A Longitudinal Polishing Machine for Rod Samples

A polishing machine, longitudinal technology, used in grinding/polishing equipment, grinding machine parts, manufacturing tools, etc., can solve problems such as easy to hurt hands, low efficiency, inability to correctly characterize the performance of metal materials, and achieve polishing quality. The effect of improving, uniform force and avoiding edges and corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

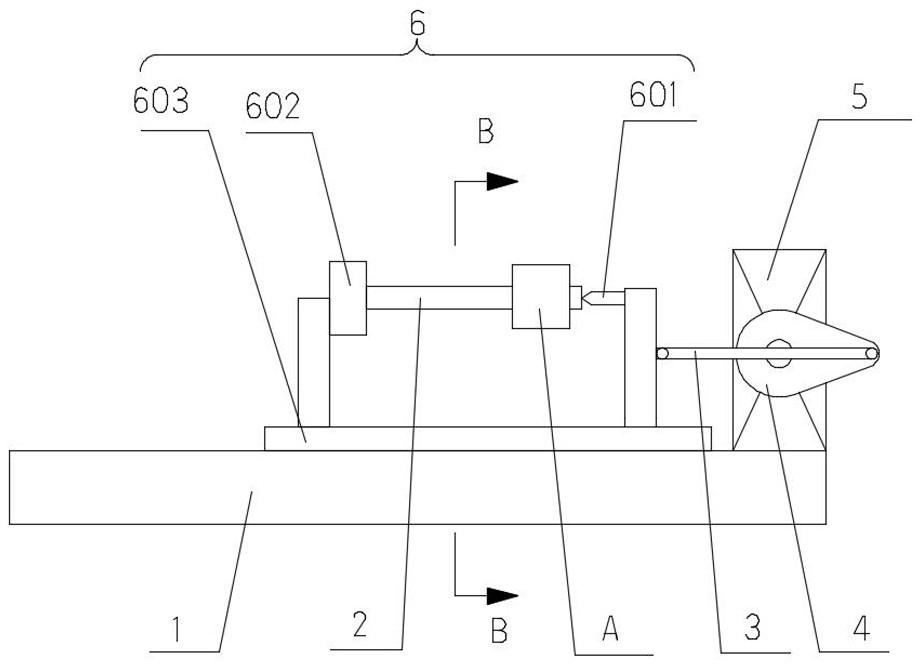

[0045] Such as figure 1 As shown, a longitudinal polishing machine for a rod-shaped sample 2 in this embodiment, the main structure is a horizontal base 1 and a clamping device 6 and a polishing device A arranged on the horizontal base 1 .

[0046] The horizontal base 1 is fixed on a firm ground or a workbench, and its upper edge is a flat horizontal plane.

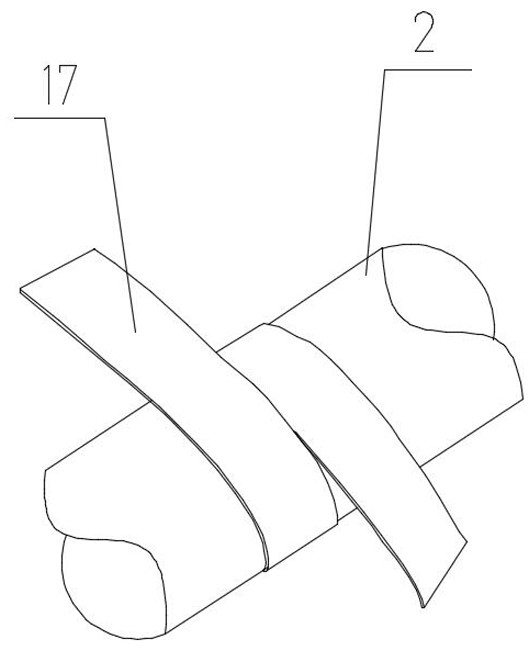

[0047] The clamping device 6 is used to clamp and fix the sample 2, and can carry the sample 2 along the figure 1 The horizontal left and right linear directions in the middle slide reciprocally on the horizontal base 1. The clamping device 6 includes a slide plate 603 slidably set on the horizontal base 1 , a chuck 602 set at one end of the slide plate 603 , and a tip 601 set at the other end of the slide plate 603 . The sliding plate 603 slides and fits with the upper edge of the horizontal base 1 through two wire rails. A clamping position for fixing the sample 2 is formed between the chuck 602 and the tip 601 , and...

