Concrete laying and vibrating integrated device used for road construction

A technology for road construction and concrete, which is applied in the field of concrete laying and vibrating integrated device for road construction, which can solve the problems of long construction time and lack of laying function, and achieve the effect of preventing condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

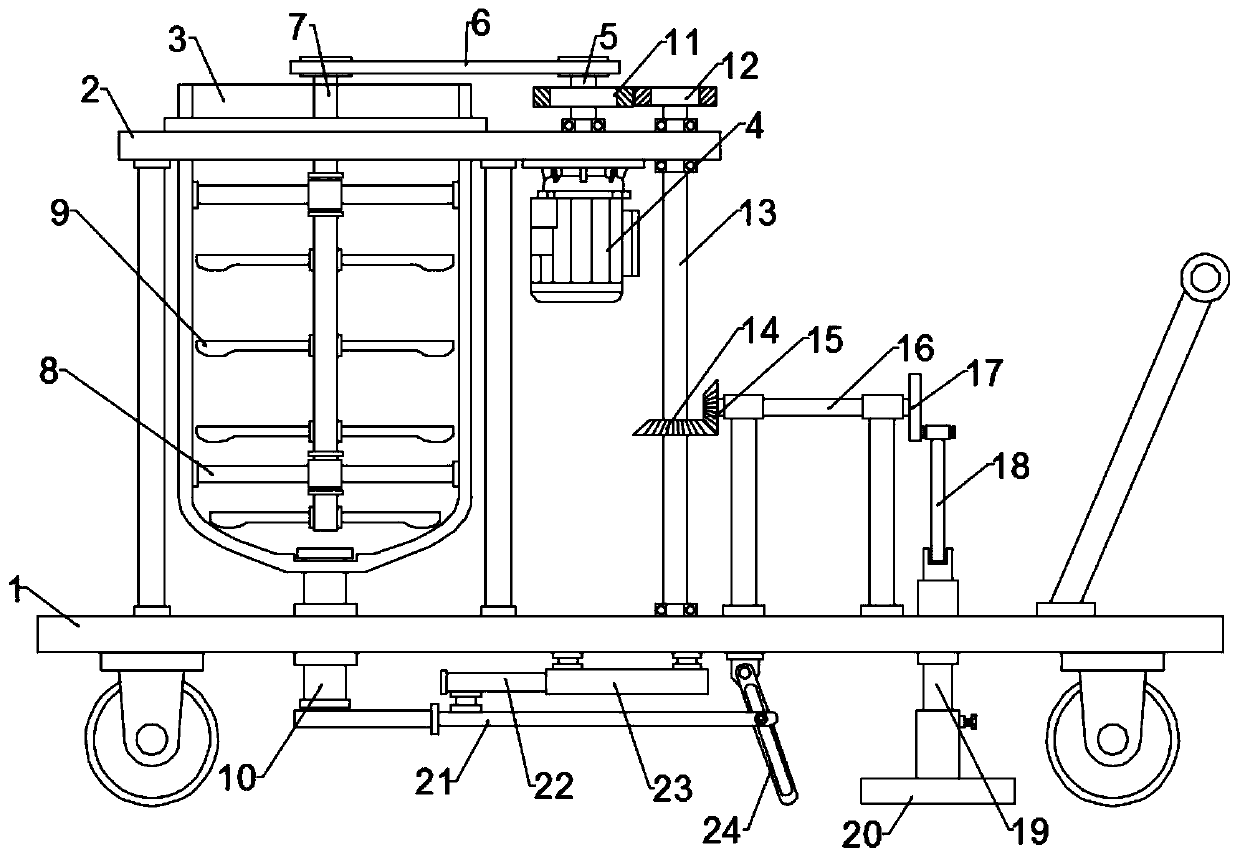

[0022] see Figure 1~3 , in an embodiment of the present invention, a concrete laying and vibrating integrated device for road construction, comprising a bottom plate 1, a top plate 2 fixed on the upper part of the front of the bottom plate 1 through a bracket, and used for feeding the material in the bucket 3 installed on the top plate 2 Mixing components for mixing and vibrating components for compacting the laid concrete beach;

