Internal heating three-cylinder vacuum drying cabin

A technology of vacuum drying and drying chamber, which is applied in the direction of heating devices, drying solid materials, lighting and heating equipment, etc. It can solve the problems of low heat exchange efficiency of heat energy, uneven drying moisture, etc., and achieve the effect of avoiding sealing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

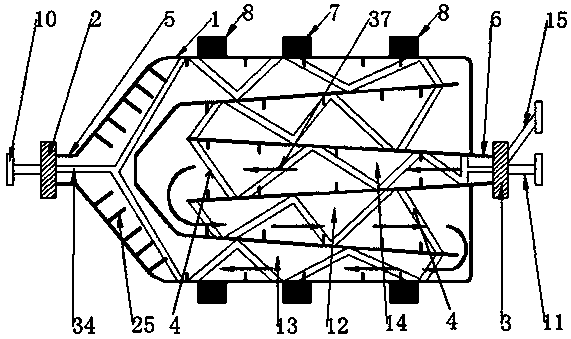

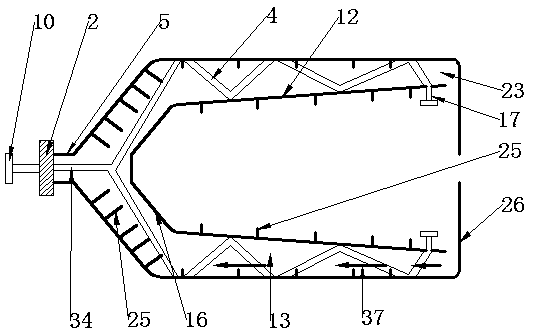

[0107] Such as figure 1 The shown internally heated three-cylinder vacuum drying chamber includes a three-cylinder drying chamber 1 , a feeding device 3 , a discharging device 2 , a plate heating device 4 , a gear ring 7 and a raceway 8 .

[0108] The appearance shape of the three-barrel drying bin 1 is cylindrical.

[0109] The diameter of the three-barrel drying bin 1 is 1800mm; the length of the three-barrel drying bin 1 is 8000mm.

[0110] The raceway 8 is sleeved on the outside of the three-cylinder drying bin 1, and the raceway 8 and the three-cylinder drying bin 1 are fixed as one.

[0111] The gear ring 7 is sleeved on the outside of the three-tube drying bin 1, and the gear ring 7 and the three-tube drying bin 1 are fixed as one.

[0112] Such as figure 1 The three-cylinder drying bin 1 shown includes an outer drying cylinder 13 , a middle drying cylinder 12 , an inner drying cylinder 14 , and a spiral blade 25 .

[0113] The inner drying cylinder 14 at one end of...

Embodiment 2

[0185] The inner-heating three-cylinder vacuum drying chamber of the present invention comprises a three-cylinder drying chamber 1 , a feeding device 3 , a discharging device 2 , a plate heating device 4 , a gear ring 7 and a raceway 8 .

[0186] The combination structure of the three-cylinder vacuum drying chamber with internal heating in Example 2 is the same as the three-cylinder vacuum drying chamber with internal heating introduced in Embodiment 1, so the introduction will not be repeated here.

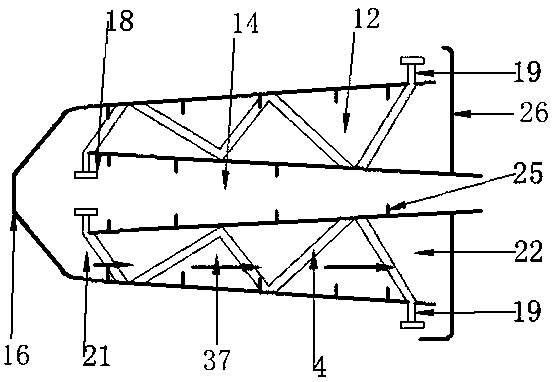

[0187] Such as figure 1 , Figure 5 The shown heat conduction hollow plate 40 is composed of two side plates 39 , two triangular baffle plates and a bottom plate 36 to form a triangular three-dimensional heat conduction hollow plate.

[0188] The upper ends of two side plates 39 and two triangular baffle plates are fixed together. Two side plates 39 are on both sides, base plate 36 is fixed on the lower end of two pieces of side plates 39, and the two ends of two pieces of side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com