Display panel and making method thereof

A technology for display panels and manufacturing methods, applied in optics, instruments, electrical components, etc., can solve the problem that the frame size of display panels cannot be further reduced, and achieve the effects of narrow frames, reduced impedance, and space-saving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] In order to enable those skilled in the art to further understand the present invention, the preferred embodiments of the present invention are listed below, and the composition and desired effects of the present invention are described in detail with reference to the accompanying drawings. It should be noted that the drawings are all simplified schematic diagrams, therefore, only the components and combinations related to the present invention are shown to provide a clearer description of the basic structure or implementation method of the present invention, and the actual components and layout may be more accurate. for complex. In addition, for the convenience of description, the components shown in the drawings of the present invention are not drawn in proportion to the number, shape, and size of the actual implementation, and the detailed proportions can be adjusted according to design requirements.

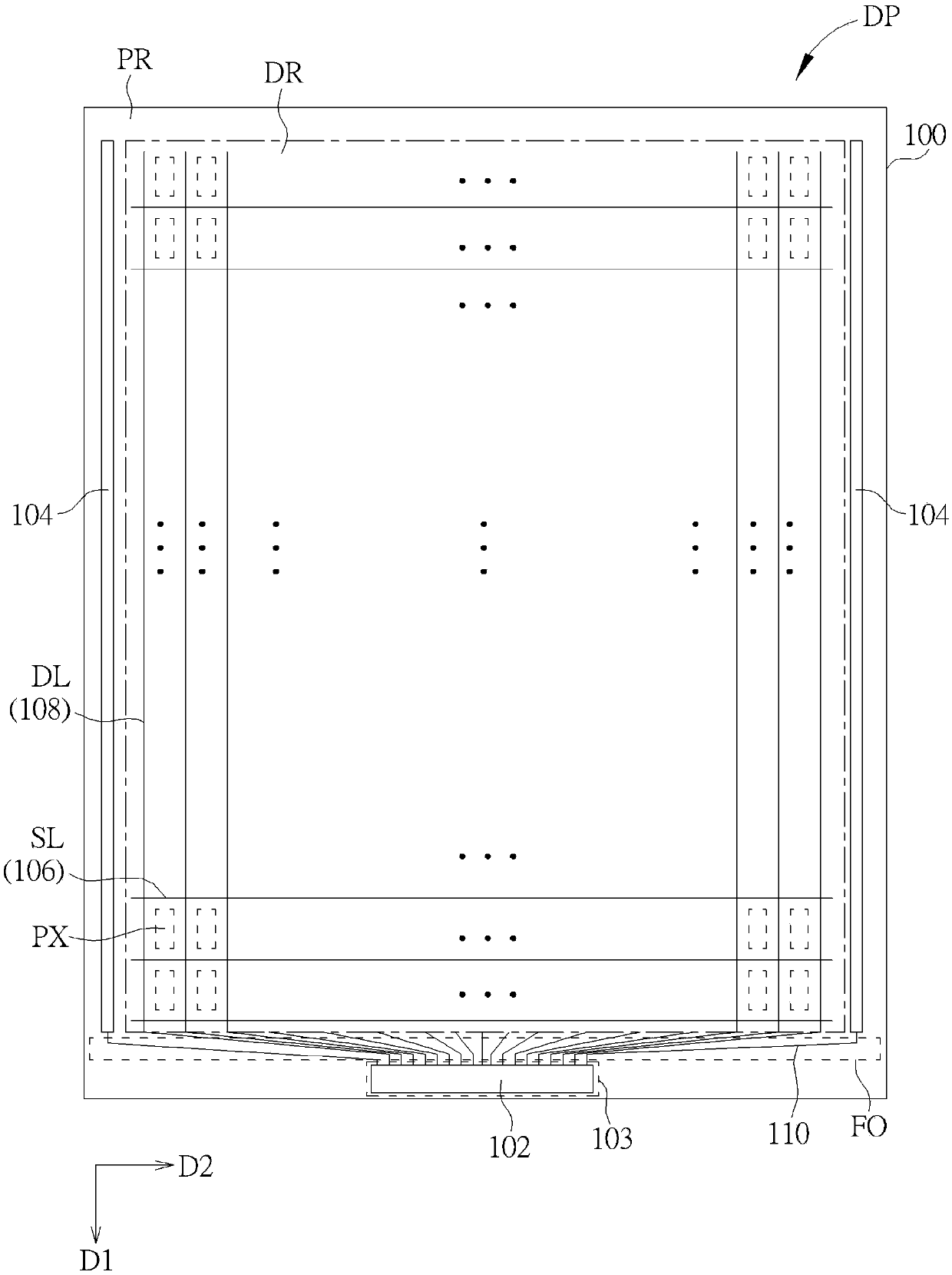

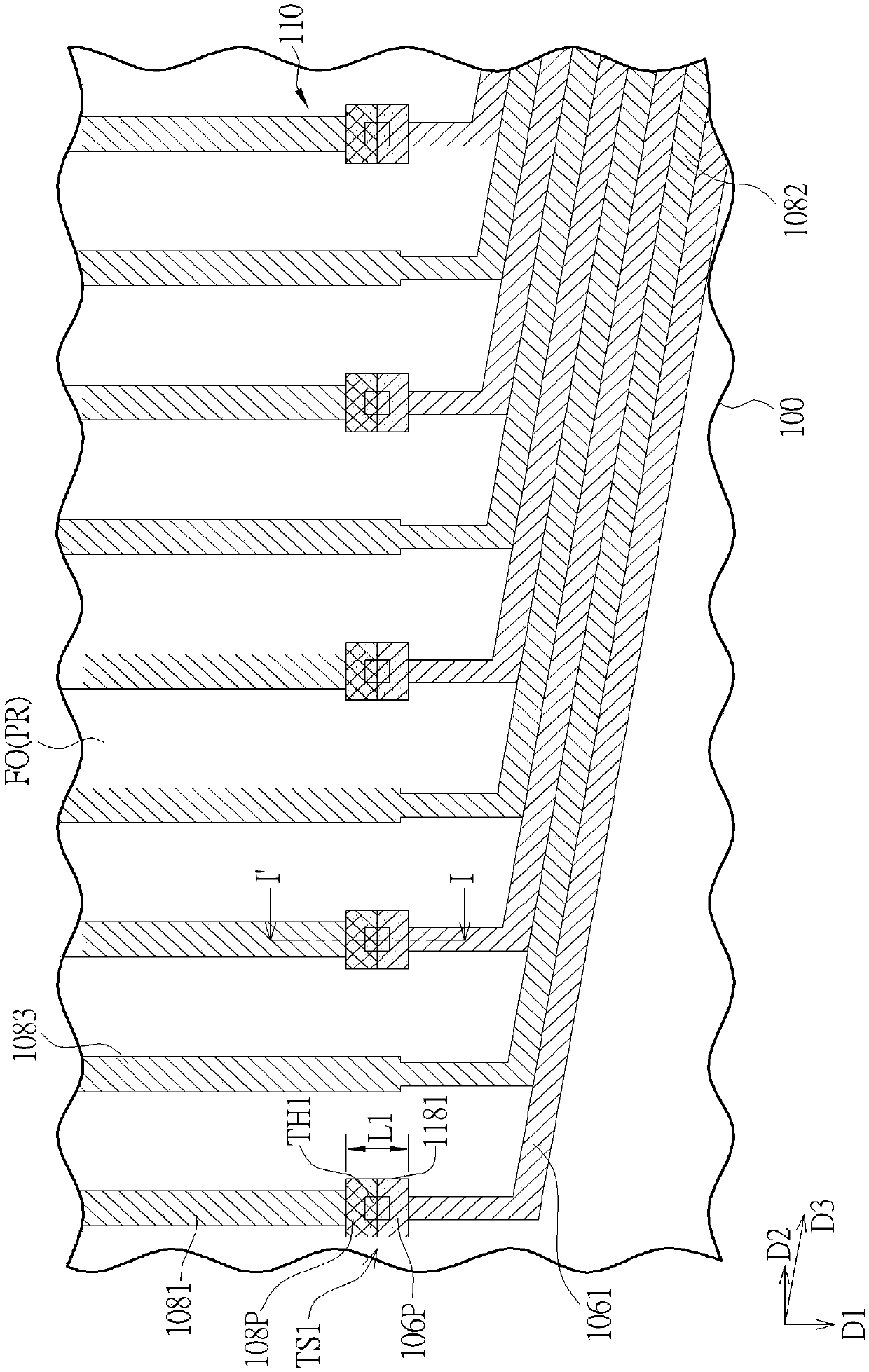

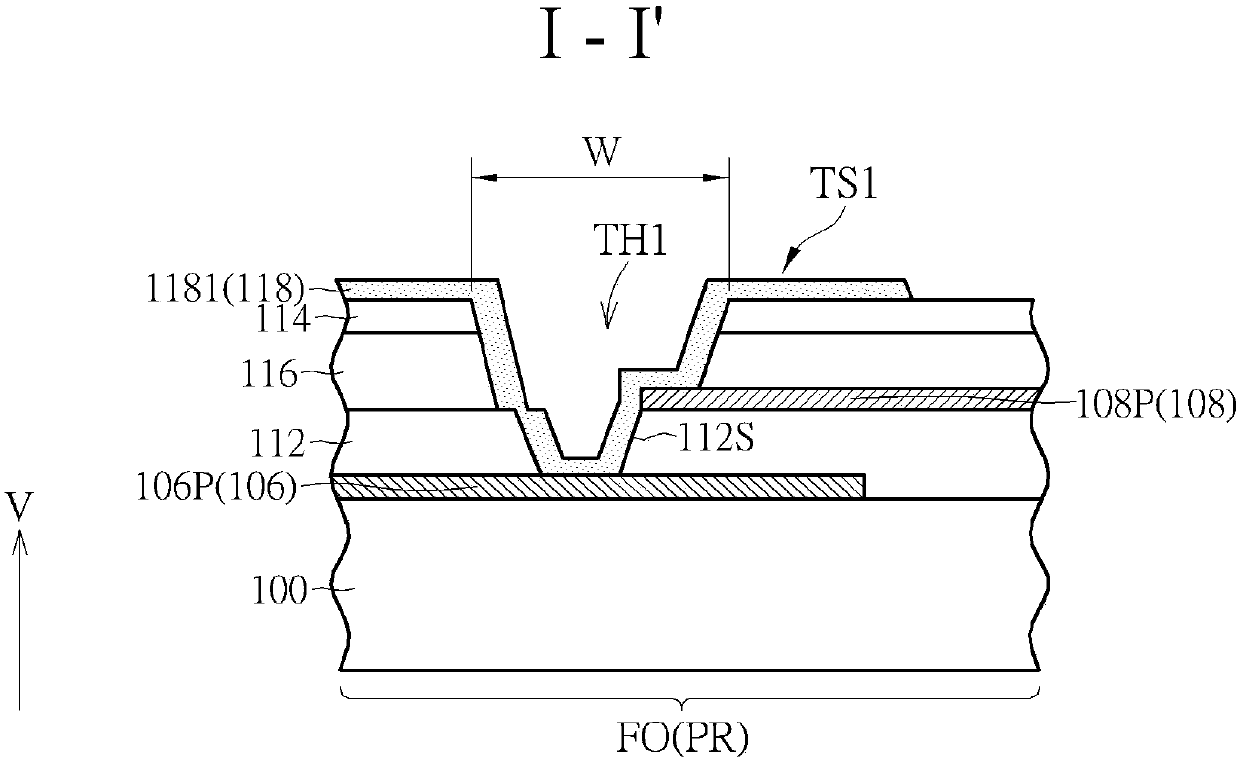

[0116] Please refer to Figure 1 to Figure 3 , figure 1 is a sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com