Wiring body and wiring body assembly

A wiring body and wiring technology, which is applied in the direction of printed circuit components, electrical components, printed circuit components, etc., can solve the problem of damaging the flatness of the wiring body, and achieve the effect of suppressing wetting expansion and excellent flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be described below based on the drawings.

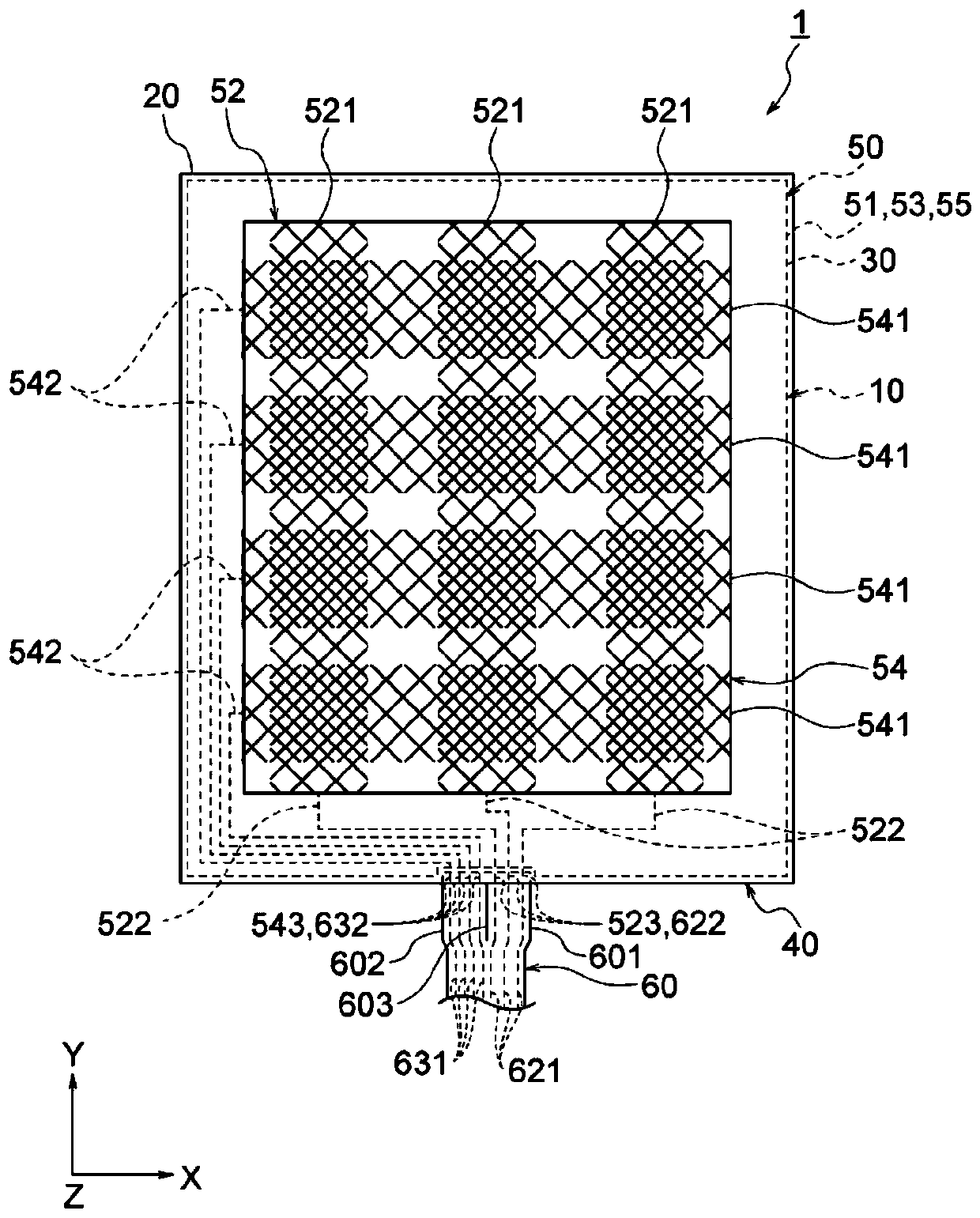

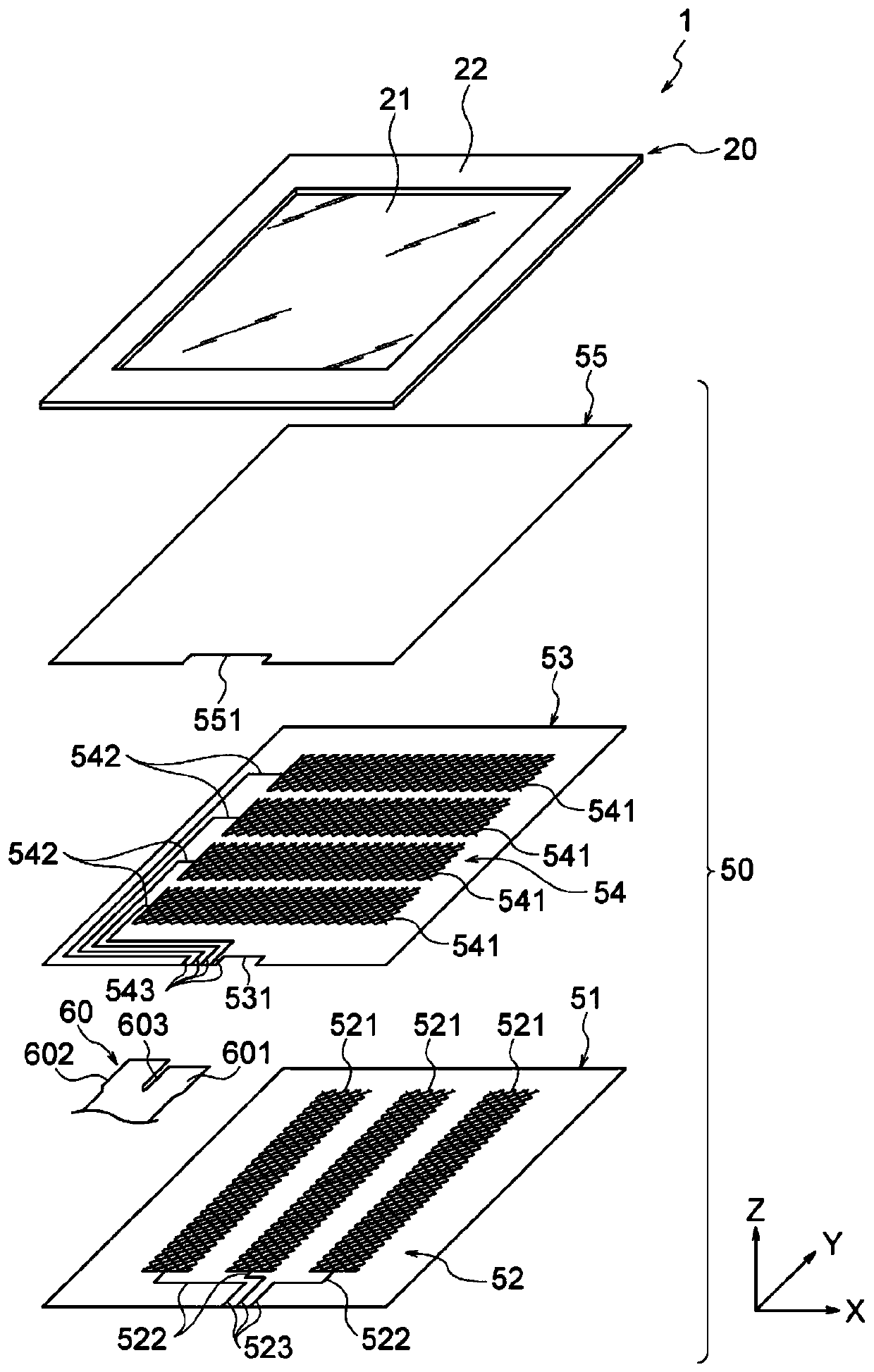

