Mirror surface cleaning device of monitoring camera

A technology for monitoring cameras and cleaning devices, applied in the field of camera cleaning, can solve the problems of poor mirror cleaning effect and the inability of brushes to maintain the fit effect, etc., and achieve the effect of mirror cleaning and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

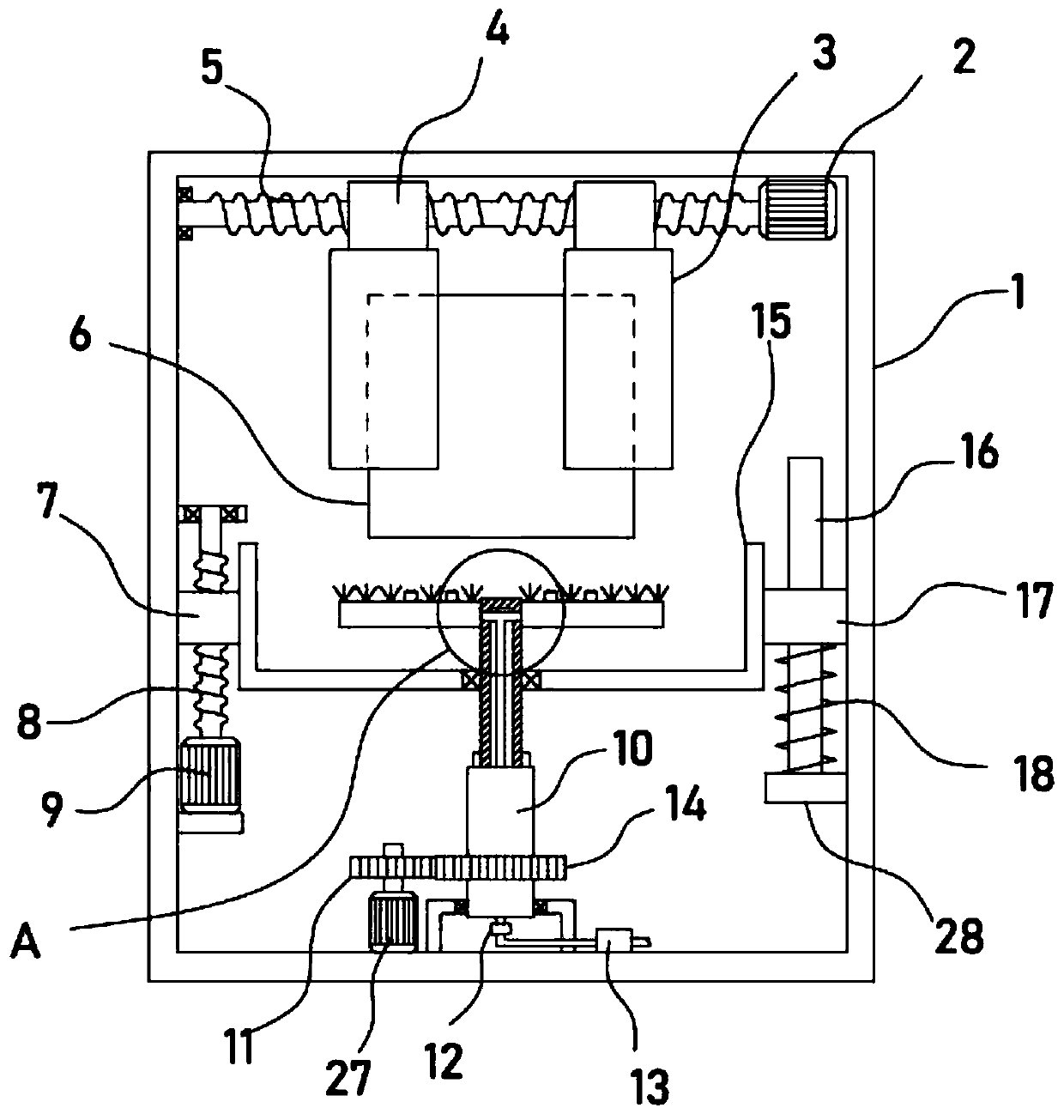

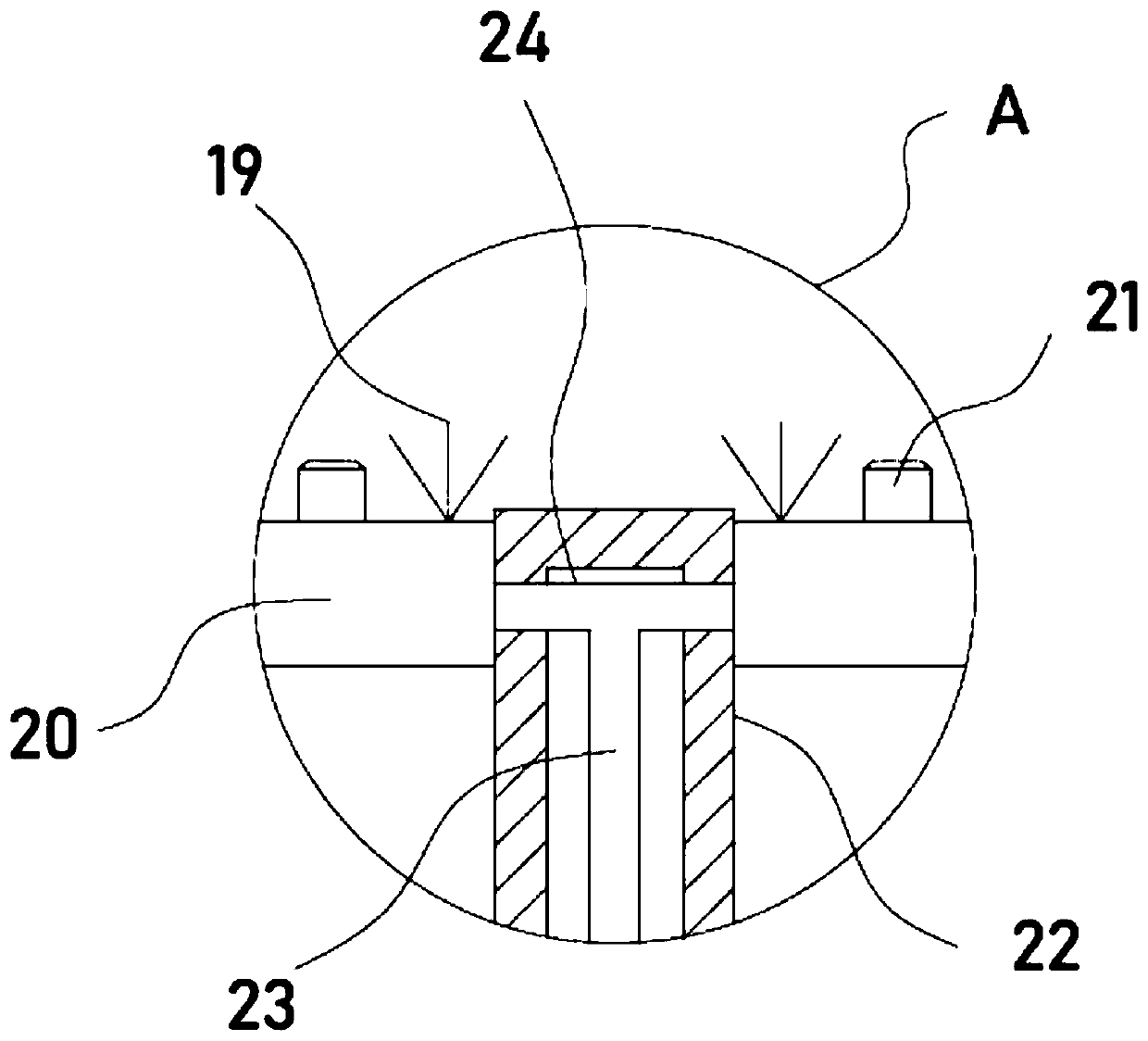

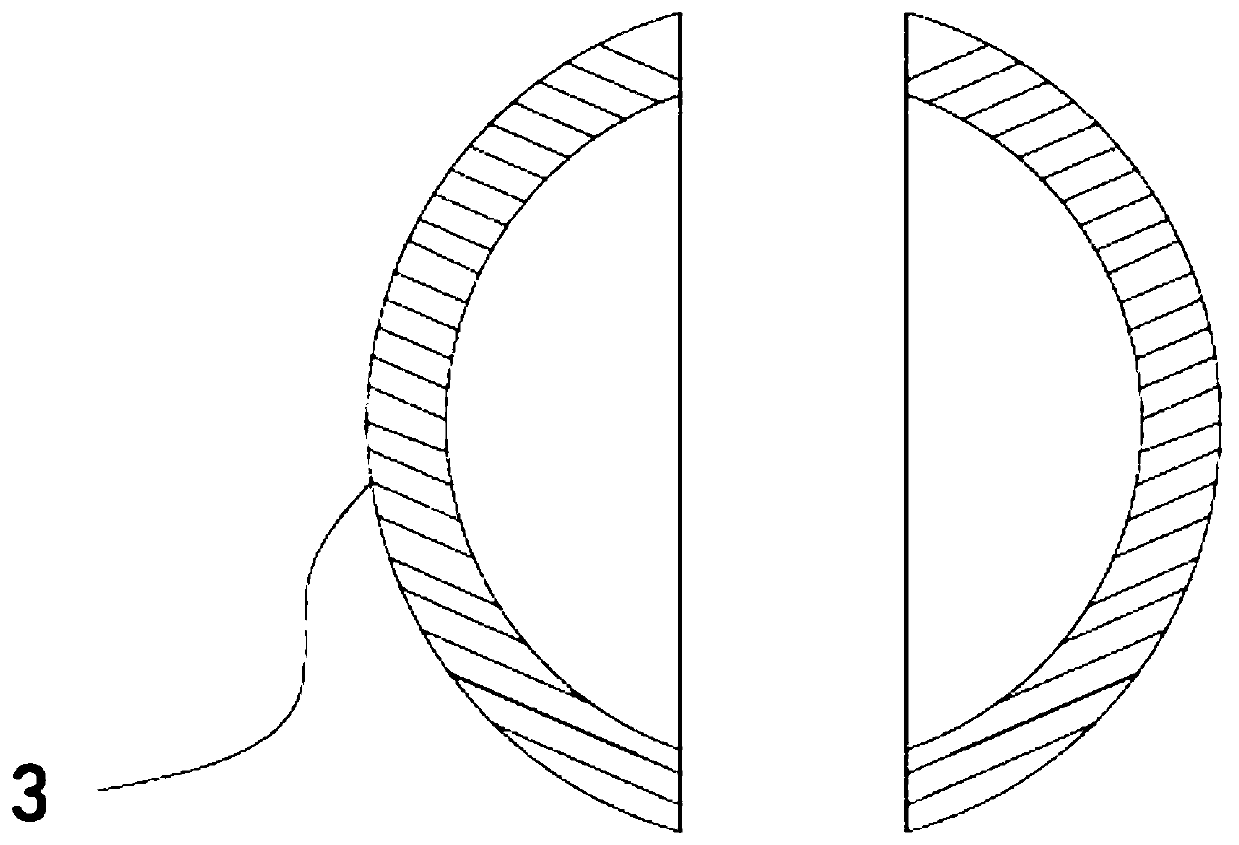

[0023] see Figure 1-5 , a monitoring camera mirror cleaning device, comprising a housing 1, the housing 1 is provided with a water tank 15 driven and connected by a lifting mechanism, the center of the water tank 15 is sealed and pivotally connected with a telescopic tube 22, and the upper side wall of the telescopic tube 22 is fixedly installed with