Six-million high-resolution zoom lens

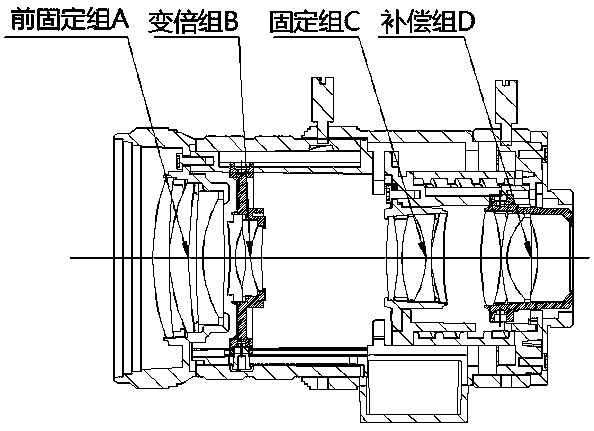

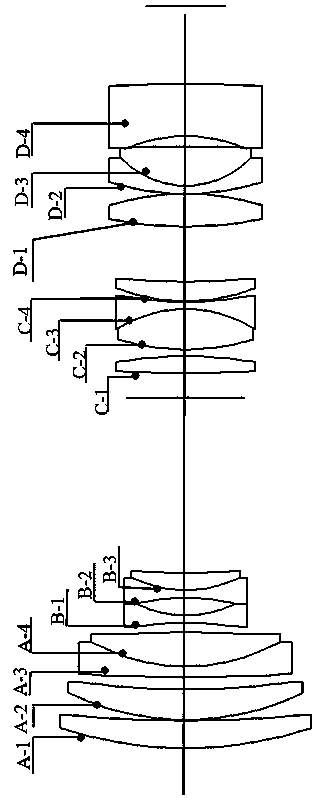

A zoom lens and high-resolution technology, which is applied in the field of 6 million high-resolution zoom lenses, can solve the problems of not being suitable for four-element zoom lenses and not being able to meet the needs, so as to achieve good hand feeling, ensure performance stability and aesthetics , image stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

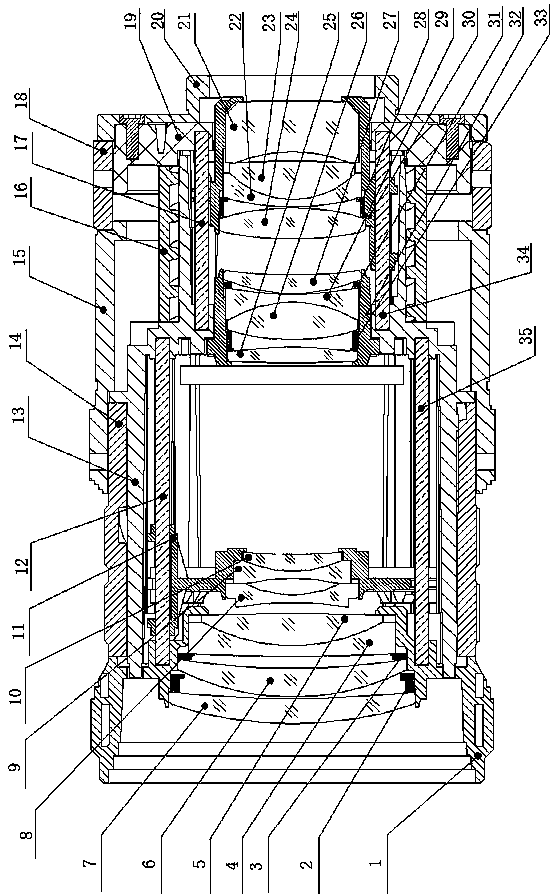

[0051] Embodiment 2: In this embodiment, on the basis of Embodiment 1, the lens housing includes a main lens barrel 13 located in the middle, and the front side of the main lens barrel 13 is fixedly connected with the front group for fixing the front fixed group A lens Lens barrel 1, the rear side of the main lens barrel 13 is fixedly connected with a rear fixed group mirror seat 32 for fixing the fixed group C lens, the first guide rod (12, 35) is fixed inside the main lens barrel, and the first A guide rod (12, 35) is slidably fitted with a zoom group lens holder 11 between the front group lens barrel and the rear fixed group mirror holder, and the zoom group mirror holder 11 has a A matching guide groove, the second guide rod is also fixed on the rear side of the rear fixed group mirror base in the main lens barrel, and the rear side of the rear fixed group mirror base also has a position and a second guide rod (17, 34) Sliding quota and compensation group lens holder 30, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com