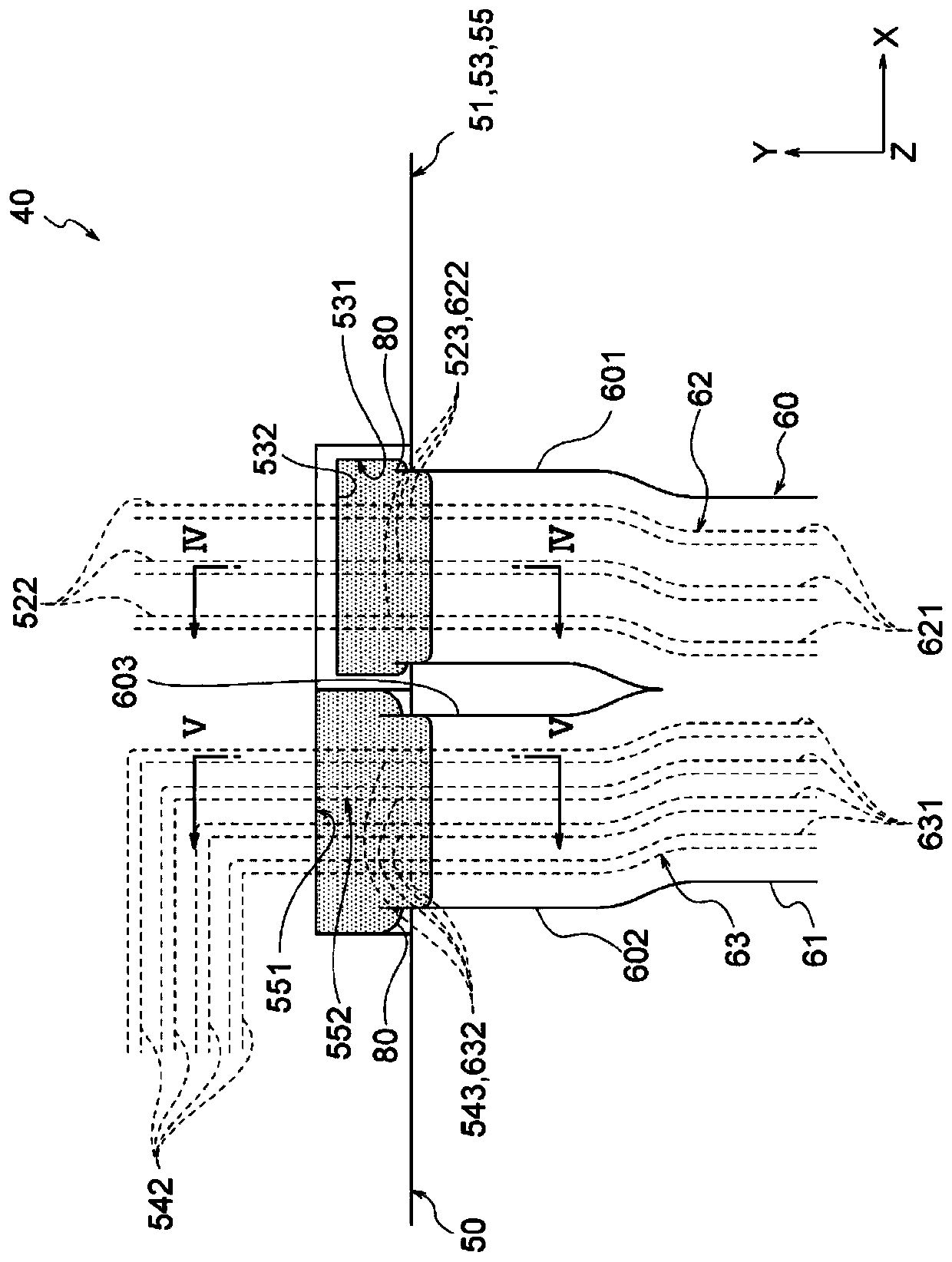

[0039] figure 1 is a plan view showing a touch sensor according to an embodiment of the present invention, figure 2 is an exploded perspective view of its touch sensor, image 3 It is a plan view showing an enlarged connection portion between the first wiring body and the second wiring body.

[0040] figure 1 The illustrated touch sensor 1 is a projected capacitive touch panel sensor, and is used as an input device having a function of detecting a touch position in combination with a display device (not shown), for example. The display device is not particularly limited, and liquid crystal displays, organic EL displays, electronic paper, and the like can be used. This touch sensor 1 has detection electrodes and drive electrodes (first and second electrode portions 521 and 541 described later) arranged to face each other. (not shown) A predetermined voltage is periodically applied...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com