Weighing device and horizontal type cement bin

A weighing device and mounting plate technology, which is applied in the direction of measuring devices, detailed information of weighing equipment, weighing, etc., can solve the problems of damage to the load cell, poor use effect, heavy weight, etc., and achieve high safety , Simple structure, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

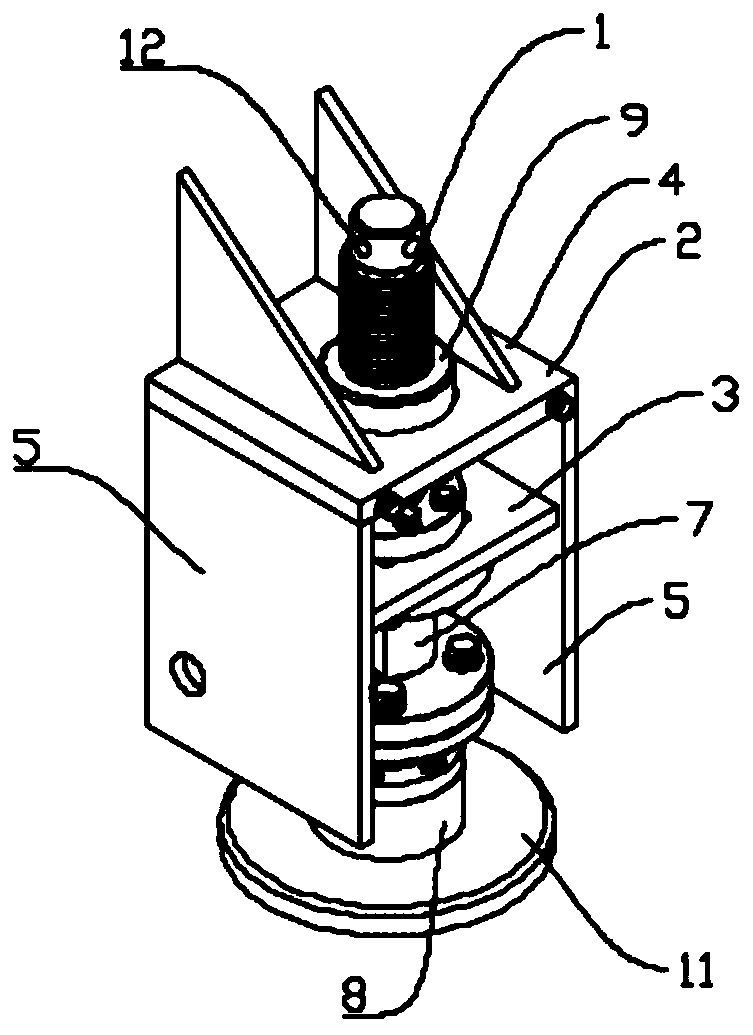

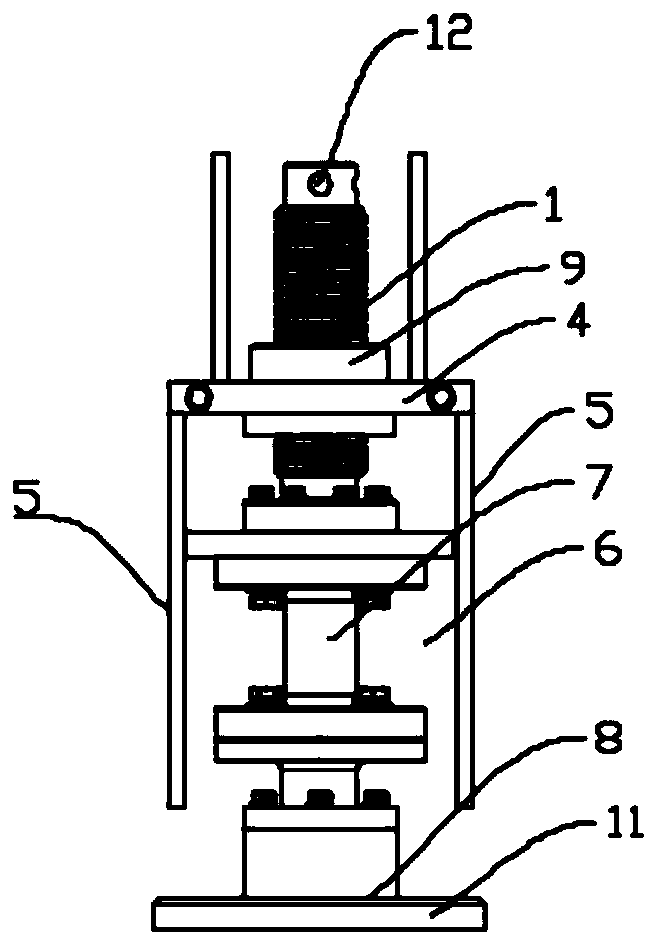

[0038] Such as figure 1 , figure 2 As shown, this embodiment provides a weighing device, including a telescopic structure and a tension and compression sensor 7. The telescopic structure includes a screw rod 1, a fixing base 2 and a screw base 3. The fixing base 2 includes a mounting plate 4 and a symmetrical installation The limit support plate 5 at both ends of the plate 4, the limit support plate 5 is perpendicular to the mounting plate 4, the area between the limit support plates 5 is the limit zone 6, the screw rod 1 is threaded with the mounting plate 4, and the screw rod 1 is located One end of the limit zone 6 rotates and fits with the screw base 3 through a bearing. The screw base 3 is located in the limit zone 6 and both ends of the screw base 3 slidably cooperate with the limit support plate 5, and the tension and compression sensor 7 is fixed on The lower end of the screw base 3.

[0039] Specifically, the fixing base 2 is fixedly installed at the lower end of the eq...

Embodiment 2

[0044] This embodiment is optimized and defined on the basis of the foregoing embodiment 1.

[0045] It also includes a sensor base 8 fixed on the lower end of the tension and compression sensor 7, and the sensor base 8 is fixedly connected to the tension and compression sensor 7 by bolts.

[0046] The sensor base 8 is designed to avoid direct contact between the tension and compression sensor 7 and the supporting surface, and can protect the tension and compression sensor 7 from collisions, thereby achieving high safety and good stability.

Embodiment 3

[0048] This embodiment is optimized and defined on the basis of the foregoing embodiment 2.

[0049] In order to facilitate the installation of the screw rod 1, a nut 9 is provided in the middle of the mounting plate 4. The screw rod 1 and the nut 9 are threadedly matched, and the axes of the screw rod 1, the tension and compression sensor 7 and the sensor base 8 are consistent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com