Multipurpose heat pump curing barn

A multi-purpose heat pump technology, applied in application, heating devices, lighting and heating equipment, etc., can solve the problems that air energy heat pumps cannot make full use of light energy and are only suitable for tobacco leaves, etc., so as to increase the residence time, improve absorption, prolong The effect of the flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

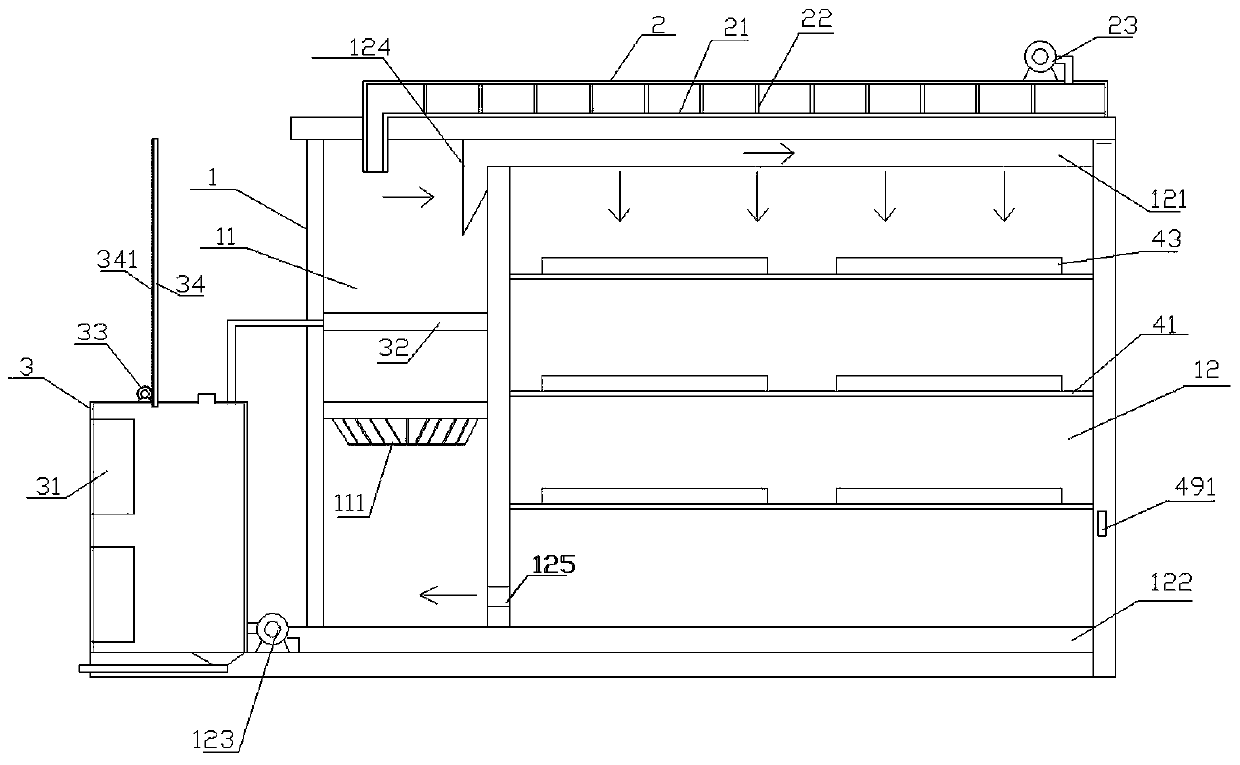

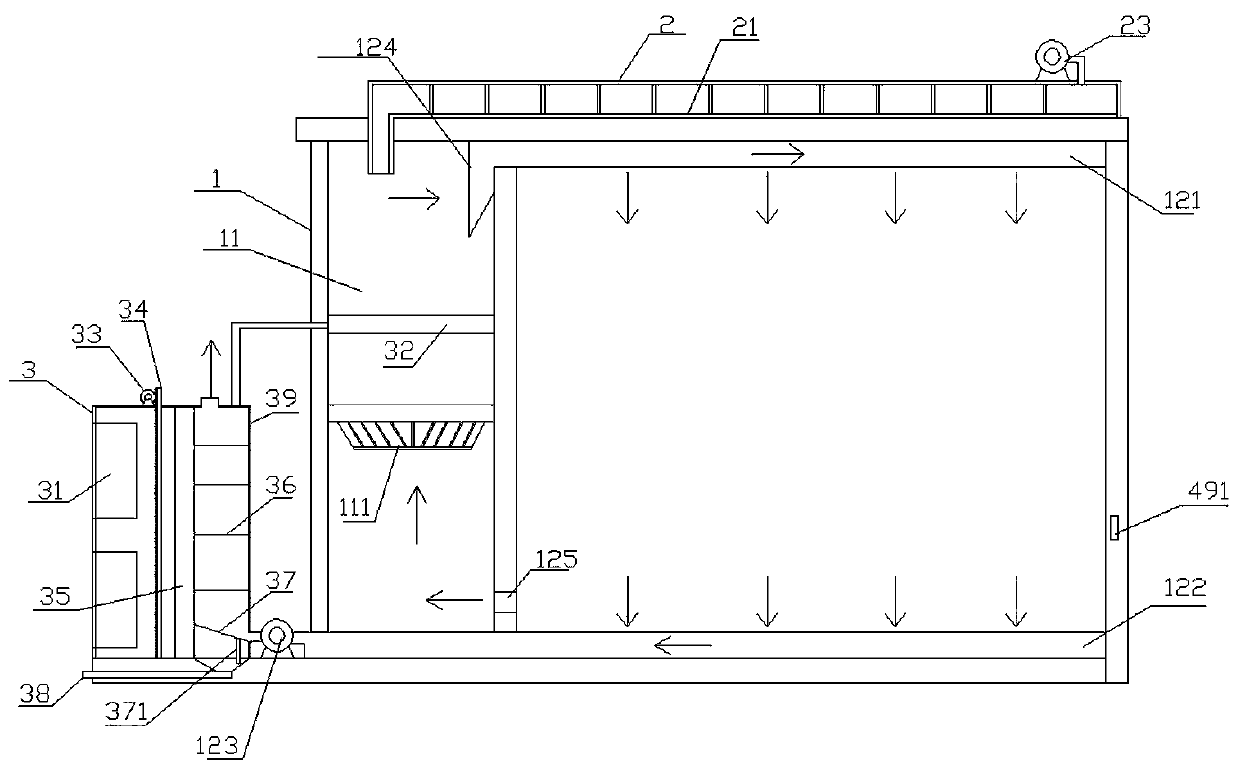

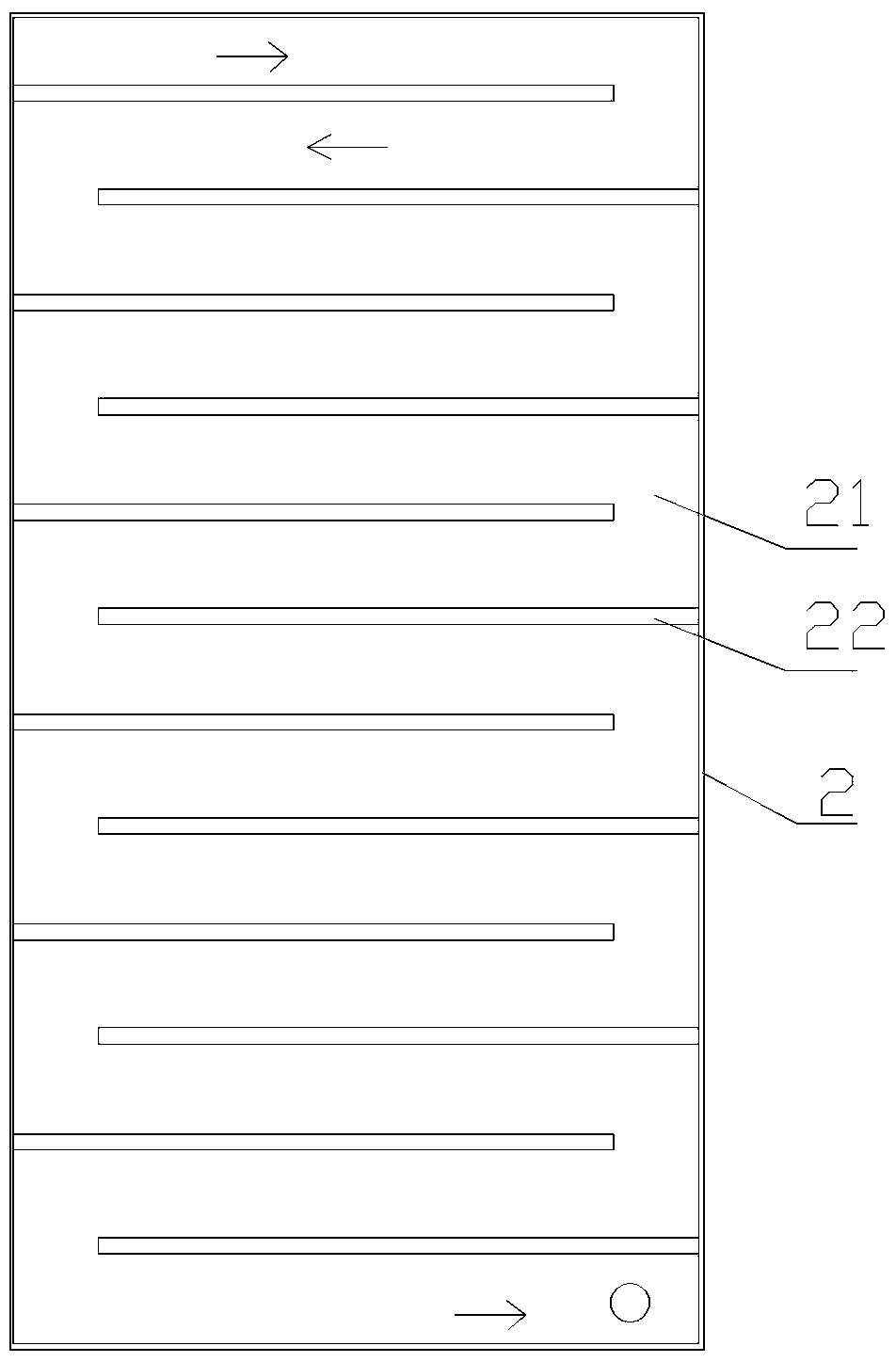

Method used

Image

Examples

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that the following technical means are added, the end of the air supply pipe is provided with a first temperature monitor, and the solar hot air box is provided with a second temperature monitor. The second temperature monitor is connected with the external temperature value display device for data connection.

[0050] This embodiment monitors the temperature in the solar hot air box by the second temperature monitor, if the temperature in the solar hot air box is lower than the temperature in the hot air chamber, then the staff can stop the blower and only rely on the air source heat pump to provide the heat source; through the first temperature The monitor detects the temperature of the hot air heated by the solar hot air box. If the temperature of the hot air reaches the standard required for baking (that is, the temperature of the solar hot air box must be higher than the temperature in the hot air room), the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com