Thick film hybrid circuit pin connection structure and method

A thick-film mixed and connected structure technology, which is applied in the direction of circuits, electrical components, and electrical solid devices, can solve problems such as inconsistent expansion coefficients, poor quality consistency, and low production efficiency, and achieve reduced production accuracy, safe and reliable use, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in detail below in conjunction with specific embodiments.

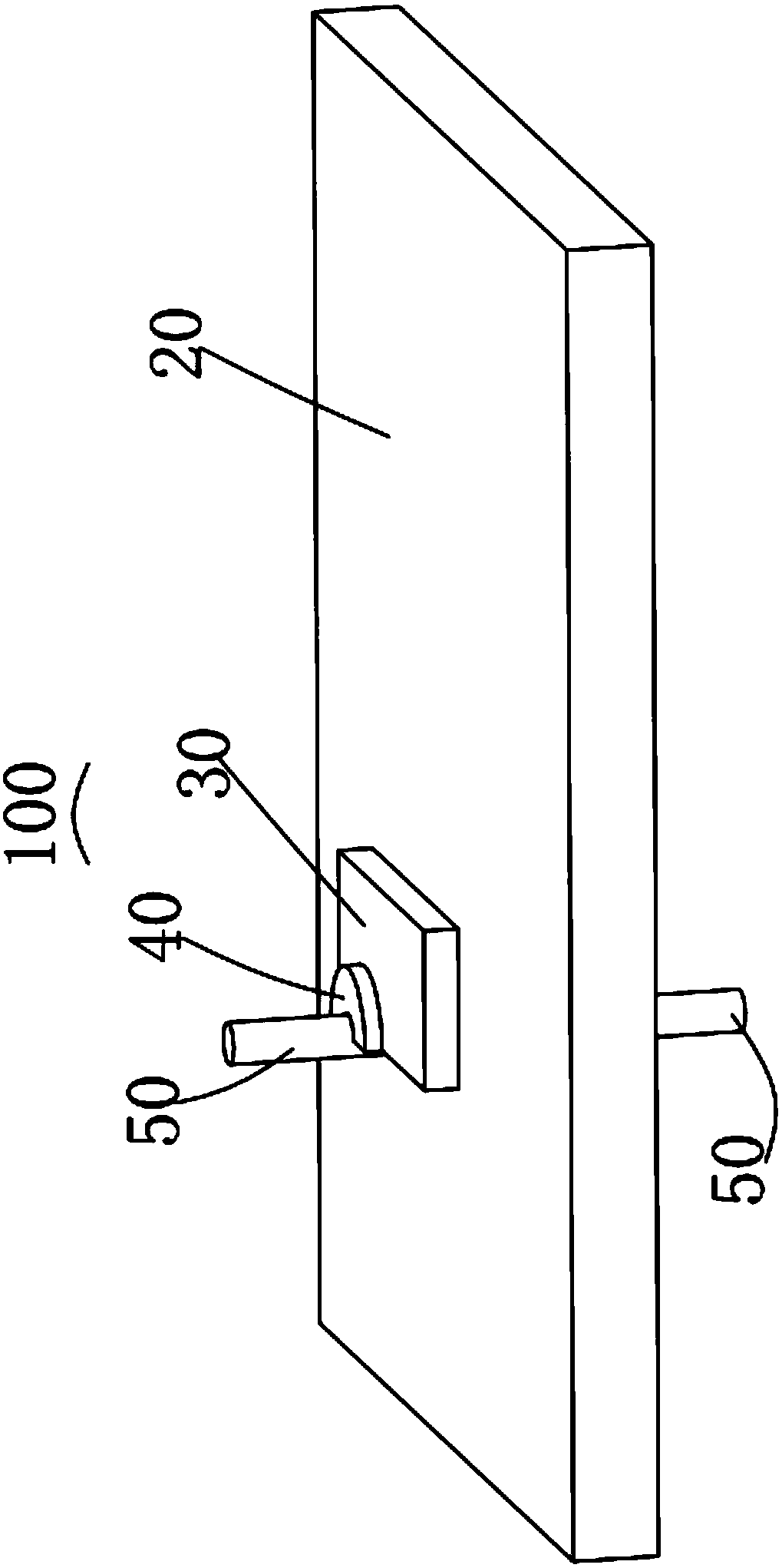

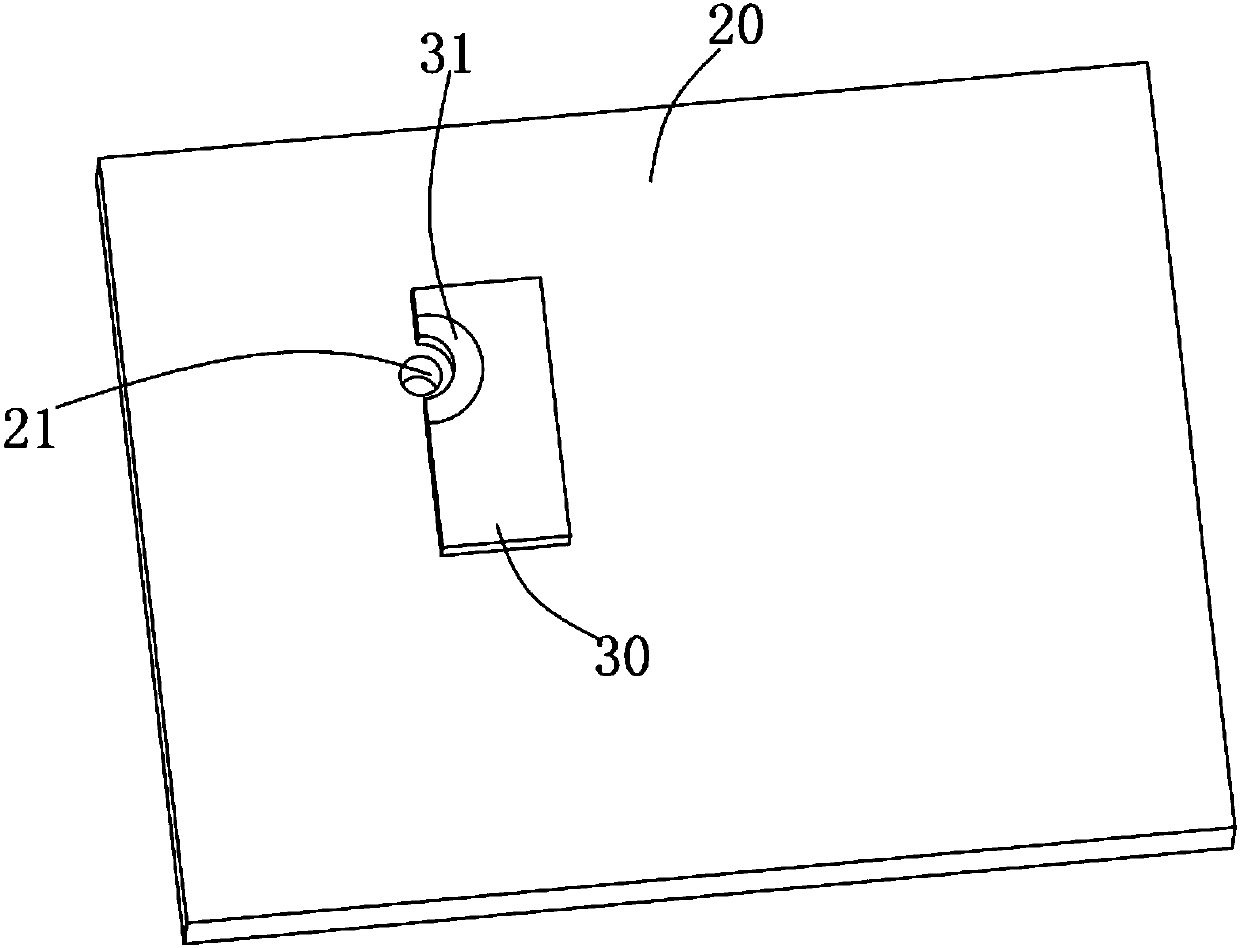

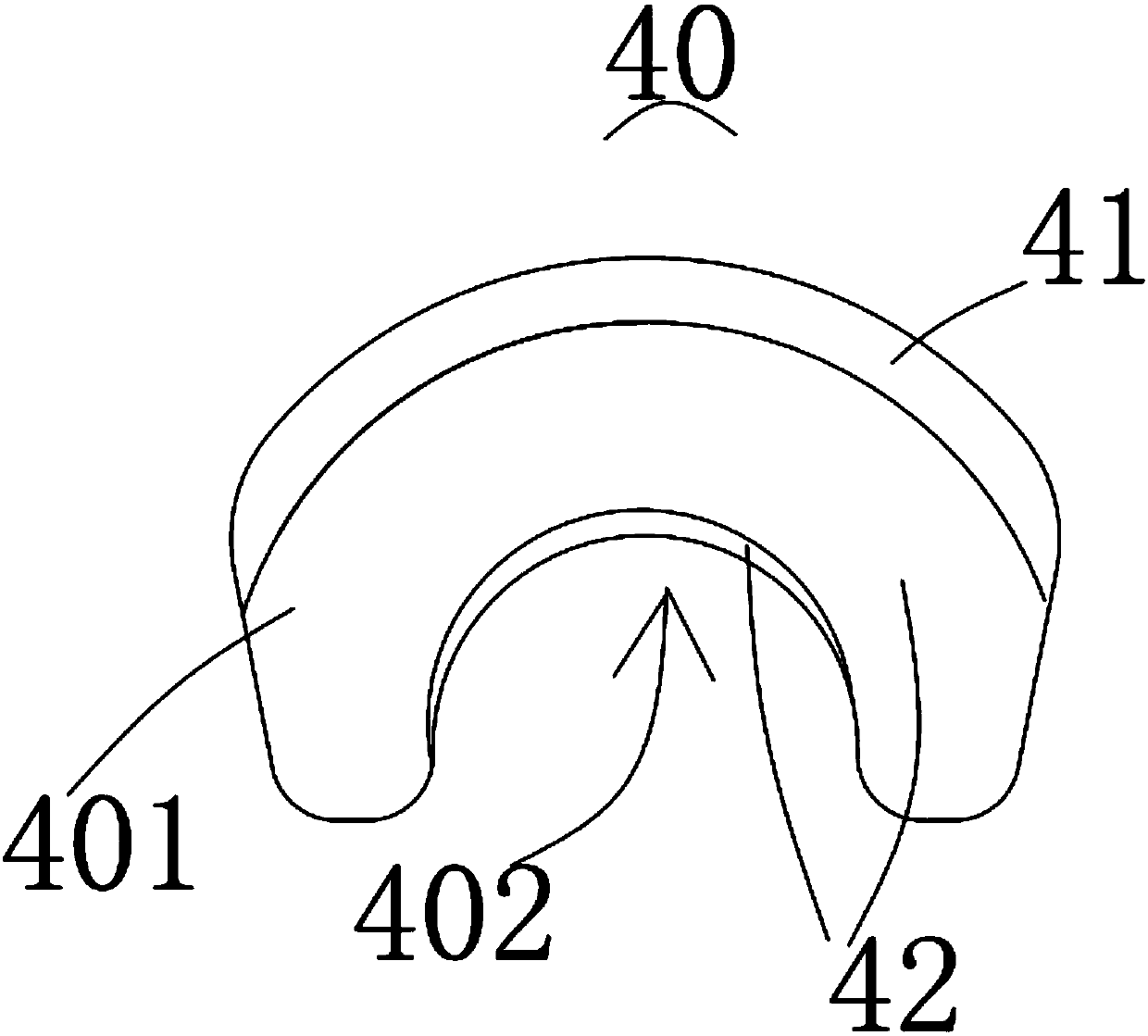

[0024] Such as figure 1 , figure 2 and image 3 As shown, the thick film hybrid circuit pin connection structure 100 includes a substrate 20, an integrated circuit part 30, a connecting part 40 and a pin 50; the integrated circuit part 30 is fixed on the substrate 20, and the substrate 20 is an insulating material and is used to support the integrated The circuit part 30; it is necessary to realize the electrical connection and relative fixed connection between the integrated circuit part 30 and the pin 50; the connecting part 40 is a conductive material, and the thermal expansion coefficient of the connecting part 40 is consistent with the pin 50, thereby preventing the connecting part 40 from being deformed by heat. Unstable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com