Textile yarn waxing device

A yarn and equipment technology, applied in the field of waxing equipment, can solve problems such as troublesome and low work efficiency, and achieve the effect of simple operation and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

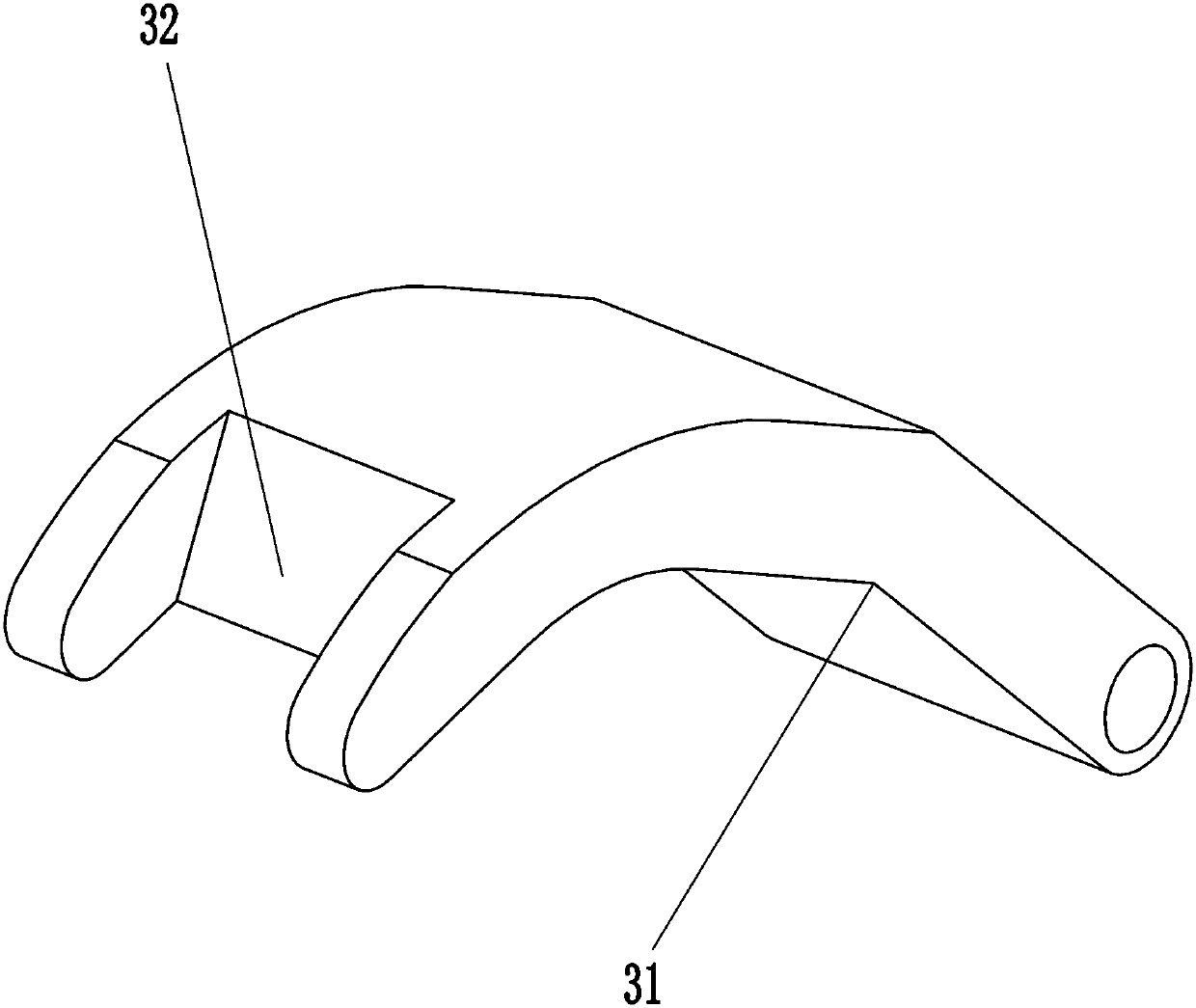

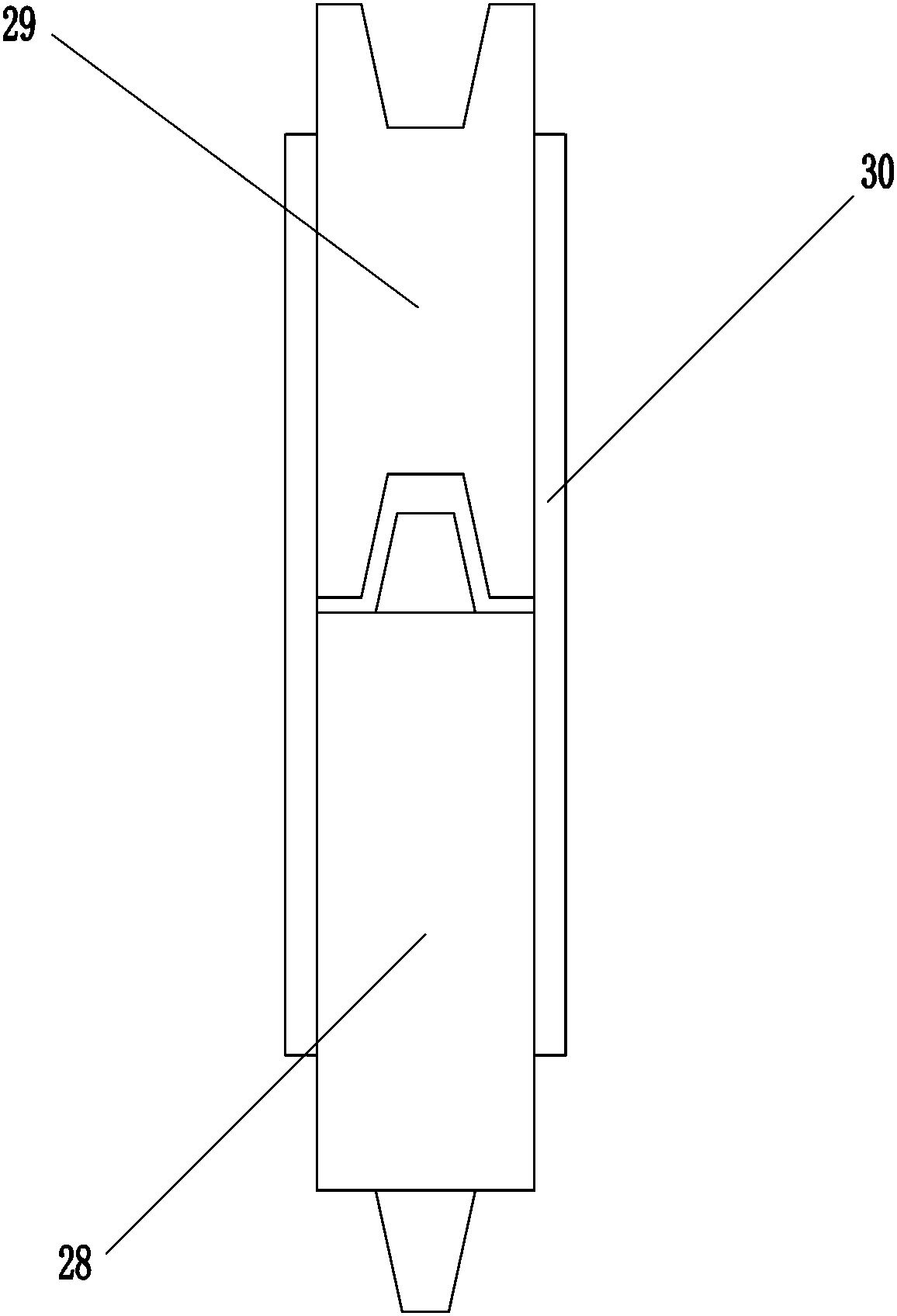

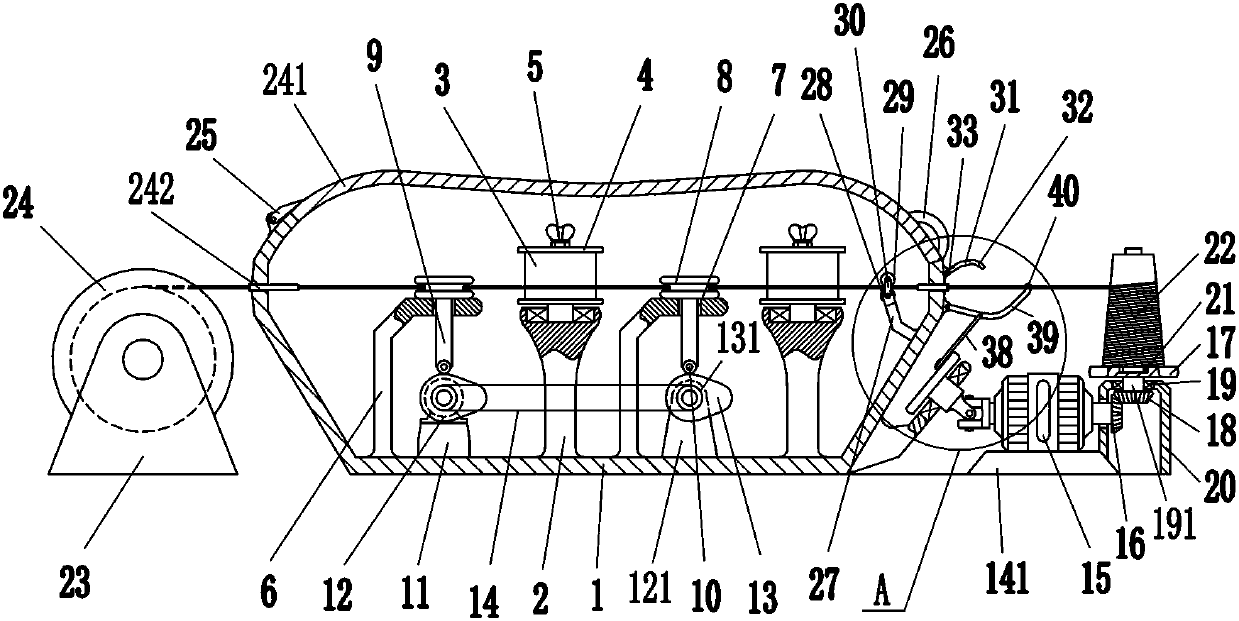

[0016] A kind of textile yarn waxing equipment, such as figure 1 As shown, it includes box body 1, support column 2, cylinder water-soluble wax 3, end cap 4, butterfly nut 5, L-shaped rod 6, sheave 8, ejector rod 9, small pulley 10, first support 11. Ordinary motor 12, support plate 121, cam 13, pulley 131, ordinary belt 14, trapezoidal plate 141, double-head drive motor 15, first bevel gear 16, first turntable 17, second bevel gear 18, deep Groove ball bearing 19, rotating shaft 191, protective shell 20, finished product reel 22, second support 23, raw material reel 24, shell 241, moldable hose 242, connection block 25 and handle 26, inside the box body 1 A support column 2 is fixedly connected in the middle of the bottom, and a support column 2 is