An early air cut-off device for gear shift assist system

A power-assisting system and air-cutting technology, which is applied in transmission control, components with teeth, belts/chains/gears, etc., can solve the problems of affecting the performance and life of the synchronizer, precise control of the timing of the end of the lack of assistance, and achieve a simple structure. , strong practicability and sensitive action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] First of all, it needs to be explained that the orientation words such as up, down, left, right, front, and back described in the present invention are only described according to the accompanying drawings, so as to facilitate understanding, and are not intended to limit the technical solution and scope of protection of the present invention. .

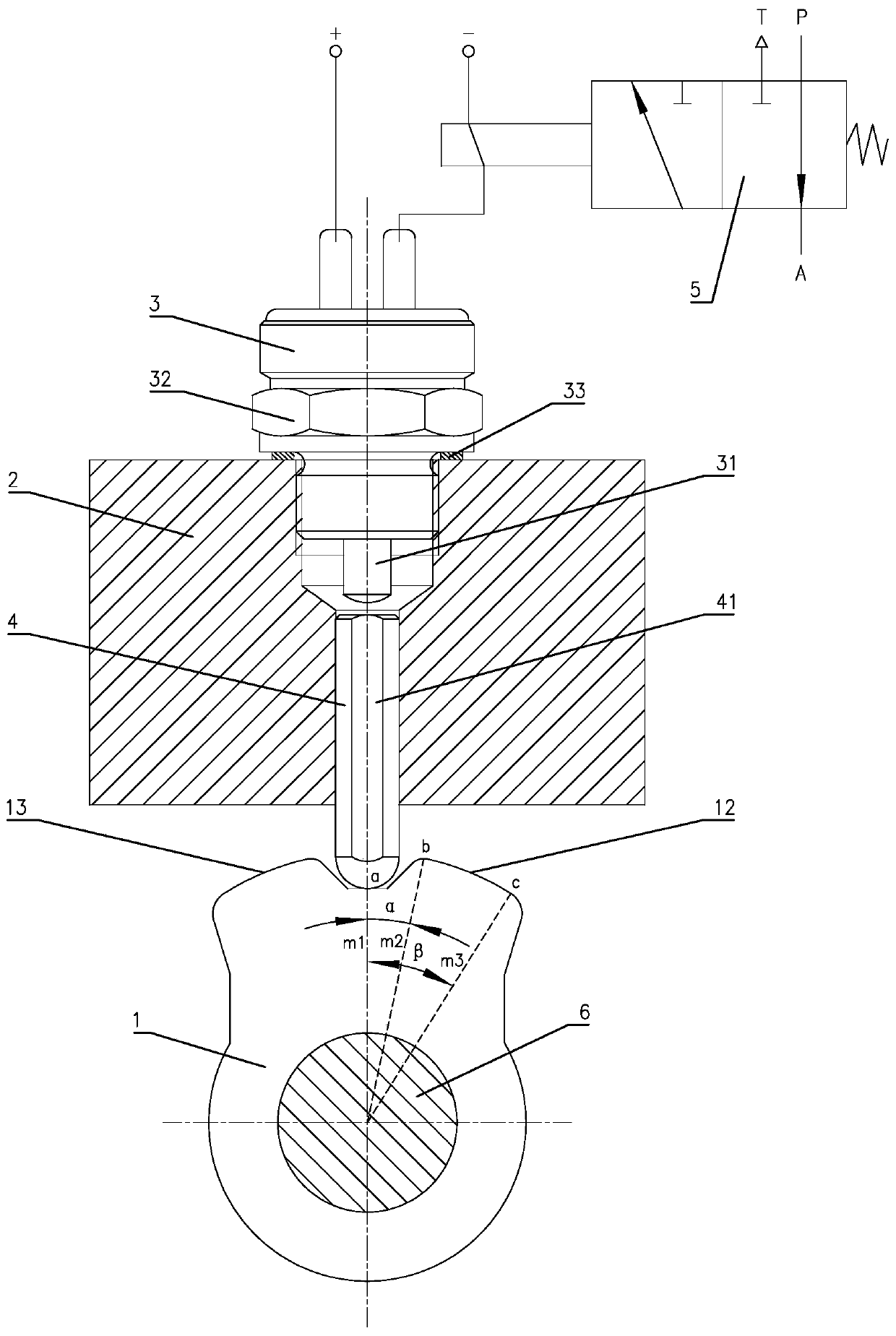

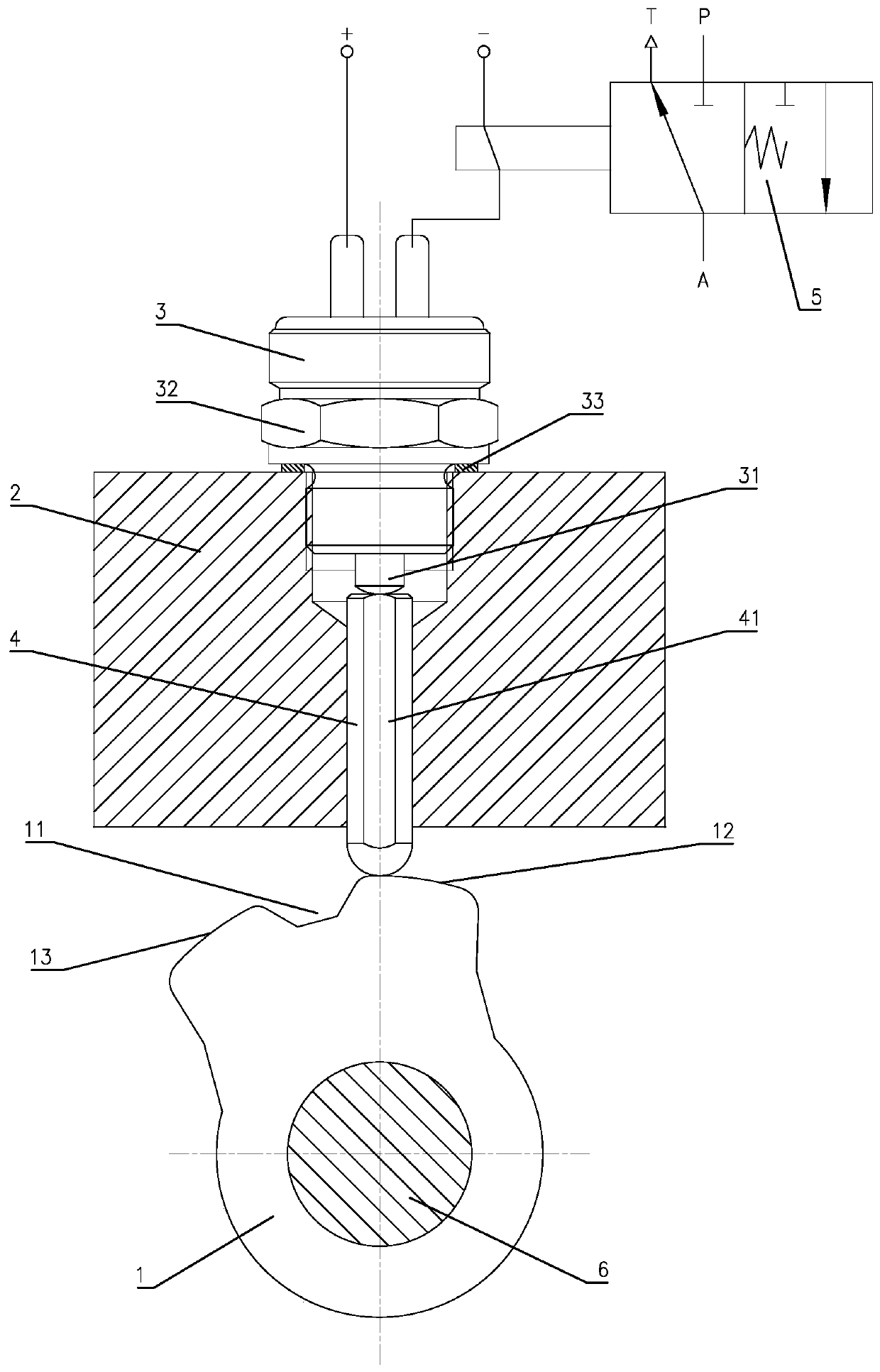

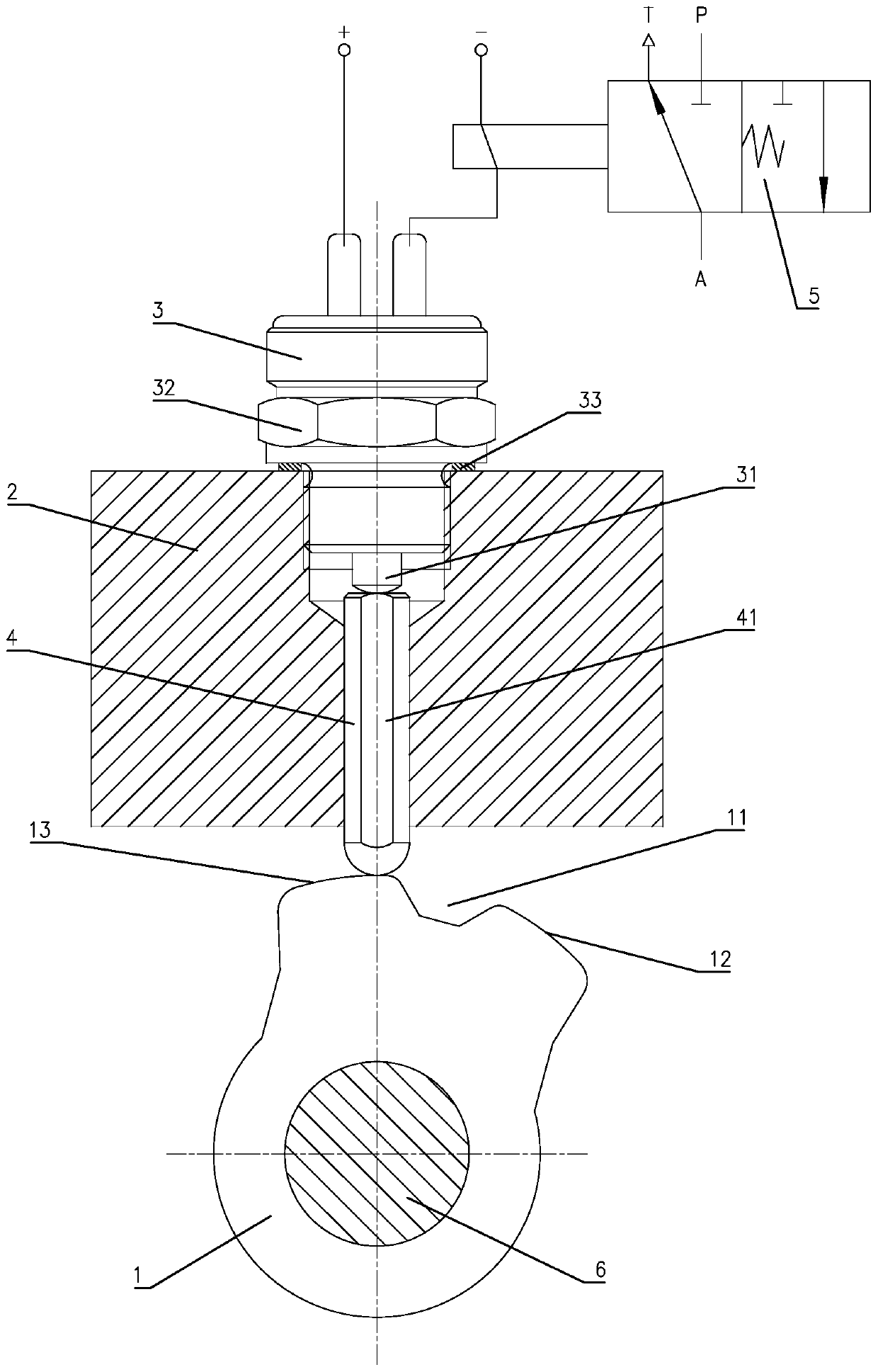

[0020] Such as Figure 1 to Figure 3 Shown is a specific embodiment of an early air cut-off device for a shift assist system of the present invention, including a shift trigger block 1 , a fixed seat 2 , a trigger switch 3 , a trigger push rod 4 and an electromagnetic control valve 5 . Fix the shift trigger block 1 on the shift shaft 6 of the gearbox, and set a neutral gear groove 11 on the top of the shift trigger block 1 with a notch width greater than the groove bottom width, and on both sides of the neutral gear groove 11 Correspondingly set the front shifting arc-shaped protrusion 12 and the rear shifting arc-shaped protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com