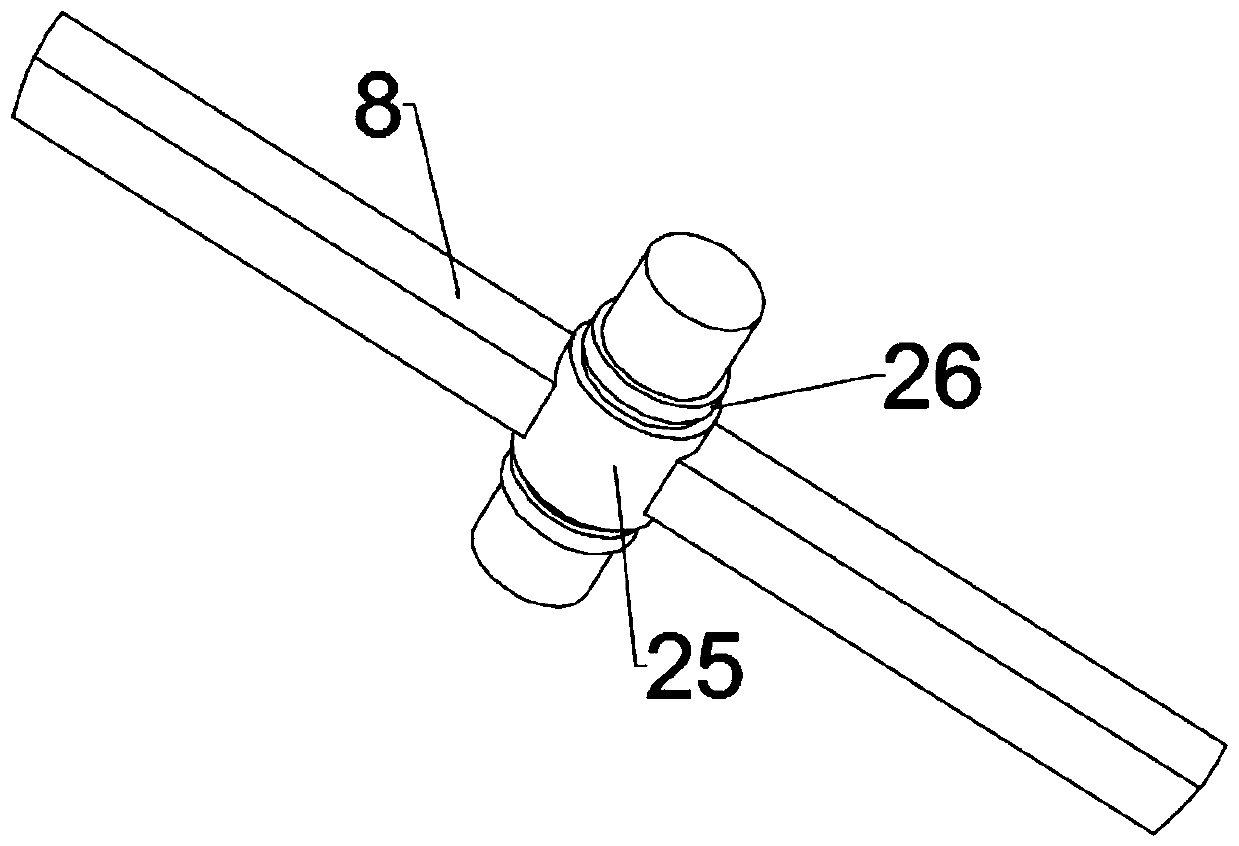

[0023] Specifically, the bottom of the bucket 3 is connected with a discharge pipe 10 for discharging concrete. The discharge pipe 10 passes through the bottom plate 1 and is fixedly connected with it. The flange on one side of the top plate 2 is equipped with a drive motor 4. The output end is connected to the output shaft 5, the output shaft 5 passes through the top plate 2 and is connected with the bearing, and the driving motor 4 is energized to drive the output shaft 5 to rotate; the stirring assembly includes a stirring shaft 7 connected to t...