also fixedly connected to the right side of the bottom of the box body 1. The box body 1 is connected to the support column 2 by means of bolt connection. Cylinder water soluble wax 3, the top of cylinder water soluble wax 3 is pr...

Embodiment 2

[0018] A kind of textile yarn waxing equipment, such as Figure 1-2As shown, it includes box body 1, support column 2, cylinder water-soluble wax 3, end cap 4, butterfly nut 5, L-shaped rod 6, sheave 8, ejector rod 9, small pulley 10, first support 11. Ordinary motor 12, support plate 121, cam 13, pulley 131, ordinary belt 14, trapezoidal plate 141, double-head drive motor 15, first bevel gear 16, first turntable 17, second bevel gear 18, deep Groove ball bearing 19, rotating shaft 191, protective shell 20, finished product reel 22, second support 23, raw material reel 24, shell 241, moldable hose 242, connection block 25 and handle 26, inside the box body 1 A support column 2 is fixedly connected to the middle of the bottom, and a support column 2 is also fixedly connected to the right side of the inner bottom of the box body 1. The tops of the two support columns 2 are rotatably installed with a cylinder of water-soluble wax 3, and the top of the cylinder of water-soluble wa...

Embodiment 3

[0021] A kind of textile yarn waxing equipment, such as Figure 1-4 As shown, it includes box body 1, support column 2, cylinder water-soluble wax 3, end cap 4, butterfly nut 5, L-shaped rod 6, sheave 8, ejector rod 9, small pulley 10, first support 11. Ordinary motor 12, support plate 121, cam 13, pulley 131, ordinary belt 14, trapezoidal plate 141, double-head drive motor 15, first bevel gear 16, first turntable 17, second bevel gear 18, deep Groove ball bearing 19, rotating shaft 191, protective shell 20, finished product reel 22, second support 23, raw material reel 24, shell 241, moldable hose 242, connection block 25 and handle 26, inside the box body 1 A support column 2 is fixedly connected to the middle of the bottom, and a support column 2 is also fixedly connected to the right side of the inner bottom of the box body 1. The tops of the two support columns 2 are rotatably installed with a cylinder of water-soluble wax 3, and the top of the cylinder of water-soluble w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com