Efficient heat dissipation multilayer circuit board

A multi-layer circuit and circuit board technology, which is applied to the installation of circuit heating devices, printed circuit components, and support structures, can solve the problems of ineffective and difficult heat dissipation of highly integrated circuit boards, and achieve timely and timely heat dissipation. The effect of large area and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

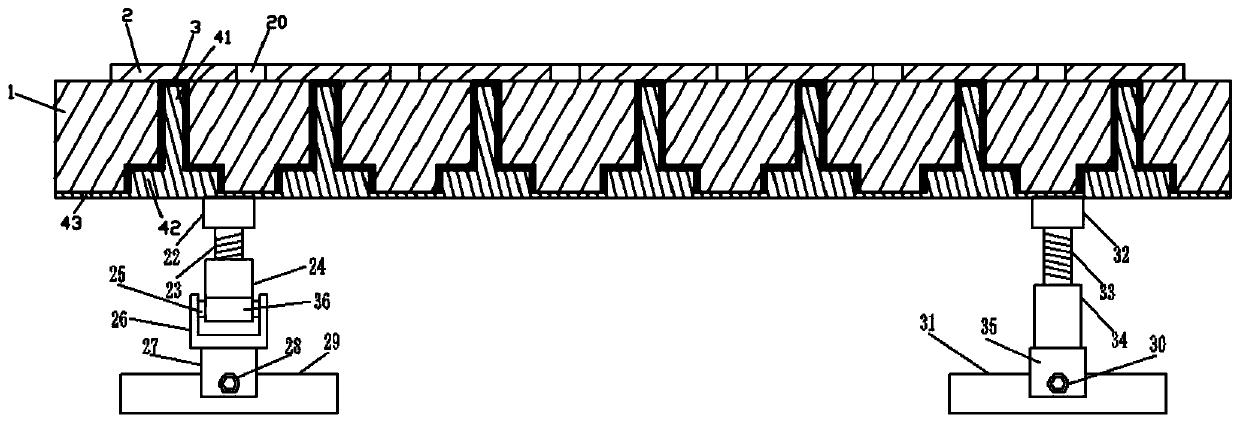

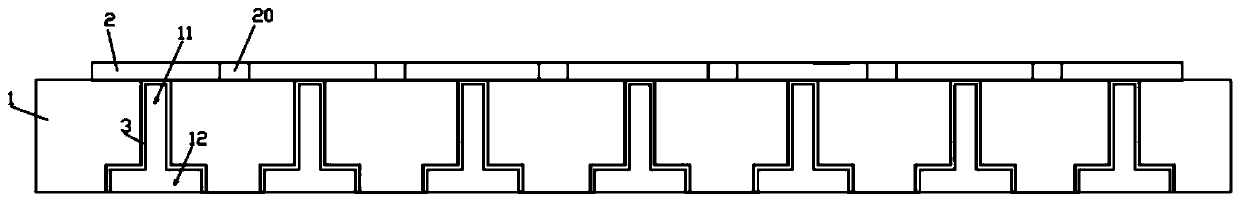

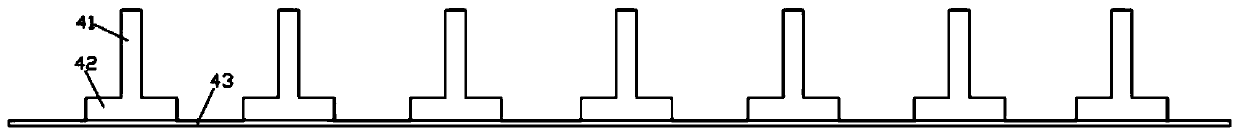

[0027] Such as Figure 1~4 Shown, which shows a specific embodiment of the present invention, such as figure 1 As shown, the present invention is a multi-layer circuit board with high heat dissipation, which includes a circuit board body and an adjustment assembly for adjusting the position of the circuit board body; the adjustment assembly includes a first Bearing 22, the first screw rod 23 is installed on the first bearing, the lower end of the first screw rod is installed in the first nut 24, the first nut is installed on the sleeve 36, the sleeve 36 is installed on the rotating shaft 25, and the rotating shaft is installed on the first wheel On the frame 26, the first wheel frame is installed on the first slide block 27, and the first slide block is installed on the first slide rail 29, and the first slide block is provided with the first bolt 28, and the first bolt connects the first slide block Fixed on the first slide rail; the second bearing is installed on the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com