Manufacturing method of electronic components

A manufacturing method and technology of electronic components, applied in transformer/inductor parts, electrical components, inductance/transformer/magnet manufacturing, etc., can solve the problems of forming external electrodes and inability to plate, and achieve the effect of inhibiting liquid wetting and expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0092]

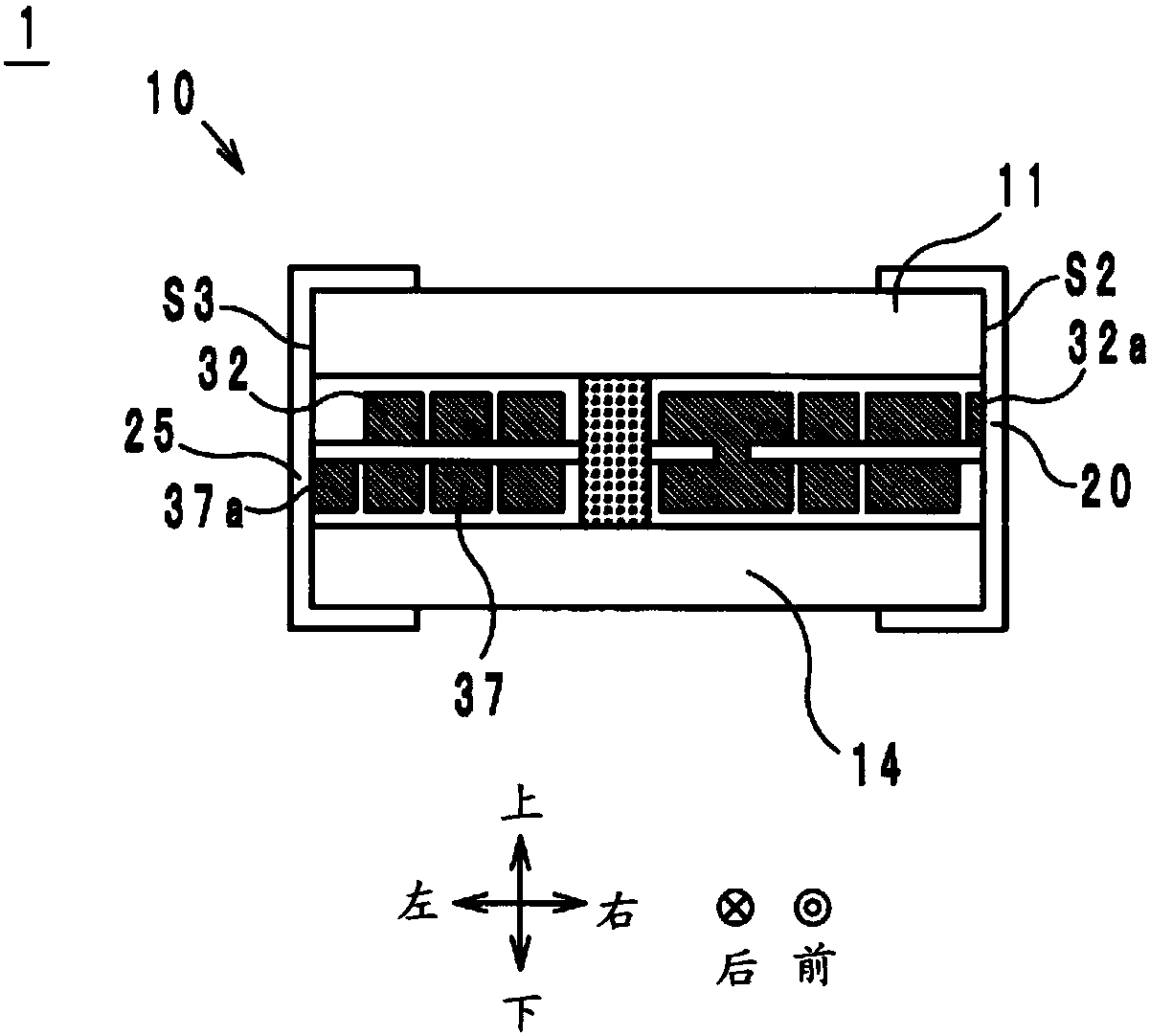

[0093] First, 100 objects including a main body formed of a composite material of metal magnetic powder and resin, and a coil arranged inside the main body with its end exposed from the main body were prepared. Then, the object is inserted into the hole H3 of the mask 200 using a fluororesin for the rubber N so that both ends of the object are exposed from the mask 200 . The mask 200 with the object inserted into the hole H3 is dipped in the conductive solution, and the conductive solution is attached to both ends of the object (in other words, the portion exposed from the mask 200 ). Thereafter, the object is dried, taken out from the mask 200, and subjected to plating treatment to form a plated film on both ends of the object. When 100 objects were observed with a stereo microscope, the coating was peeled off from 12 objects.

[0094]

[0095] A plating film was formed on the object in the same manner as in Example 1, except that rubber N was used and a silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com