Embodiment 2

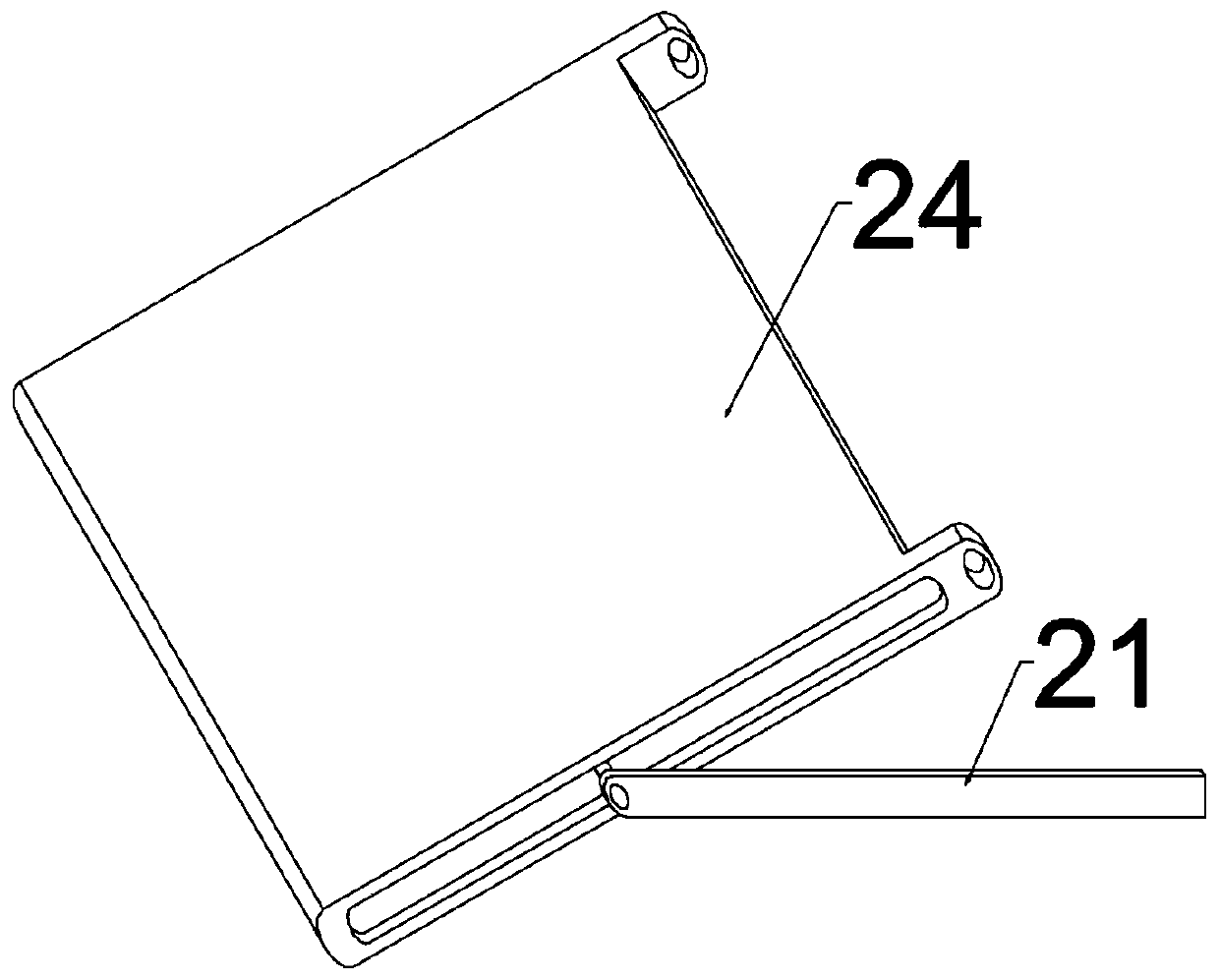

[0027] In order to control the discharge of concrete, the present application provides yet another embodiment. In this embodiment, a concrete laying and vibrating integrated device for road construction also includes a displacement adjustment mechanism. Specifically, the displacement adjustment mechanism includes The adjusting plate 21 which is arranged at the lower opening of the discharge pipe 10 and fits it and the pneumatic assembly fixedly connected to the adjusting plate 21, the pneumatic assembly is composed of a cylinder 23 installed under the bottom plate 1 and a piston rod 22 slidingly connected to the cylinder 23 , the adjustment plate 21 is fixed at the end of the piston rod 22, and the piston rod 22 is driven to slide by the cylinder 23 so as to drive the adjustment plate 21 to move, and the opening size of the lower opening of the discharge pipe 10 is controlled, and finally the concrete displacement is realized. control.

[0028] In order to flatten the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com