Driving mechanism for flapping rotor aircraft

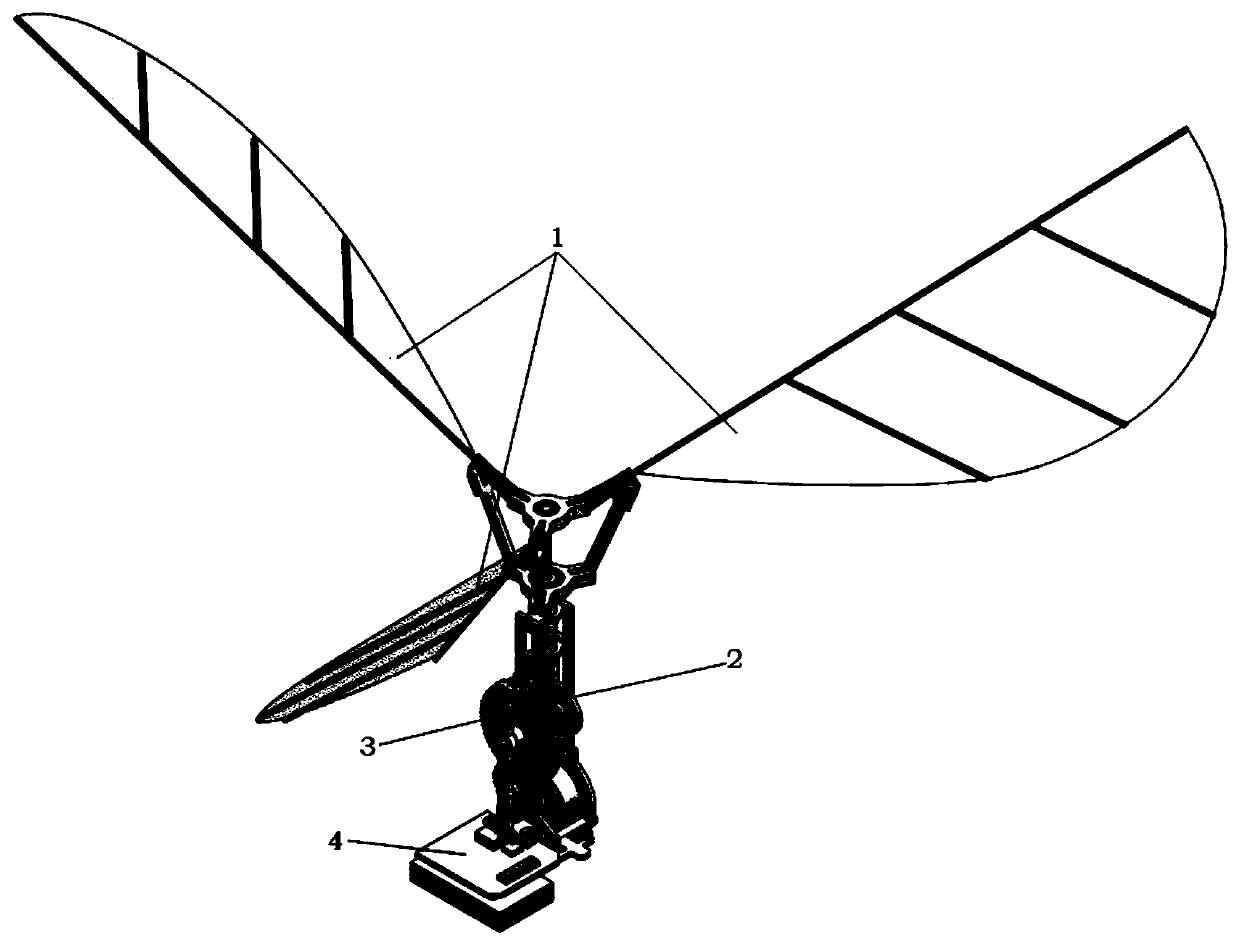

A driving mechanism and aircraft technology, applied to aircraft, helicopters, motor vehicles, etc., can solve problems such as poor stability and unsatisfactory transmission effect, achieve high integration of parts, large lift, and overcome insufficient rigidity of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