Embodiment 2

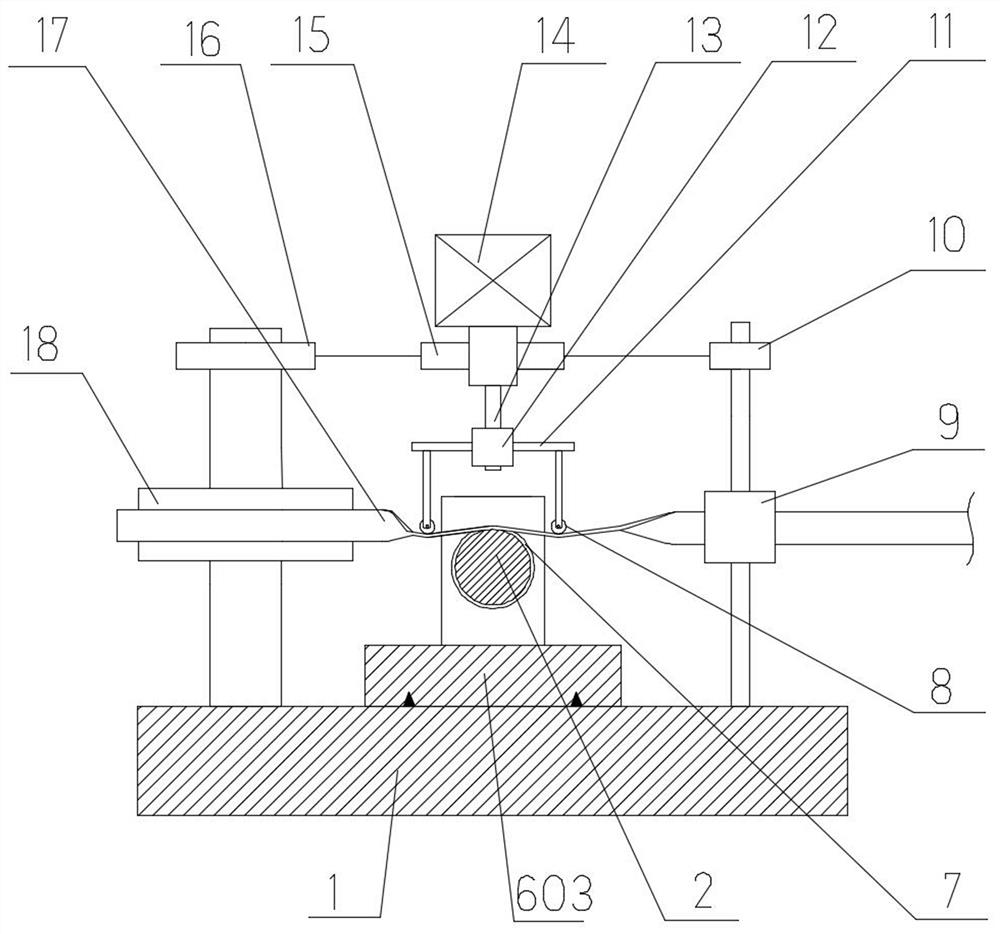

[0057] Such as Figure 7 As shown, the main structure of this embodiment is the same as that of Embodiment 1, and both include a horizontal base 1 and a clamping device 6 and a polishing device A arranged on the horizontal base 1. The structures of the horizontal base 1, the clamping device 6 and the device are also approximate. The main difference between this embodiment and embodiment 1 is that the second servo motor 5 is omitted in the present embodiment, and the pressing and relaxing process of the pressing wheel 8 and the update of the polishing abrasive belt 17 are not only driven by the first servo motor 14, And the reciprocating sliding of the clamping device 6 is driven by the first servo motor 14, which further reduces the production cost, and saves the difficulty of cooperation between the first servo motor 14 and the second servo motor 5 and the first servo motor 14 and the second servo motor 5 in Embodiment 1. The deviation generated during the matching process o...

Embodiment 3

[0066] Such as Figure 11 As shown, the structure of Embodiment 2 of this embodiment is basically the same, and only one first servo motor 14 not only drives the pressing and relaxing process of the pressing wheel 8 and the update of the polishing abrasive belt 17, but also drives the clamping process by the first servo motor 14. The reciprocating sliding of the holding device 6. The difference between this embodiment and Embodiment 2 is that the first servo motor 14 drives the clamping device 6 to reciprocate in different ways:

[0067] Such as Figure 12 As shown, the output shaft of the first servo motor 14 is provided with a sixth gear 35 for driving the clamping device 6 to reciprocate and slide, and the sixth gear 35 is a sector gear. One side of the slide plate 603 is provided with a third rack 34 that can be meshed with the sixth gear 35, and one end of the slide plate 603 is also provided with a spring for the slide plate 603 to rebound after the third rack 34 break...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com