symmetrical Two cleaning components are provided, and the clamping component for clamping the camera 6 is provided directly above the cleaning component through the transmission connection of the adjustment mechanism. 22 is extended with a water delivery main pipe 23 connected to an external water source, and the water delivery main pipe 23 is connected with several upwardly arranged nozzles 21 .

[0024] When cleaning the mirror surface of the camera 6, the camera 6 is clamped and fixed by the clamping assembly, one end of the mirror surface of the camera 6 is vertically downward, and the rotation of the telescopic tube 22 is re...

Embodiment 2

[0028] In order to improve the full cleaning effect of the device on the mirror surface of the camera 6, on the basis of Embodiment 1, the rotating mechanism includes a servo motor III27, and the output shaft of the servo motor III27 is driven to connect the outer surface and is sleeved with a drive sleeve fixed with a pinion gear 14. 10. The inner wall of the transmission sleeve 10 is axially provided with a card slot 26 , and the side wall of the telescopic tube 22 is fixed with a card bar 25 which slides and engages with the card slot 26 .

[0029] Through the above settings, the servo motor III27 is used to drive the main gear 11 to rotate, and the main gear 11 drives the pinion gear 14 meshed with it to rotate. At this time, the pinion gear 14 drives the transmission sleeve 10 to rotate, and the clip bar 25 is engaged with the clip slot 26. , to realize that the telescopic tube 22 drives the rotating plate 20 to rotate, and then realizes the rotating cleaning effect of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap