Gearbox rework support frame and assembling and disassembling method thereof

A technology of a gearbox and a support frame is applied in the field of gearbox maintenance aids, which can solve the problems of difficulty in rework for replacement and maintenance of gearboxes, high labor intensity of personnel, and difficulty in rework and maintenance of automobiles, and achieves simple structure, low cost, and durability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention will be further described:

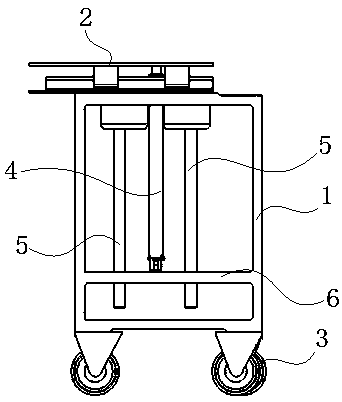

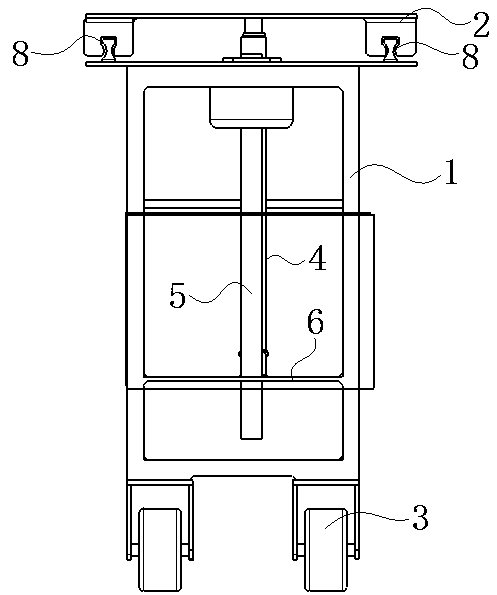

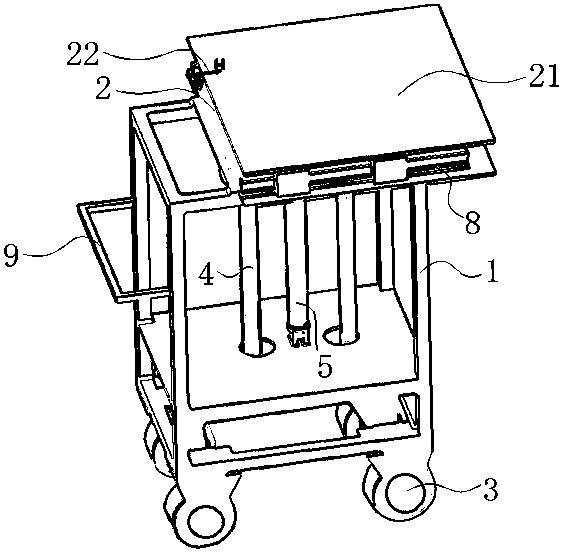

[0035] Figure 1 to Figure 3 It shows a gearbox rework support frame, which is applied to the installation and disassembly of the current automobile gearbox; the support frame includes a support mechanism 1, a workbench 2, a sliding wheel 3 and a lifting mechanism; the workbench 2 is arranged on the support mechanism 1 the top, and can slide in the horizontal direction; the lifting mechanism is arranged on the support mechanism 1, and can drive the workbench 2 to move up and down in the vertical direction, so as to adjust the installation or disassembly height of the gearbox 7; the above scheme can improve The installation and disassembly maintenance efficiency of the existing automobile gearbox reduces the maintenance cost and difficulty. The structure is relatively simple and practical, and the material cost is low.

[0036] Preferably, in combination with the above sch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com