Flexible acoustoelectric substrate and its preparation method, flexible acoustoelectric device

A flexible substrate, acoustic and electric technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problem of good products Low efficiency, complex process implementation and other issues, to achieve the effect of no etching residue, good etching uniformity, and flexible layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

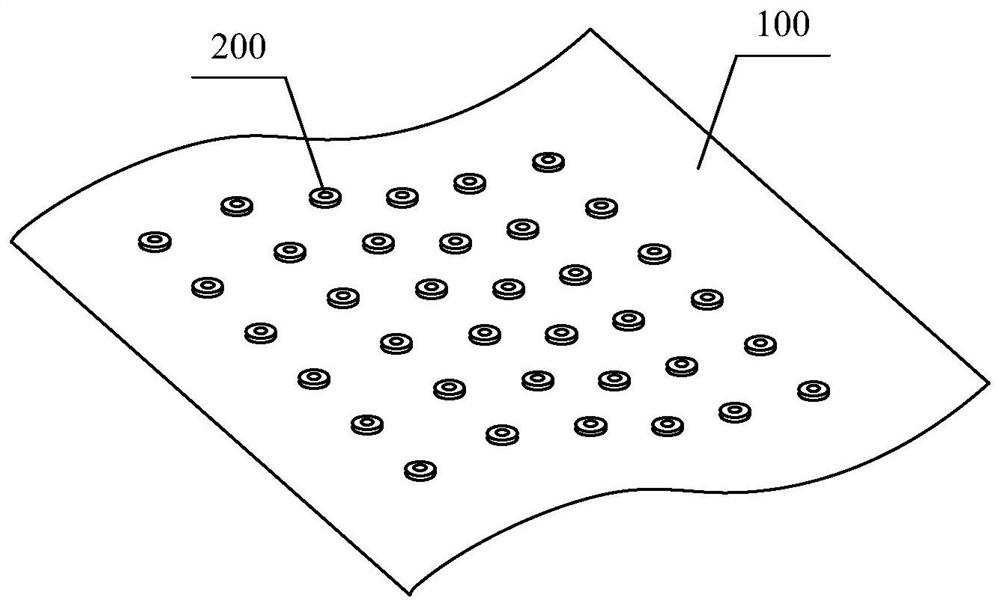

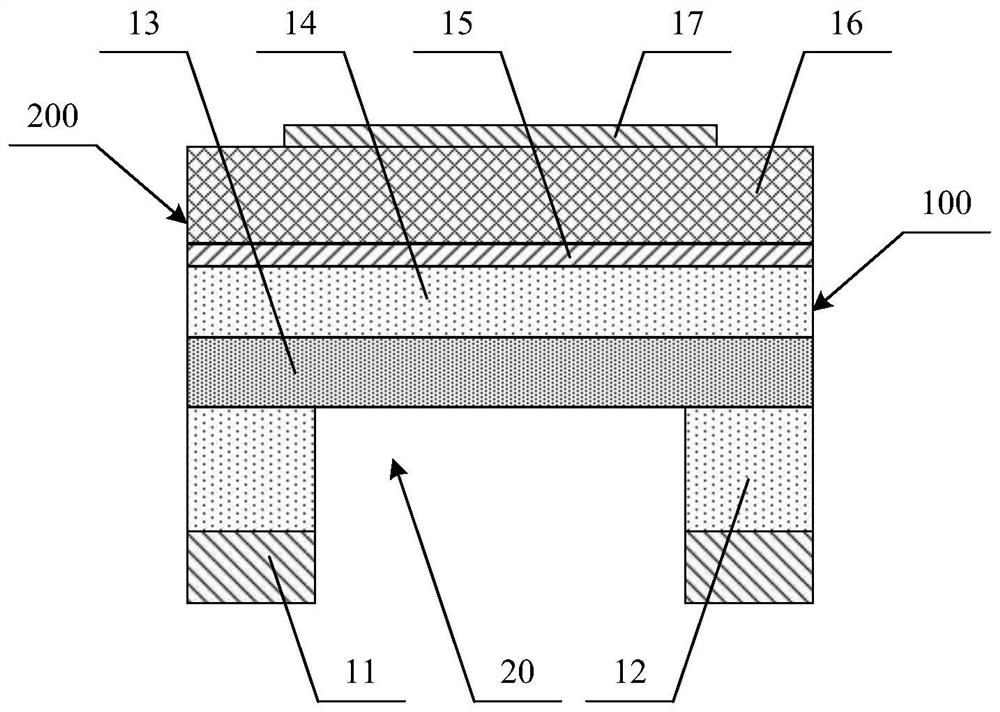

[0079] figure 2 It is a structural schematic diagram of the first embodiment of the flexible acoustic-electric substrate of the present invention, showing a cross-sectional view of a piezoelectric transducer. Such as figure 2 As shown, the main structure of the piezoelectric transducer in this embodiment includes a flexible substrate 100 and a piezoelectric component 200 disposed on the flexible substrate 100 , and the cavity 20 of the piezoelectric transducer is disposed in the flexible substrate 100 . The piezoelectric component 200 includes a lower electrode 15 , a piezoelectric layer 16 and an upper electrode 17 stacked on the surface of the flexible substrate 100 away from the chamber 20 , forming a piezoelectric sandwich structure. The flexible substrate 100 includes a mask layer 11, a second flexible layer 12, a barrier layer 13 and a third flexible layer 14 stacked in sequence. The mask layer 11, the second flexible layer 12 and the barrier layer 13 together form a ...

no. 2 example

[0103] Figure 15 It is a structural schematic diagram of the second embodiment of the flexible acoustic-electric substrate of the present invention, showing a cross-sectional view of a piezoelectric transducer. Such as Figure 15 As shown, the main structure of the piezoelectric