Specifically, in the finish rolling, the finish rolling temperature is 845-875°C.

[0038] Specifically, in the cooling, the temperature is co...

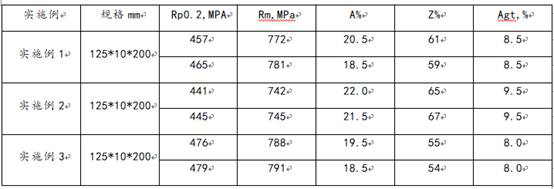

Embodiment 1

[0044] The high-chromium corrosion-resistant steel provided in this embodiment includes the chemical composition of the following mass fractions:

[0045] C: 0.04%, Si: 0.66%, Mn: 0.66%, P: 0.009%, S: 0.003%, Cr: 7.45%, N: 0.0056%, and the rest are Fe and unavoidable impurities.

[0046] The present embodiment also provides the preparation method of the high-chromium corrosion-resistant steel, including:

[0047] Blending molten steel according to the chemical composition of the mass fraction, smelting, refining, continuous casting, casting slab heating, rough rolling, finish rolling and cooling the blended molten steel to obtain high chromium corrosion-resistant steel;

[0048] In continuous casting, full protection pouring is adopted, and the inclusion control level is ≤1.5;

[0049] During billet heating, the heating temperature is 1190°C;

[0050] During rough rolling, the rolling start temperature is 1040°C;

[0051]During finish rolling, the finish rolling temperature...

Embodiment 2

[0054] The high-chromium corrosion-resistant steel provided in this embodiment includes the chemical composition of the following mass fractions:

[0055] C: 0.03%, Si: 0.5%, Mn: 0.5%, P: 0.005%, S: 0.002%, Cr: 6.5%, N: 0.0040%, and the rest are Fe and unavoidable impurities.

[0056] The present embodiment also provides the preparation method of the high-chromium corrosion-resistant steel, including:

[0057] Blending molten steel according to the chemical composition of the mass fraction, smelting, refining, continuous casting, casting slab heating, rough rolling, finish rolling and cooling the blended molten steel to obtain high chromium corrosion-resistant steel;

[0058] In continuous casting, full protection pouring is adopted, and the inclusion control level is ≤1.5;

[0059] During billet heating, the heating temperature is 1185°C;

[0060] During rough rolling, the rolling start temperature is 1035°C;

[0061] During finish rolling, the finish rolling temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com