Cold Correction Method for Deformation of Aluminum Alloy Longitudinal Beam Parts

A technology of aluminum alloy and parts, which is applied in aircraft parts, transportation and packaging, etc., can solve the problems that cannot be used to correct the shape of stringer parts, etc., and achieve the effect of wide application range, low forming cost and large shaping ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0041] Such as Figure 5 As shown in the figure, this part is a key part for connecting fuselage panels, floor beams and docking of different fuselage barrel sections. The structure of the part in the length and width directions is asymmetrical, and the shape of the part is distorted and deformed after machining. The out-of-tolerance rate exceeds 80%, which seriously affects the manufacturing cost and project cycle. The shape correction of this part cannot be completed by the traditional cold correction method.

[0042] A cold correction method for deformation of aluminum alloy longitudinal beam parts, comprising the following steps:

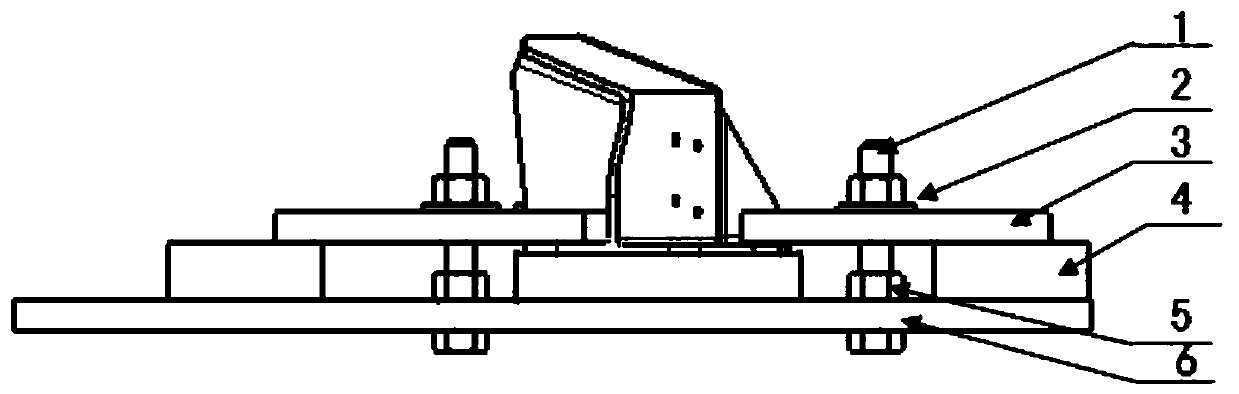

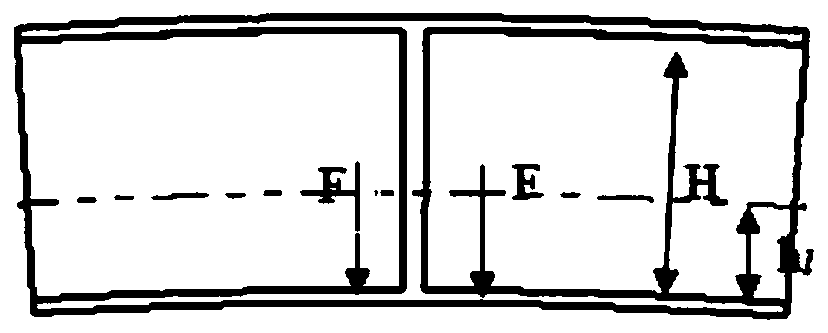

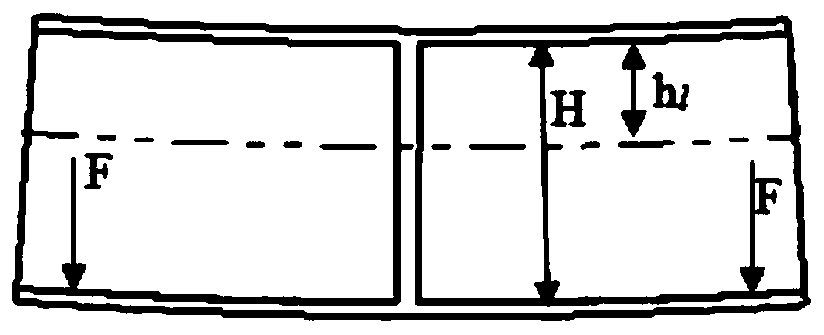

[0043] The first step is to design and manufacture the appearance inspection tooling by means of assembly. The structure of the tooling is as follows: Figure 4 . The tooling is composed of a checker 7, a limit b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com