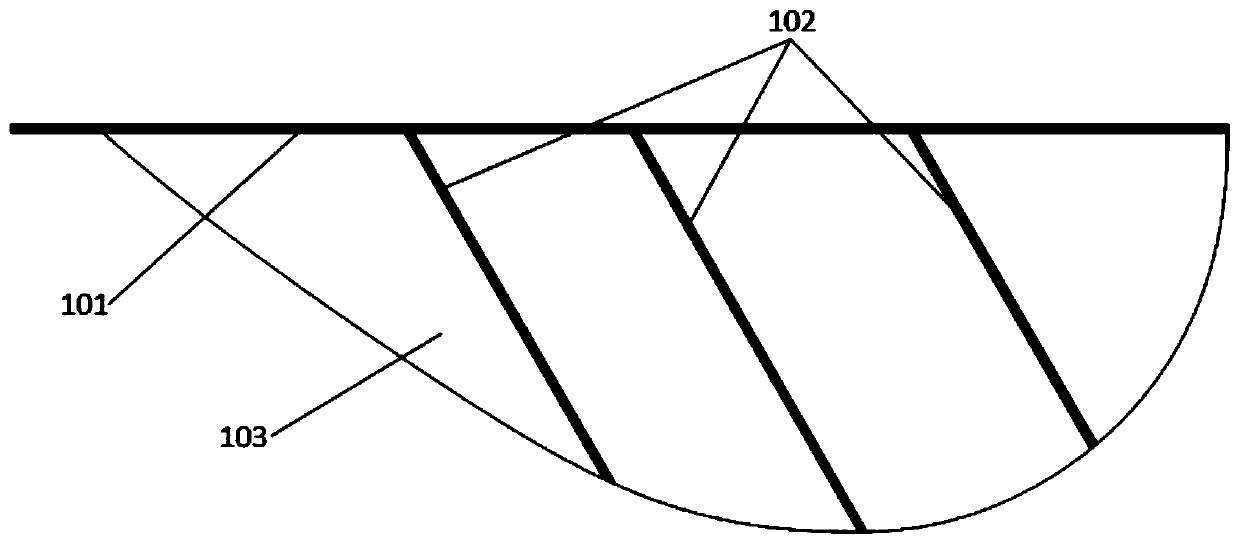

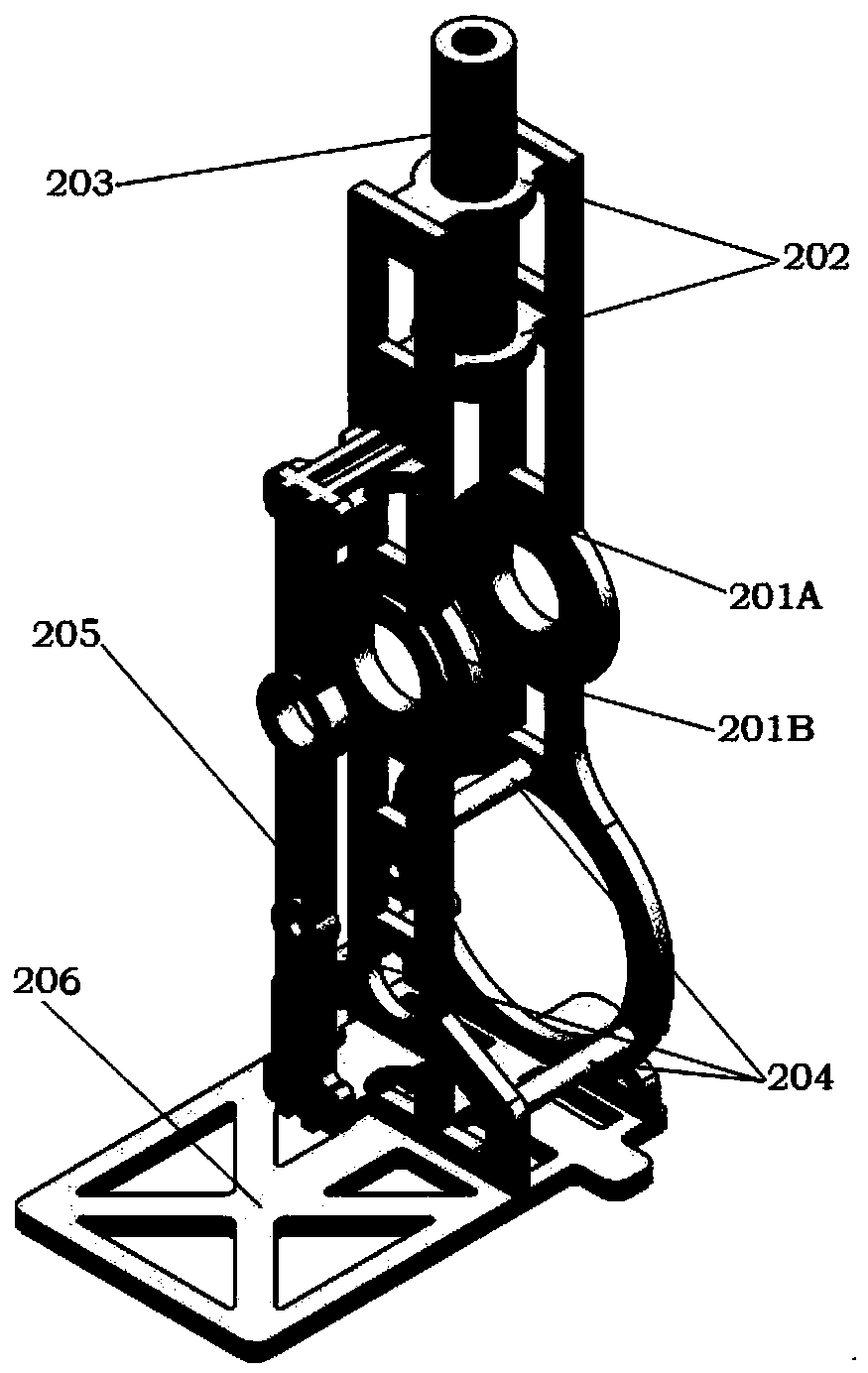

[0051] This embodiment provides the size parameters of a novel drive mechanism for a flapping rotorcraft. In this embodiment, the span of a single aircraft is 130mm, the height of the power unit (not including the airfoil) is 77.4 to 89.4mm, the miniature brushless motor 403 is a 4000kv version AP03 miniature outer rotor brushless motor, and the modulus of all gears is 0.3. Among them, the motor gear 303 has 9 teeth, the double-layer gear 302 has 12 and 36 teeth, the large gear 301 has 70 teeth, the working length of the airfoil rod is 21mm, the working length of the rocker arm 314 is 6mm, and the steering gear model is Pingzheng PZ-15320 Ultra-miniature low-voltage digital steering gear.

[0052] It has been verified by simulation that the novel driving mechanism of the present invention for flapping rotorcraft can realize normal flapping and rotating motion of the wing surface, with a flapping range of about ±35° and a maximum lift of about 38g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com