Engineering machinery differential lock differential mechanism

A technology for construction machinery and differentials, applied in mechanical equipment, differential transmissions, belts/chains/gears, etc., can solve problems such as the loss of differentials, and achieve the effect of avoiding rigid impact and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

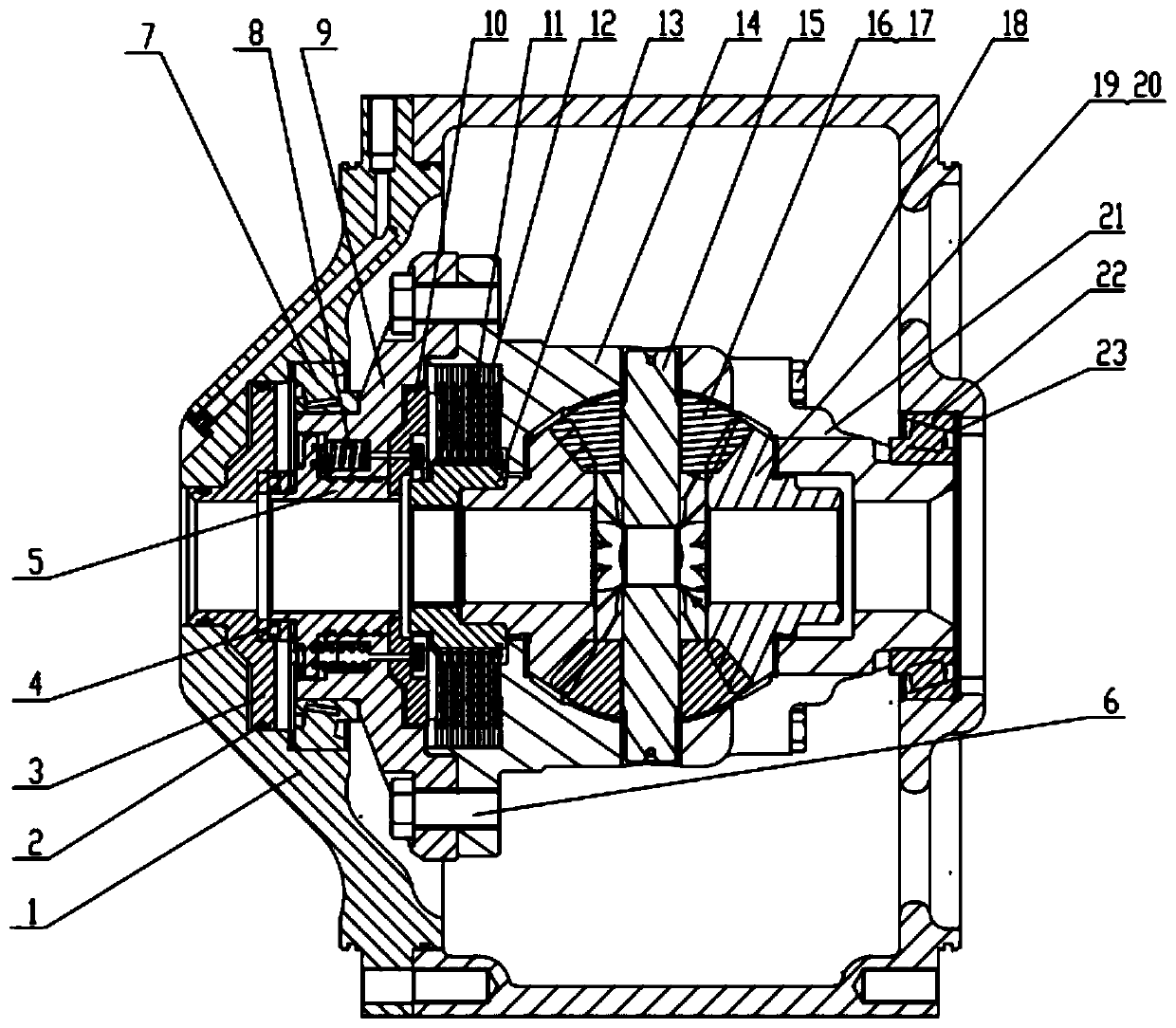

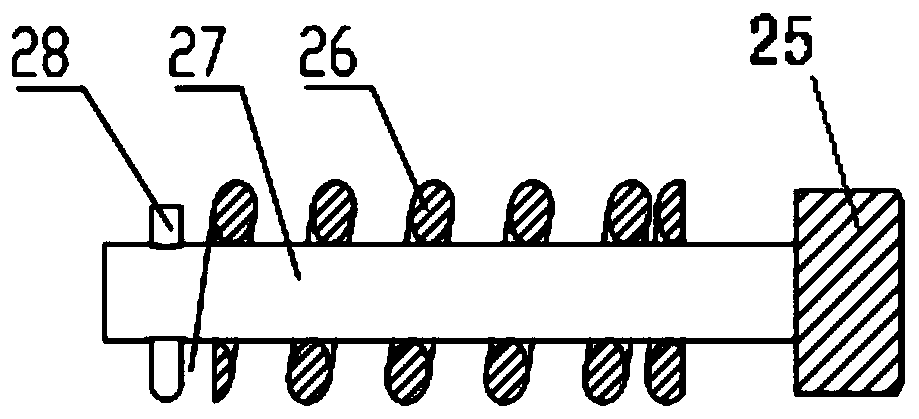

[0034] Depend on Figure 1 to Figure 4 As shown, a construction machinery differential lock differential of the present invention includes a spline sleeve 13, a pressure plate 10, a friction plate 11, a driven plate 12, and a transition sleeve 5 arranged on one half shaft of the differential. , Return spring assembly 8 and end cap 9.

[0035] Differential gear left housing 14 and differential gear right housing 21 are fixed as a whole by bolt I 18 after coupling, and cross shaft 15, planetary gear 16, planetary gear spacer 17, half shaft gear 19, half shaft are housed in its inner space. Gear spacer 20. A spline sleeve 13 which can be engaged with an external spline on the half shaft is sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com