transducer in this embodiment includes a flexible substrate 100 and a piezoelectric component 200 disposed on the flexible substrate 100 , and the cavity 20 of the piezoelectric transducer is disposed in the flexible substrate 100 . The piezoelectric component 200 includes a lower electrode 15 , a piezoelectric layer 16 and an upper electrode 17 stacked on the surface of the flexible substrate 100 away from the chamber 20 , forming a piezoelectric sandwich structure. The flexible substrate 100 includes a first flexible film 31, a barrier layer 32 and a second flexible film 32 stacked in sequence. The first flexible film 31 and the barrier layer 32 together form a cavity 20, and the opening of the cav...

no. 3 example

[0111] Based on the technical concept of the foregoing embodiments of the present invention, the embodiments of the present invention also provide a method for preparing a flexible acoustic-electric substrate. The preparation method of the flexible acoustic-electric substrate includes:

[0112] S1, forming a flexible substrate;

[0113] S2. Forming a plurality of piezoelectric components regularly arranged on the flexible substrate;

[0114] S3. Etching the flexible substrate by using inductively coupled plasma to form chambers corresponding to the plurality of piezoelectric components one by one.

[0115] In one embodiment, step S1 includes:

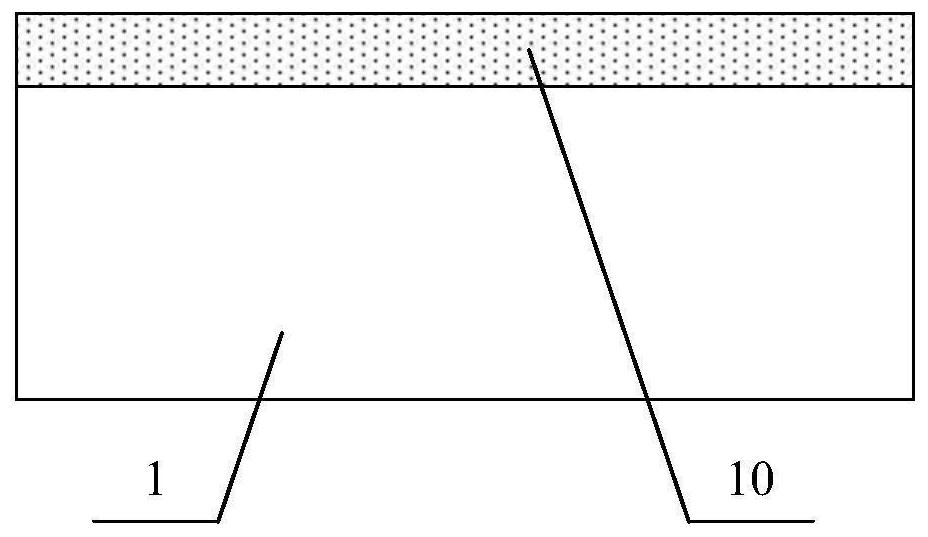

[0116] forming a first flexible layer on a glass carrier;

[0117] forming a mask layer on the first flexible layer, and the mask layer is used as a hard mask for forming a chamber when inductively coupled plasma etching is used;

[0118] The second flexible layer, the barrier layer and the third flexible layer are sequentially form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com