Welding stirrup construction method capable of replacing cast-in-place distributing reinforcement

A construction method and technology of cast-in-place slabs, which are applied to structural elements, building components, building reinforcements, etc., can solve the problems of inadequate control of the protective layer, scattered ordinary stirrups, and insufficient stirrup strength, so as to ensure the thickness of the protective layer of steel bars , Improve construction quality and efficiency, and achieve good overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A construction method for welding stirrups that can replace cast-in-place slab distributed reinforcement, comprising the following steps:

[0035] (1) Design and manufacture of welding stirrup mold

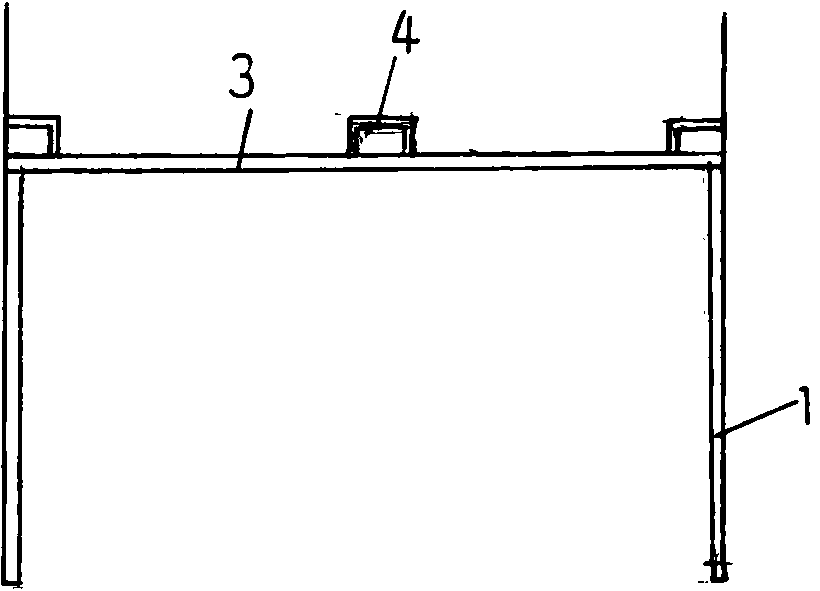

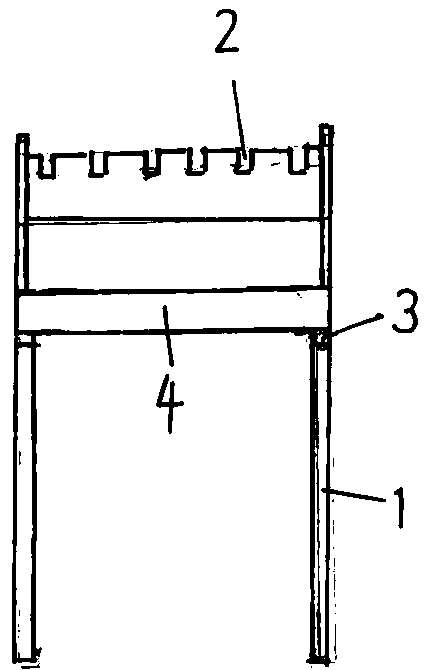

[0036] a. Welding stirrup mold is composed of bottom support 1, middle tray, and slots 2 on both sides; the bottom support is made of 4 pieces of 50cm long and 20mm diameter rebar, the middle tray is composed of transverse rib 3 and longitudinal rib 4, and the transverse rib Two 1-meter-long and 20mm-diameter rebars are used, three 45cm-long 8# channel steels are used for the longitudinal ribs, and steel plates with a length*width*thickness of 35cm*8cm*5mm are used for the grooves on both sides;

[0037] b. The height control of the bottom opening of the stirrup mold slot is the key work. According to different design plate thicknesses, the height of the bottom opening of the slot corresponding to it is calculated, and the height of the bottom opening of the stirrup mold sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com